Gold Fingers

Posted:05:16 PM December 18, 2019

writer: NextPCB

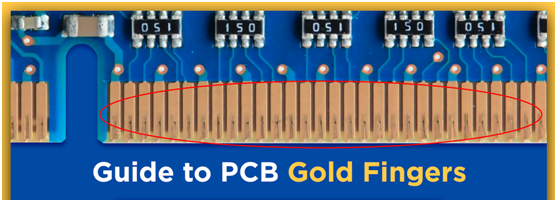

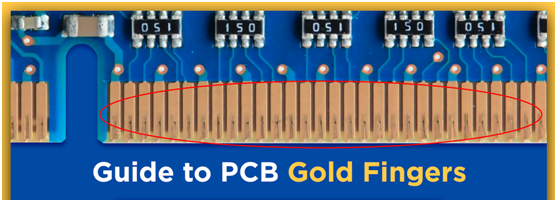

Gold fingers are the gold-plated columns seen along the connecting edges of printed circuit boards (PCBs). The primary use of gold fingers is to connect the secondary PCB to the computer' s motherboard. Please check the following picture for reference.

The usage of the gold finger

PCB gold fingers usually are in various devices that communicate via digital signals, such as smartphones and smartwatches. As the alloy has excellent electrical conductivity, gold is used for PCB connection points. There are two types of gold available for PCB gold finger plating processes. One is electroless nickel immersion (ENIG), it is easier to solder than electroplated and more cost-effective. Another is electroplated hard gold, and it is hard and thick, which makes it more ideal for abrasive effects of constant PCB usage.

Gold fingers are the connecting contacts between different circuit boards. In addition to conductivity, the purpose of the gold fingers is to prevent the connection edges from abrasion in many uses. Gold fingers are multi-functions which includes the following uses:

1. External connections

The outer peripherals added to the computer station are connected to the motherboard by PCB gold fingers. And the devices such as subwoofers, speakers, printers, scanners, and monitors are plugged into specific slots behind the computer tower. These slots are connected to the PCB in turns that connected to the motherboard.

2. Interconnection points

When the auxiliary PCB is connected to the motherboard, it is done through one of several female slots, such as an ISA, PCI, or AGP slot. Through these slots, gold fingers can conduct signals between peripherals or internal cards and the computer itself.

3. Special adapters

Gold fingers can add a lot of performance to a personal computer. The computer can provide enhanced graphics, and high-fidelity sound through the auxiliary PCB inserted vertically into the motherboard.

The significant of the gold finger

Today' s mobile devices and computers are becoming ever-more complex. Numerous gold-plated PCBs will interact at the same time when the computer station with many mobile devices. Because of the function of gold fingers, the motherboard can receive the signals from outer peripheral devices. And the gold fingers make the industry more productive and capable than ever before.

The requirements for the gold finger

The design of gold fingers must conform to some standards as below, no matter what the purpose or size of the PCB is.

- 1. Keep plated through holes away from gold fingers.

- 2. The gold finger should not have any contact with the solder mask or screen printing, and both should keep a certain distance.

- 3. The gold finger must always face the opposite direction from the middle of the PCB.

- 4. Using gold as the connecting fingers, because the alloy has excellent strength and conductivity. The strength of the gold allows fingers to be inserted and ejected hundreds of times without wearing the connection contacts.

- 5. Gold plating should contain 5% to 10% cobalt for maximum rigidity of the edges of the PCB contacts.

- 6. Gold fingers plating should always be in the range of 2 to 50 microinches.

- 7. Gold fingers should pass the visual test of the magnifying glass. The edge should have a smooth, clean surface without the appearance of extra plating or nickel.

The beveling of PCB gold fingers

The beveling of gold fingers is usually made at angles 45 degrees. The angles of 30 to 45 degrees are easier for gold fingers to insert in corresponding slots. For gold fingers that require 45 degrees, certain distances shall be left between the gold fingers and other parts of the board.

Nowadays, more and more amounts of technology rely on gold fingers in PCB prototype and PCB mass production. It is very important to plate and test the gold fingers to the highest standard. NEXTPCB provides turnkey service of PCB assembly with high quality for customers in a variety of industries.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate