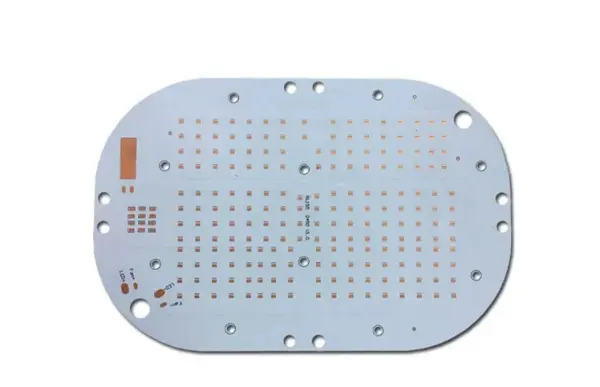

PCBs with aluminum metal core for efficient heat dissipation in high‑power designs.

- - Excellent thermal management and durability

- - Lightweight and cost‑effective

- - Good choice for LED/power electronics

- - Metallic core also helps EMI control

Support Team

Feedback:

support@nextpcb.com

In the world of high-performance electronics—particularly in RF (Radio Frequency) and Microwave applications—"Rogers PCB" is a name that commands respect. For many engineers, it is not just a brand; it is synonymous with high frequency, high speed, and superior reliability.

This guide provides an in-depth look at Rogers PCBs, comparing them with standard materials and providing a detailed specification list of Rogers materials available at NextPCB.

A Rogers PCB refers to a printed circuit board manufactured using laminates produced by the Rogers Corporation. Unlike traditional FR-4 boards, which use epoxy resin and glass fiber, Rogers laminates are typically based on ceramics, hydrocarbons, or PTFE (Polytetrafluoroethylene) composites.

These materials are engineered to maintain extremely low signal loss and a highly stable Dielectric Constant (Dk) even at very high frequencies (up to 110 GHz).

Source: https://www.rogerscorp.com/advanced-electronics-solutions/ro4000-series-laminates/ro4000-lopro-laminates

While Rogers materials come at a higher cost than standard FR-4, they offer specific performance characteristics that are non-negotiable for designs operating above 500MHz.

| Feature | Rogers Material (e.g., RO4350B) | Standard FR-4 | Performance Impact |

|---|---|---|---|

| Frequency | Ideal for > 1GHz (RF/Microwave) | Typically < 1GHz | Rogers maintains signal clarity at high frequencies. |

| Dissipation Factor (Df) | Very Low (~0.0037) | Higher (~0.020) | Rogers minimizes signal transmission loss. |

| Dielectric Constant (Dk) | Stable & Precise | Fluctuates | Rogers allows for precise impedance control. |

NextPCB Expert Tip: To balance performance and budget, consider a Hybrid Buildup. Use Rogers material for critical signal layers and standard FR-4 for power/ground layers.

> Not sure whether to choose Rogers or FR4 for your design? Read our practical Rogers vs FR4 guide (Dk/Df, cost, and hybrid stackup decision matrix)

At NextPCB, we understand that selecting the right material is the first step to a successful RF design. NextPCB’s PCB manufacturing capabilities cover both PTFE and non-PTFE Rogers laminates for consumer to extremely high-frequency applications.

Below is a list of the most popular Rogers materials we support. For other low-loss options, you can also view our high-speed materials.

| Material Code | Brand | Max Freq | Df (@10GHz) | Dk (@10GHz) | Tg/Td (°C) | CTE (ppm/°C) X/Y/Z | Type | Datasheet |

|---|---|---|---|---|---|---|---|---|

| RO4003C | ROGERS | 30 GHz | 0.0027 | 3.38 | 280 (TMA) | 11 / 14 / 46 | Hydrocarbon / Ceramic / Woven Glass | RO4003C.pdf |

| RO4350B | ROGERS | 30 GHz | 0.0037 | 3.48 | 280 (TMA) | 14 / 16 / 50 | Hydrocarbon / Ceramic / Woven Glass | RO4350B.pdf |

| RO3003 | ROGERS | 77 GHz | 0.0013 | 3.00 | 500 (TGA) | 17 / 16 / 25 | PTFE + Ceramic Filling | RO3003.pdf |

| RO5880 | ROGERS | 110 GHz | 0.0009 | 2.20 | 500 (TGA) | 22 / 28 / 173 | Reinforced PTFE | RO5880.pdf |

| RO5870 | ROGERS | 110 GHz | 0.0012 | 2.33 | 500 (TGA) | 31 / 48 / 237 | Reinforced PTFE | RO5870.pdf |

| Specification Item | Technical Capabilities / Details |

|---|---|

| Layer Count | 2-6 layers; supports pure multilayer and hybrid stack-ups |

| Board Thickness | 0.203mm - 2.4mm (refers to base substrate thickness for 2-layer boards) |

| Material Types | Rogers 4350B, Rogers 4003C |

| Min. Trace Width/Spacing | 3.5mil / 3.5mil |

| Min. Hole Size | 0.15mm |

| Solder Mask Colors | Green, Blue, Red, Yellow, Black, Matte Black, White |

| Via Coverage | Via plugging with ink, via plugging with resin + copper capping (POFV) |

| Surface Finish | ENIG (1μ" - 3μ"), OSP, Immersion Tin, Immersion Silver |

| Special Processes | Castellated holes (half-cut), Edge plating, Press-fit holes, Blue mask, Carbon ink |

| Testing Methods | AOI + 4-wire low resistance flying probe full testing |

| Property | RO4003C LoPro |

RO4350B LoPro |

Direction | Units | Condition | Test Method |

|---|---|---|---|---|---|---|

| Dielectric Constant, εr Process |

3.38 ± 0.05 | 3.48 ± 0.05 | Z | - | 10GHz/23°C | IPC-TM-650 2.5.5.5 Stripline Resonator |

| Dielectric Constant, εr Design |

3.50 | 3.55 | Z | - | 8-40 GHz | Differential Phase Length Method |

| Dissipation Factor tan δ |

0.0027 0.0021 |

0.0037 0.0031 |

Z | - | 10GHz/23°C 2.5GHz/23°C |

IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of εr | +40 | +50 | Z | ppm/°C | -50 to 150°C | IPC-TM-650 2.5.5.5 |

| Volume Resistivity | 1.7 x 1010 | 1.2 x 1010 | MΩ•cm | COND A | IPC-TM-650 2.5.17.1 | |

| Surface Resistivity | 4.2 x 109 | 5.7 x 109 | MΩ | COND A | IPC-TM-650 2.5.17.1 | |

| Electrical Strength | 31.2 (780) |

31.2 (780) |

Z | KV/mm (V/mil) |

0.51mm (0.020") |

IPC-TM-650 2.5.6.2 |

| Tensile Modulus | 26,889 (3900) | 11,473 (1664) | Y | MPa (kpsi) | RT | ASTM D638 |

| Tensile Strength | 141 (20.4) | 175 (25.4) | Y | MPa (kpsi) | RT | ASTM D638 |

| Flexural Strength | 276 (40) | 255 (37) | MPa (kpsi) | IPC-TM-650 2.4.4 | ||

| Dimensional Stability | <0.3 | <0.5 | X,Y | mm/m (mils/inch) |

After Etch +E2/150°C |

IPC-TM-650 2.4.39A |

| Coefficient of Thermal Expansion | 11 14 46 |

14 16 35 |

X Y Z |

ppm/°C | -55 to 288°C | IPC-TM-650 2.1.41 |

| Tg | >280 | >280 | °C TMA | A | IPC-TM-650 2.4.24.3 | |

| Td | 425 | 390 | °C TGA | ASTM D3850 | ||

| Thermal Conductivity | 0.64 | 0.62 | W/m/°K | 80°C | ASTM C518 | |

| Moisture Absorption | 0.06 | 0.06 | % | 0.060" thickness 48h immersion 50°C |

ASTM D570 | |

| Density | 1.79 | 1.86 | gm/cm3 | 23°C | ASTM D792 | |

| Copper Peel Strength | 1.05 (6.0) | 0.88 (5.0) | N/mm (pli) | 1 oz. TC after solder float | IPC-TM-650 2.4.8 | |

| Flammability | N/A | V-0 | UL 94 | |||

| Lead-Free Process Compatible | Yes | Yes |

For more information, please see the Rogers official website.

Choosing a Rogers PCB is a commitment to signal integrity. Whether you are designing a 77GHz automotive radar using RO3003 or a cost-effective microwave link using RO4350B, NextPCB has the stock and the manufacturing expertise to bring your design to life.

Ready to start? Visit our Online Quote System to upload your Gerber files, or contact our engineering team for advice on material selection and stack-up design.

PCB is the abbreviation of the...