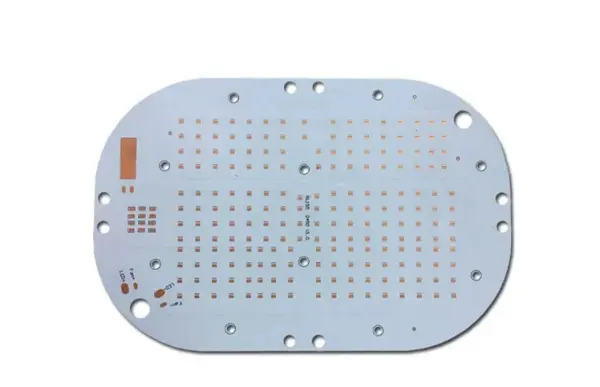

PCBs with aluminum metal core for efficient heat dissipation in high‑power designs.

- - Excellent thermal management and durability

- - Lightweight and cost‑effective

- - Good choice for LED/power electronics

- - Metallic core also helps EMI control

Support Team

Feedback:

support@nextpcb.com

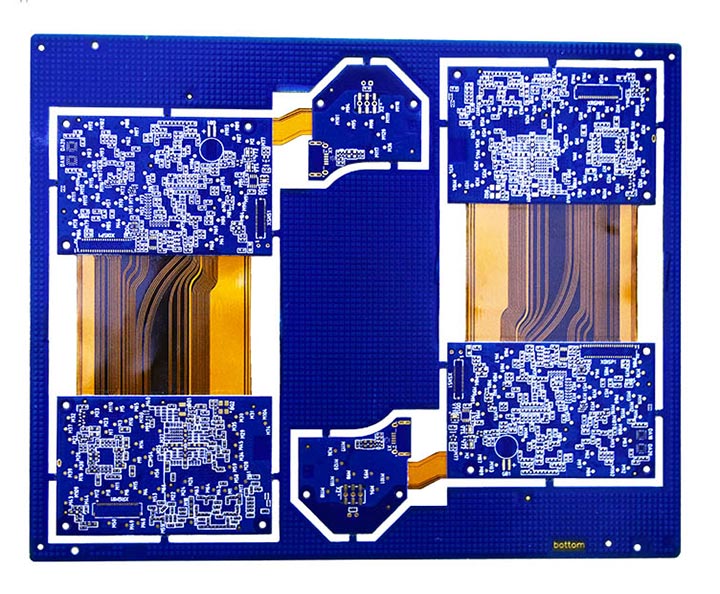

Rigid-flex PCBs are printed circuit boards that integrate both rigid and flex areas into a single interconnected unit. By combining these mechanical opposites, rigid-flex PCBs reap the best of both worlds: the higher density and reliability of rigid PCBs, and dynamic mobility of flex PCBs.

At NextPCB, we provide precision rigid-flex PCB manufacturing and assembly services for compact and dynamic devices spanning medical electronics, wearables, aerospace, or other failure-proof systems. Whether you are looking for the space-saving or signal integrity benefits of rigid-flex constructions, our rigid-flex solutions will enable innovation beyond traditional PCB limits.

Rigid-flex PCBs unlock a host of advantages over standalone rigid, flex or interconnected designs that justify their higher fabrication cost in various applications.

Rigid-flex designs can take advantage of the higher component and signal densities achievable with rigid PCBs, resulting in more compact and lightweight designs compared to rigid assemblies with discrete flex cables, or full flex designs.

With their integrated design, rigid-flex PCBs have fewer points of failure. Connectors and wires can come loose and solder joints can crack over time, so their absence make rigid-flex designs highly suited to environments with high-vibrations or a high number of bend cycles, or in applications where failure is not an option, such as in satellites and medical electronics.

Connectors are interfaces that introduce impedance mismatches and noise that could impact high-speed signals. By eliminating flex cable connectors and using materials with uniform structure and electrical characteristics, dealing with noise, crosstalk and impedance discontinuities becomes much simpler. Flex sections can implement full copper ground planes or conductive films to shield signals as they traverse from rigid sections and rigid flex interfaces are easier to model.

Compared with plain flex PCBs, rigid-flex designs are much easier to handle and assemble since 1) the rigid sections hold the PCB taught in the panel and 2) components are typically positioned on the rigid sections, while flex sections are reserved for signal transfer and bending, reducing alignment issues during PCB assembly and improving reliability. Fixtures may still be required to protect flex sections from excessive heat but their design is typically much simpler.

The lack of flex connectors and wires can also reduce installation labor and BOM costs, especially for larger pin counts or high reliability connectors.

Rigid-flex PCB fabrication, even for simple designs is costly. Since each stack-up is uniquely tied into the design's performance and functionality, it is difficult to combine multiple designs together (no quickturn or pooling services). As a result, prototyping rigid-flex PCB designs remains costly and is less viable for one-off applications.

While boards connected via cables have more points of failure, these points of failure are often easy to repair. Broken connectors, torn cables and even pads can be replaced and solder joints can be reflowed. A rigid-flex PCB with a tear, on the other hand, is very difficult to repair reliably without specialist tools and expertise, meaning the entire assembly has to be replaced. The poor repairability is a reason why you will rarely find rigid-flex designs in cost-sensitive consumer electronics.

Despite the many advantages, rigid-flex PCBs are not practical solutions for all multi-board applications.

The high tooling and upfront costs and difficulty of repair limit rigid-flex designs to applications where reliability and failure-prevention are among the primary decision drivers, such as in aerospace, military or medical applications. Or in high-speed designs where preserving signal integrity necessitates the use of rigid-flex constructions.

Factoring in the high component density and fabrication costs, the upfront costs make rigid-flex designs costly to prototype and unsuitable for one-off designs and cost-effective designs where field repairs could revive units.

NextPCB supports custom rigid-flex PCB manufacture and assembly for boards with up to 32 rigid layers and 6 flex layers with advanced stack-ups and configurations, produced to strict international standards including ISO9001:2015, IATF16949, ISO13485 and IPC6013 Class 3, impedance testing and support. Choose NextPCB for reliable results for your mission-critical products today.

| Feature | Rigid | Flex |

|---|---|---|

| Circuit Layers | 2 to 32 layers | 1 to 6 layers |

| Base Material | FR4 | Polyimide (PI) |

| Covering Type | Solder mask | PI coverlay or flexible solder mask |

| Surface Finishes | ENIG, OSP and Immersion silver | |

| ENIG Gold Thickness | 1 to 3μ" | |

| PCB Thickness | 0.4 to 3.2mm | 0.1 to 0.45mm |

| Copper Thickness | 1 to 6 oz | 1/3 to 1 oz |

| Min. Trace width/spacing | 3/3 mil | 2/2 mil |

| Min. Drill Hole Diameter | 0.1mm | |

| Solder Mask/Coverlay Color | Solder Mask: Green, red, yellow, orange, black, silver and clear | Coverlay: Yellow, white, black and clear |

| Extras |

|

|

Get an instant quote

Please inquire for advanced capabilities.

PCB is the abbreviation of the...