The Core Value: A Framework for Strategic De-Risking

While cost savings from avoiding high Non-Recurring Engineering (NRE) costs are an obvious benefit, the true value of low-volume assembly lies in its strategic advantages. It allows you to systematically eliminate uncertainty across four critical domains:

-

1. Design & Engineering Validation: It provides the first real-world test of your Design for Manufacturability (DFM) and Design for Assembly (DFA). A low-volume run with a competent partner will uncover subtle but critical issues—component spacing, solderability problems, test point accessibility—that are invisible on a workbench prototype. Catching these flaws here saves hundreds of thousands of dollars in potential rework and delays down the line.

-

2. Market & User Validation: Low-volume production enables a pilot run or controlled product launch. This provides an invaluable feedback loop from real users before you are locked into a high-volume inventory. You can test pricing strategies, gather user experience data, and confirm product-market fit. This data-driven approach is infinitely superior to launching based on assumptions.

-

3. Supply Chain Validation: A low-volume run is a live-fire stress test of your bill of materials (BOM) and component sourcing strategy. It reveals potential issues with component availability, lead times, counterfeit parts, and supplier reliability. It allows you to vet and qualify alternative components in a controlled environment, building a resilient and cost-effective supply chain for future scaling.

-

4. Manufacturing Process Validation: This is your opportunity to evaluate your assembly partner's capabilities. A successful low-volume run validates their communication protocols, engineering support, quality control systems (like AOI and X-Ray inspection), and logistics. It builds the foundation of trust and operational fluency required for a seamless transition to higher volumes.

The Expert's Evaluation Framework: Selecting a World-Class Partner

Choosing a low-volume quick turn assembly partner, particularly in a hub like China, requires a more sophisticated evaluation than simply comparing quotes. Price is a factor, but a focus on cost-per-unit alone often leads to disastrous outcomes. An expert assesses a partner based on their ability to deliver value and mitigate risk throughout the process.

Use this evaluation checklist:

- Engineering Acumen & DFM Support: Do they provide a comprehensive, free DFM analysis before you place an order? A premier partner acts as an extension of your engineering team, proactively identifying and helping you resolve potential manufacturing issues in your Gerber and BOM files. Vague or superficial DFM feedback is a major red flag. For a detailed guide on these principles, read NextPCB's article on Building Better PCBs: Key Design Strategies and Modern Manufacturing Tips.

- Transparent & Robust Component Sourcing: Ask direct questions about their sourcing channels. Do they have established relationships with authorized distributors (e.g., Digi-Key, Mouser, Arrow)? How do they ensure component authenticity and manage the risk of counterfeit parts? A partner should provide full transparency into their sourcing process and be able to offer strategic advice on component selection and substitution. Learn more in NextPCB's PCBA Manufacturing Process: Full-Step Guide, which details the integrated sourcing and quality control steps.

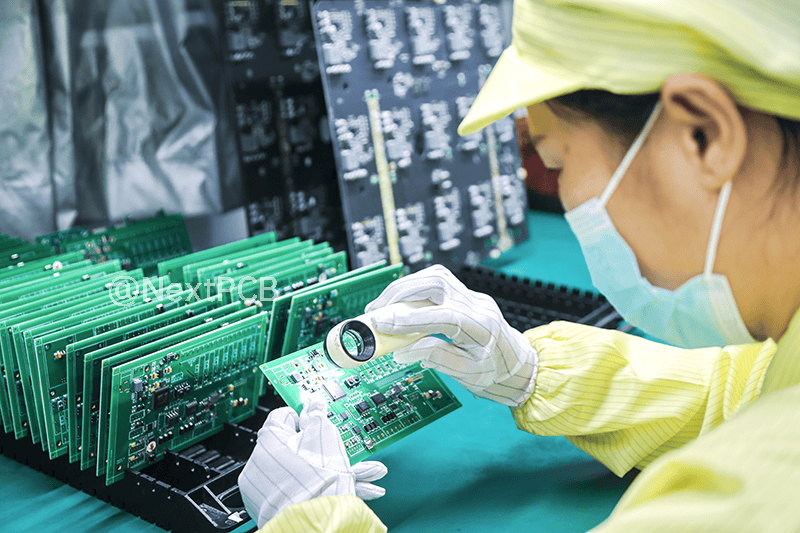

- Advanced Quality Control & Testing Infrastructure: What is their standard QC protocol? At a minimum, this should include Automated Optical Inspection (AOI) for all SMT assemblies. For more complex boards, especially those with BGA components, inquire about their X-ray inspection capabilities. For an in-depth look at these methods and more, read NextPCB's guide on PCBA Test Methods by Category.

- Proactive Communication & Project Management: You are not buying a commodity; you are entering a technical partnership. Is there a dedicated, English-speaking engineer or project manager assigned to your account? How responsive are they? The best partners provide regular updates, ask clarifying questions, and make you feel integrated into the process, not kept at arm's length.

The Process Demystified: From Quote to Delivery

A professional low-volume assembly process should follow a clear, logical progression designed to maximize efficiency and minimize errors.

1. Quote & Initial Files Submission: Provide your Gerber files, Bill of Materials (BOM), and Pick-and-Place (Centroid) file.

> Want to Build a Killer PCBA BOM? Here's Your Step-by-Step Guide

> Need help preparing your files? Check out this guide on How to Generate Gerbers from KiCad.

2. Detailed DFM/DFA Review: Your partner's engineers conduct a thorough analysis and return a detailed report with actionable feedback. This is a collaborative step.

3. Component Sourcing & Confirmation: Once the design is finalized, the partner procures all components, providing a confirmation list and flagging any lead time or availability issues. A key benefit of working with a professional partner is their ability to leverage their buying power to secure components and ensure authenticity.

4. Manufacturing & Assembly: This phase includes solder paste stenciling, automated pick-and-place, reflow soldering, and any necessary manual/through-hole assembly.

5. Quality Control & Testing: The assembled boards undergo rigorous inspection (AOI, X-Ray) and any functional testing you have specified. For low-volume, Flying Probe Testing is a cost-effective alternative to ICT. Lezrn more differences between FCT & ICT.

6. Final Packaging & Logistics: Boards are professionally packaged and shipped, with all documentation provided. NextPCB offers fast delivery with partners like FedEx and DHL, with delivery times to the US as fast as 3-5 days. For more on this, see Fast PCB Assembly Near You? NextPCB Delivers to USA in 3-5 Days!.

By reframing low-volume PCB assembly from a simple production run into a core strategic activity, you transform it from a cost center into a powerful engine for innovation. It is the single most effective tool for ensuring that when you decide to scale, you do so with a fully validated product, a resilient supply chain, and a proven manufacturing process—the true formula for success in the competitive hardware landscape.