Support Team

Feedback:

support@nextpcb.comIn the fiercely competitive PCB industry, NextPCB is committed to quickly providing customers with high-reliability quality, exceptional service and low-cost PCB manufacturing and PCB Assembly service. Our facilities are certified to IATF16949, ISO13485, ISO9001 and ISO14001 standards, ensuring the highest levels of quality, safety, and environmental compliance. We also comply with UL, RoHS, and REACH regulations for strict material and emissions standards. To help customers verify design projects faster and more effectively, we have introduced a range of special offers and discounts without compromising on quality. Additionally, we provide corresponding free DFM, DFA analysis and Functional Testing service throughout the process to ensure product quality and reliability.

To help customers validate their designs at a lower cost while experiencing our reliable manufacturing processes and professional engineering services, we have created the following special offer:

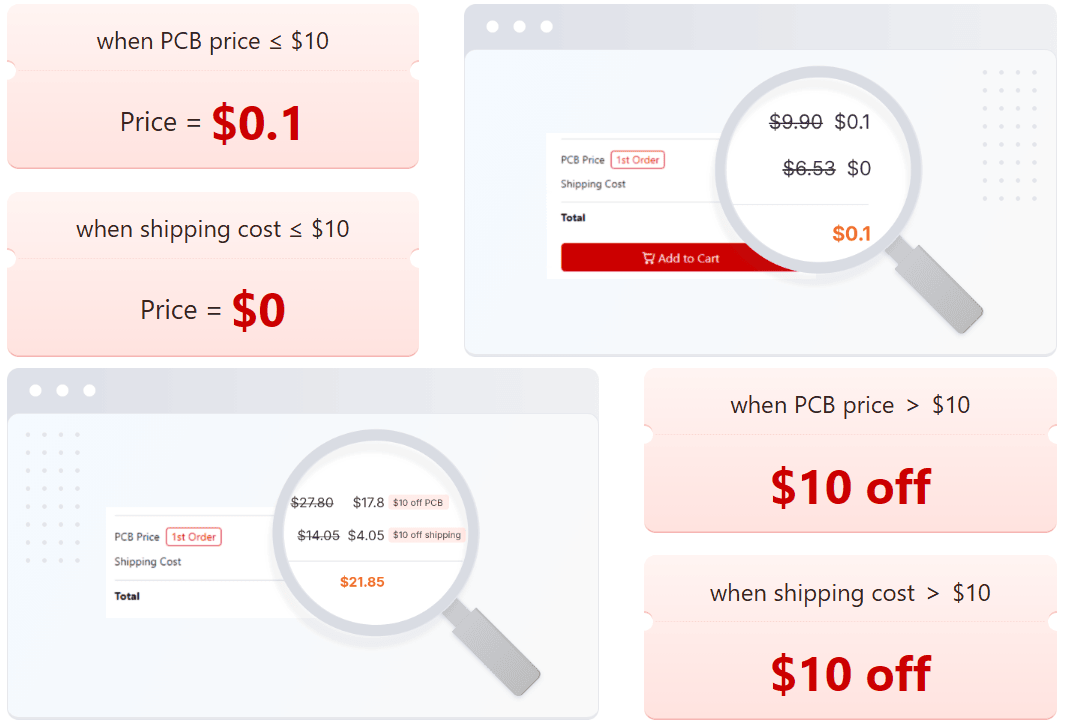

New to NextPCB? Get your designs validated for as low as $0.1, plus save $10 on shipping!

The offers may be canceled at any time. Take advantage of this fantastic opportunity to experience NextPCB's high-quality and exceptional service.

Order PCB Online from $0.1 + Shipping $10 Off

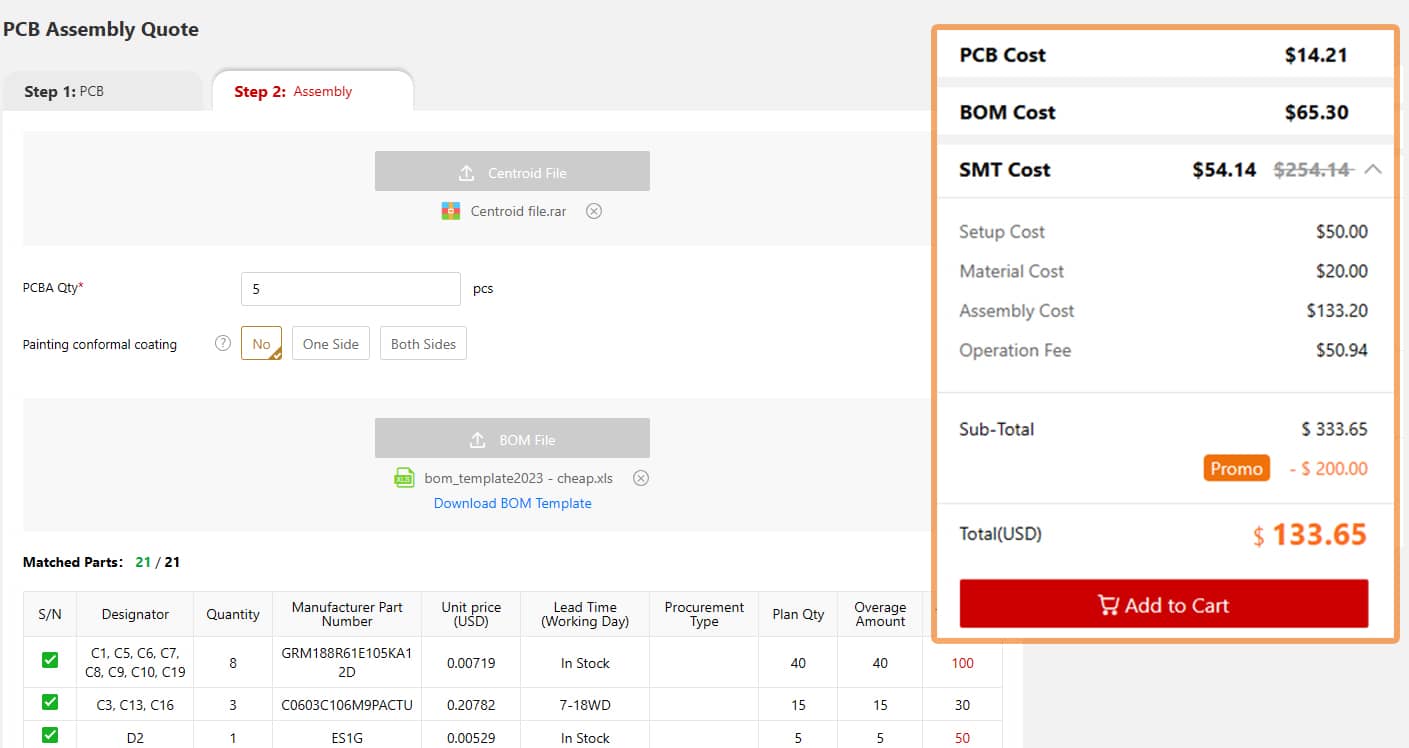

To support developers and innovative teams in efficiently creating prototypes and conducting small-batch testing, NextPCB is now offering PCB assembly services for orders starting from just 1 piece, with up to a $200 discount per order.

NextPCB is proud to hold IATF16949 and ISO13485 certifications, ensuring that our manufacturing processes meet the highest standards of quality and reliability. After assembly, NextPCB also provide free functional testing for up to 10 pieces, ensuring that your prototypes are thoroughly tested and perform as expected before delivery.

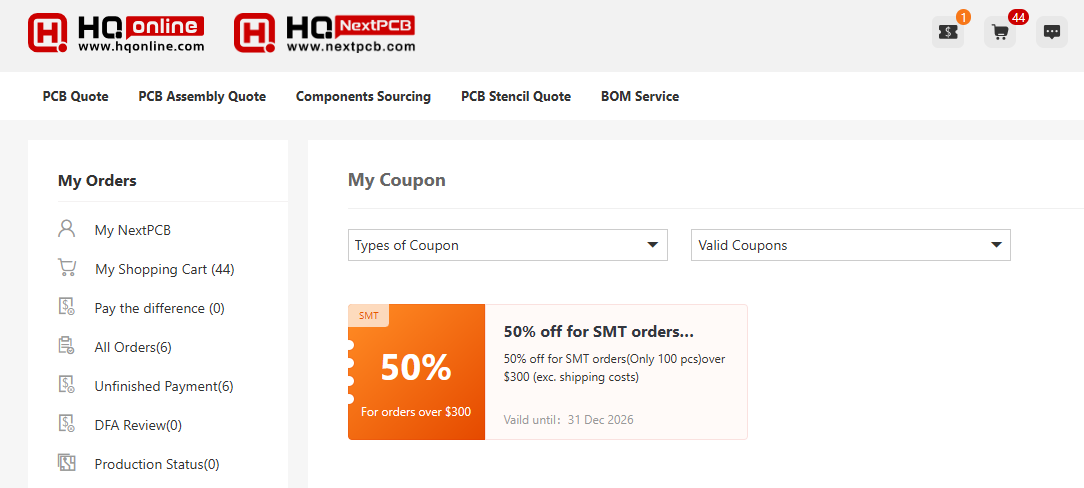

Is 1-10 pieces not enough to validate your project design? Don't worry. NextPCB has created a 50% discount on 100-piece PCB assembly based on our customers' needs.

Seize this opportunity to optimize your production with NextPCB's reliable pcb assembly services, all while enjoying cost savings!

The NextPCB Accelerator campaign is an innovative initiative that empowers creators to bring their ideas to life. Whether you're an entrepreneur or enthusiast, we support your journey from concept to mass production.

While we primarily focus on business-oriented projects, we also welcome hobbyist projects that contribute to the open-source community and showcase RP2040's or RP2350's or Beetle ESP32-C6's or ESP32-S3's capabilities, though they must be your own original design. Publicly available designs do not qualify for sponsorship.

Seize this opportunity to quickly validate your RP2350 / RP2040 or Beetle ESP32-C6 or ESP32-S3 or RAK3172 project design and benefit from our efficient services and substantial sponsorship!

Discover All Sponsored Campaigns

Enjoy free global shipping when you purchase electronic components totaling over $50!

Select the electronic components you need, and enjoy the free global shipping offer on orders over $50. Make your project a success with NextPCB!

NextPCB is committed to providing high-reliability, low-cost PCB and PCB assembly solutions. For mass production, NextPCB has a high value advantage. If you have volume orders requirements, we invite you to contact us for exclusive discounts tailored to your needs. Our volume order discounts include:

If you would like to learn more about vloume order discounts or have any questions, please don't hesitate to reach out by support@nextpcb.com . We look forward to collaborating with you to drive your project's success!

At NextPCB, we prioritize quality and reliability in every product we deliver. Even with our most competitive discounts, the quality remains uncompromised. To ensure our customers achieve high success rates in their project validations, we offer a comprehensive range of services. In addition to critical inspections such as AOI, X-ray, ICT (In-Circuit Testing), Flying Probe Testing, FAI(First Article Inspection), SPI(Solder Paste Inspection) and expert manual visual inspection, we also provide complimentary Design for Manufacturing (DFM), Design for Assembly (DFA), and Functional Testing services to further enhance your project's success.

Quote OnlineView NextPCB CatalogView NextPCB Certificates

Your best alternative PCB manufacturing and assembly house. We balance quality and cost, striving to provide high-value, competitive solutions for your projects. We're more than just a service provider, we're your strategic partner. From prototype to mass production, we offer efficient, precise, one-stop services, providing strong support for your project.

We specialize in the manufacturing and customization of a wide range of high-precision, high-reliability PCBs, including multilayer PCBs, HDI PCBs, rigid-flex PCBs, high-frequency and high-speed PCBs, metal-based PCBs, and heavy copper PCBs. Our capabilities enable us to meet the diverse needs of industries such as consumer electronics, automotive, medical, industrial control, and telecommunications.

Our competitive pricing stems from several key factors that don't compromise quality. We achieve this through:

Economies of Scale: As a large-scale manufacturer, we benefit from significant volume discounts on raw materials and components, which we pass on to our clients.

Optimized Production Processes: We continually invest in advanced automation and lean manufacturing techniques, boosting efficiency and minimizing waste.

Strong Supply Chain Relationships: Our long-term partnerships with trusted suppliers ensure cost-effective procurement and stable material availability.

Specialized Expertise: Our focus on specific PCB types and volumes allows us to optimize our operations for those areas, leading to greater efficiency and lower costs.

Special Prototype Offers: We provide particularly favorable pricing for prototype orders. This is primarily intended to allow you to experience our superior quality and service firsthand, with the ultimate goal of securing your future mass production orders.

Transparent Cost Structure: We aim for clear and fair pricing, building long-term relationships based on trust and value. We believe in offering the best value — a superior balance of quality, performance, and cost-effectiveness — rather than just being the cheapest option.

For PCBs, you can prepare your Gerber file (including drill files) in RS-274X format to get real-time pricing through our powerful 24/7 online pricing system. Get Your PCB Quote Online.

For PCB Assembly, in addition to the Gerber file, please also provide the Bill of Materials (BOM) and the centroid (Pick and Place) file. Then you can get the instant quotation online. Get Your PCBA Quote Online.

Our standard manufacturing capabilities support a minimum trace width/spacing of 2mil/2mil, a minimum mechanical drilling hole size of 0.15mm.

For more advanced or customized requirements, please consult our technical support team — we have the capability to handle more complex processes.

For PCBs, we offer expedited prototyping services with lead times of 24, 48, or 72 hours to meet your urgent needs. Mass production lead times vary depending on order volume and complexity.

For PCBA, the standard lead time is typically 5–20 working days. If all components are available, lead time can be as fast as 24 hours.

After continuous optimization, our on-time delivery rate is as high as 99.59%

We strictly adhere to international quality management systems such as ISO 9001, ISO 13485, UL, ROHS, IATF 16949, etc.. Quality is ensured at every stage — from design review (DFM & DFA) and raw material inspection, to in-process quality control (including AOI, X-ray, ICT), final functional testing, and pre-shipment FQC.

Equipped with advanced inspection equipment and a professional quality management team, we ensure that every product meets 100% of customer requirements.

We ensure end-to-end product traceability through a system of unique identifiers and rigorous data capture. Every product receives a unique mark, like a serial number or QR code. Our Manufacturing Execution System (MES) then tracks and records all critical details—from raw materials and process parameters to quality inspection results (AOI, X-ray, ICT)—for each item. This comprehensive data, combined with our adherence to international quality standards (ISO 9001, ISO 13485, etc.), allows us to fully trace a product's journey. Additionally, we offer a UL Mark service, which can be added to every board, further enhancing product credibility and traceability. This ensures every product meets 100% customer requirements.

If you receive products with quality issues, please contact our customer service team immediately and provide a description of the issue along with relevant photos. We will respond within 24 hours and initiate a professional quality issue handling process, including problem analysis, root cause investigation, solution proposal, and arrangements for compensation or rework as needed — ensuring your rights and interests are fully protected.

Yes, we provide comprehensive full turnkey solutions, which include PCB fabrication, component sourcing, PCB assembly, and final testing. This integrated service allows us to manage your entire project from design files to finished products, streamlining your supply chain, reducing lead times, and ensuring consistent quality. Please share your project details, and our team will provide a tailored solution.

Yes, we specialize in the manufacturing of high-frequency and high-speed PCBs. We understand that the keys to these products lie in signal integrity, impedance control, and material selection. Therefore, we not only strictly adhere to international quality standards such as ISO 9001, ISO 13485, UL, RoHS, and IATF 16949, but also integrate these requirements into our exclusive production processes for high-frequency and high-speed PCBs.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now