Introduction:

In the modern world of electronics manufacturing, Automated Optical Inspection (AOI) has evolved from a niche tool to an indispensable asset for quality assurance. As Surface Mount Technology (SMT) and Printed Circuit Board Assembly (PCBA) grow increasingly complex, manual inspection methods struggle to keep pace with demands for speed and precision. AOI testing revolutionizes the process by harnessing high-speed cameras, sophisticated lighting, and intelligent algorithms to automate defect detection. This not only boosts yield rates and production efficiency but also fortifies product reliability across industries. Powered by advancements like AI and 3D imaging, AOI technology is pivotal in maintaining quality control in today's fast-paced manufacturing environments.

In this comprehensive guide, we’ll demystify AOI—exploring its definition, applications, benefits, and future trends—while highlighting how NextPCB leverages its unique advantages to deliver flawless results for clients. Whether you're an engineer, a procurement specialist, or an electronics enthusiast, consider this your holistic roadmap to understanding the true potential of automated PCB inspection.

1. What is the meaning of AOI in testing?

Automated Optical Inspection (AOI) is an automated method based on machine vision, widely used in industries like PCB manufacturing and SMT assembly. Essentially, an AOI machine employs high-resolution cameras, optical sensors, and AI algorithms to quickly capture images of components and compare them against reference standards.

Technical Definition

AOI is a non-contact, non-destructive testing method that employs computer vision technology to compare manufactured products against predefined standards and specifications. The system captures high-resolution images of the inspected items and uses sophisticated image processing algorithms to identify deviations from acceptable quality parameters.

Image Capture

High-resolution cameras capture detailed images of components and assemblies

Processing

Advanced algorithms analyze images for defects and anomalies

Reporting

Detailed reports and classifications of detected defects

The fundamental principle behind AOI testing lies in its ability to perform consistent, repeatable inspections at speeds far exceeding human capabilities while maintaining exceptional accuracy levels. This technology has become indispensable in modern electronics manufacturing, where component miniaturization and increased circuit density demand precision that manual inspection simply cannot achieve.

Visit our PCB Assembly Capabilities page and see NextPCB’s support for SMT, BGA, and mixed THT assemblies.

2. What does AOI check?

AOI systems are designed to detect a comprehensive range of defects and anomalies that can occur during the electronics fabrication process. The inspection capabilities extend across multiple categories of potential issues, each requiring specific detection algorithms and analysis techniques.

2.1 Component Flaws

Component-related defects represent one of the most critical categories of issues that AOI systems must identify. These defects can significantly impact the functionality and reliability of the final product.

Missing Components

- Completely absent components from designated locations

- Partially placed components that fell during reflow

- Components removed during handling processes

Wrong Components

- Incorrect component values or specifications

- Wrong package sizes or orientations

- Mismatched component types

2.2 Solder Joint Abnormalities

Solder joint quality is crucial for electrical connectivity and mechanical stability. AOI systems excel at detecting various solder joint defects that could lead to circuit failures.

Cold Solder Joints

Insufficient heat during reflow process

Bridging

Unwanted connections between adjacent pads

Insufficient Solder

Inadequate solder volume for proper connection

2.3 Solder Paste Issues

Solder paste printing defects are among the most common causes of assembly failures. AOI systems can detect these issues immediately after the printing process, preventing defective boards from proceeding to component placement.

| Defect Type | Description | Impact |

|---|---|---|

| Insufficient Volume | Less solder paste than required specification | Weak solder joints, poor electrical connection |

| Excessive Volume | More solder paste than specification allows | Bridging, short circuits |

| Misalignment | Solder paste not centered on pad | Component misplacement, poor joints |

| Shape Distortion | Irregular paste shape or smearing | Unpredictable reflow behavior |

2.5 Bare PCB Defects

Before component assembly, AOI systems can inspect bare printed circuit boards for manufacturing defects that could affect assembly quality and final product performance.

3. The Core Advantages of AOI

The implementation of AOI technology brings transformative benefits to electronics manufacturing operations. These advantages extend beyond simple defect detection to encompass operational efficiency, cost optimization, and quality assurance improvements.

3.1 High Efficiency

AOI systems can inspect hundreds of components per minute, dramatically reducing inspection time compared to manual methods. This speed advantage enables manufacturers to maintain high throughput while ensuring comprehensive quality control.

- Inspection speeds up to 50x faster than manual inspection

- 24/7 operation capability without fatigue

- Parallel processing of multiple inspection points

3.2 Superior Accuracy

Advanced image processing algorithms and high-resolution cameras enable AOI systems to detect defects as small as 25 micrometers, far exceeding human visual capabilities.

- Detection accuracy rates exceeding 99.5%

- Consistent performance without variation

- Capability to detect microscopic defects

3.3 Enhanced Traceability

Digital inspection records provide complete traceability of quality control processes, enabling manufacturers to track defects, analyze trends, and implement continuous improvement strategies.

- Complete digital inspection records

- Statistical process control integration

- Historical trend analysis capabilities

3.4 Cost Reduction

Early defect detection prevents costly rework and reduces warranty claims, while automated inspection reduces labor costs and improves overall manufacturing efficiency.

- Reduced rework and scrap costs

- Lower labor requirements for inspection

- Decreased warranty and field failure costs

3.5 Consistent Reliability

Unlike human inspectors who may experience fatigue or inconsistency, AOI systems maintain constant performance levels throughout their operation, ensuring reliable quality control regardless of production volume or time constraints.

- 99.8% Repeatability Rate

- 24/7 Operation Capability

- Zero Fatigue Factor

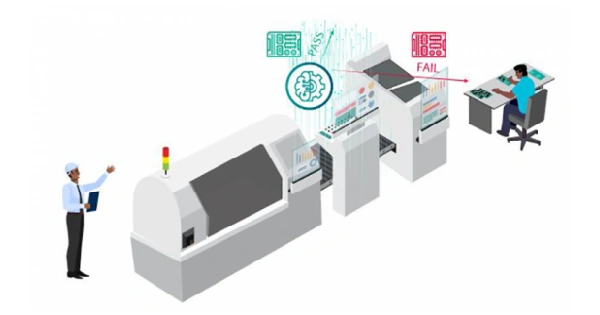

4. How AOI Works: The Inspection Process

Understanding the AOI inspection process is crucial for optimizing its implementation and maximizing its benefits. The process involves four distinct stages, each contributing to the overall effectiveness of the quality control system.

4.1 Image Acquisition

The inspection process begins with high-resolution image capture using specialized cameras and lighting systems. This stage is critical as the quality of captured images directly impacts the accuracy of defect detection.

Camera Systems

- High-resolution CCD or CMOS sensors

- Multiple camera angles for comprehensive coverage

- Specialized lenses for different magnification levels

- Color and monochrome imaging capabilities

Lighting Technology

- LED arrays with programmable intensity

- Multiple lighting angles (top, side, ring)

- Structured light for 3D measurements

- Wavelength-specific illumination

4.2 Data Comparison

Captured images are processed using sophisticated algorithms that compare the actual assembly against predefined reference standards and acceptable tolerance ranges.

4.3 Defect Classification

Identified anomalies are classified into specific defect categories, allowing for targeted corrective actions and process improvements.

- Critical: Immediate attention required

- Major: Significant impact on quality

- Minor: Cosmetic or minor issues

- Pass: Within acceptable limits

4.4 Report Output

The final stage generates comprehensive reports that provide detailed information about inspection results, defect locations, and statistical analysis for process improvement.

Report Components

- Defect location coordinates and images

- Statistical summaries and trend analysis

- Pass/fail status for each inspection point

- Process capability indices

- Historical comparison data

- Recommended corrective actions

5. Types of AOI: 2D AOI vs. 3D AOI

The evolution of AOI technology has led to the development of two primary inspection methodologies: 2D AOI and 3D AOI. Each approach offers distinct advantages and is suited for different application requirements and manufacturing environments.

2D AOI Technology

2D AOI systems utilize planar imaging technology to capture top-down views of assemblies. This approach is highly effective for detecting visible surface defects and offers excellent cost-effectiveness for many inspection applications.

Key Capabilities

- Component presence/absence detection

- Polarity and orientation verification

- Solder paste volume and shape analysis

- Surface-level defect identification

Advantages

- Lower initial investment cost

- Faster inspection speeds

- Simpler programming and setup

- Proven reliability in production

3D AOI Technology

3D AOI systems employ advanced laser scanning or structured light projection to capture three-dimensional measurements. This technology provides superior detection capabilities for complex assemblies and hidden defects.

Advanced Features

- Height and volume measurements

- Hidden solder joint analysis

- BGA and QFN inspection excellence

- Coplanarity verification

Superior Performance

- Enhanced defect detection accuracy

- Reduced false positive rates

- Comprehensive inspection coverage

- Future-proof technology investment

6. AOI in PCB and SMT: Key Application Scenarios

AOI technology is strategically implemented at multiple stages throughout the PCB assembly process. Each application point serves a specific quality control purpose and contributes to the overall manufacturing excellence.

Post-Paste Printing AOI

The first critical inspection point occurs immediately after solder paste printing. This early detection prevents defective boards from proceeding to component placement, saving valuable components and reducing waste.

Inspection Parameters

- Solder paste volume accuracy (±20% tolerance)

- Paste shape and edge definition

- X-Y position alignment (±50μm typical)

- Height uniformity across the deposit

Benefits

- Immediate feedback to printing process

- Prevention of component waste

- Stencil condition monitoring

- Process optimization data collection

Component Placement AOI

After component placement but before reflow soldering, AOI systems verify that all components are correctly positioned and oriented. This inspection prevents reflow defects and ensures optimal solder joint formation.

Critical Checks

- Component Presence: Verification that all required components are placed

- Orientation: Correct polarity and rotational alignment

- Position Accuracy: X-Y placement within specified tolerances

Post-Reflow SMT AOI

The most comprehensive inspection occurs after the reflow soldering process. This stage evaluates the final quality of solder joints and identifies any defects that occurred during the thermal process.

Solder Joint Analysis

- Fillet shape and size evaluation

- Wetting angle measurements

- Void detection and quantification

- Joint strength indicators

Defect Detection

- Bridging between adjacent pads

- Insufficient or excessive solder

- Cold solder joints

- Component tombstoning

Final PCB AOI

The final inspection stage provides comprehensive quality verification before packaging and shipment. This inspection ensures that all previous process steps have been completed successfully and the product meets all specifications.

Comprehensive Final Check

Final AOI inspection combines all previous inspection criteria with additional checks for overall assembly quality, cleanliness, and compliance with customer specifications.

7. NextPCB's Unique Advantages in AOI Testing

NextPCB has established itself as an industry leader in AOI implementation, combining cutting-edge technology with extensive manufacturing expertise to deliver unparalleled quality assurance solutions for electronics manufacturing.

End-to-End AOI Monitoring

NextPCB implements comprehensive AOI coverage across all critical manufacturing stages, ensuring no defect goes undetected throughout the entire production process.

Paste Printing

Real-time solder paste quality verification

Placement

Component position and orientation validation

Reflow

Comprehensive solder joint analysis

Final QC

Complete assembly verification

Advanced 3D AOI Implementation

NextPCB utilizes state-of-the-art 3D AOI systems that provide superior defect detection capabilities, particularly for complex components like BGAs, QFNs, and high-density assemblies.

- Laser-based height measurement systems

- Sub-micron measurement accuracy

- Advanced shadow-free inspection

- Comprehensive BGA void analysis

AI-Enhanced Detection

Integration of artificial intelligence and machine learning algorithms enables NextPCB's AOI systems to continuously improve detection accuracy and reduce false positive rates.

- Deep learning defect classification

- Adaptive threshold optimization

- Predictive defect analysis

- Continuous algorithm refinement

Transparent Traceability

Complete digital documentation of all inspection processes provides customers with full visibility into quality control procedures and results.

- Real-time inspection dashboards

- Detailed defect imagery and analysis

- Statistical process control charts

- Historical trend analysis reports

Cross-Industry Expertise

Extensive experience across automotive, medical, aerospace, and consumer electronics industries enables NextPCB to tailor AOI solutions to specific industry requirements.

- Industry-specific quality standards

- Customized inspection protocols

- Regulatory compliance assurance

- Application-optimized configurations

Learn More About NextPCB's AOI Capabilities

Discover how NextPCB's advanced AOI solutions can enhance your manufacturing quality and efficiency. Watch our demonstration videos to see our technology in action.

8. Future Trends in AOI

The future of AOI technology is being shaped by rapid advances in artificial intelligence, computing power, and manufacturing automation. These developments promise to revolutionize quality control processes and enable new levels of manufacturing excellence.

AI + AOI Convergence

The integration of artificial intelligence with AOI systems represents the most significant advancement in inspection technology. Deep learning algorithms are transforming defect detection capabilities and enabling predictive quality control.

Deep Learning Applications

- Automated defect classification with 99.9% accuracy

- Self-learning algorithms that improve over time

- Pattern recognition for complex defect types

- Adaptive threshold optimization

Predictive Capabilities

- Process drift prediction before defects occur

- Equipment maintenance scheduling optimization

- Quality trend forecasting and prevention

- Root cause analysis automation

Edge Computing for AOI

Edge computing technology brings real-time processing capabilities directly to the shop floor, enabling immediate decision-making and reducing dependence on centralized computing resources.

Real-Time Benefits

Multi-Modal Inspection

The future of inspection lies in combining multiple technologies to create comprehensive quality control systems. AOI integration with X-ray and other inspection methods provides complete defect coverage.

Technology Integration

- AOI + X-ray (AXI) combined systems

- Thermal imaging integration

- Ultrasonic inspection capabilities

- Electrical test correlation

Enhanced Coverage

- 100% defect detection capability

- Hidden defect identification

- Comprehensive failure analysis

- Reduced inspection time