Lolly Zheng- Sales Account Manager at NextPCB.com

Support Team

Feedback:

support@nextpcb.comIntroduction:

In 2025, the global electronics industry is undergoing a technological revolution driven by artificial intelligence and green manufacturing, with China at the center of this transformation. For hardware engineers, product designers, and procurement managers, finding the ideal China circuit board manufacturer is no longer just about cost for duty-optimized circuit manufacturing; it requires a comprehensive evaluation of technical capabilities, quality management systems, and supply chain efficiency.

For five consecutive years, China has been the world's largest PCB production base, and by 2025, its output is projected to contribute over 40% of the global total. This dominance stems from its complete industrial ecosystem, particularly in the industrial cluster centered around the Pearl River Delta, which can achieve a rapid 48-hour response time from copper foil to final assembly. This supply chain efficiency is 30% faster than that of Europe and the United States.

In the past, some may have perceived "Made in China" as limited to low-end products. However, with the explosive demand from downstream applications like 5G communication, AI, and new energy vehicles, Chinese PCB manufacturers like NextPCB have accelerated their transition to high-end technologies such as high-layer boards, High-Density Interconnect (HDI) boards, and flexible boards. For instance, due to the surge in demand for 5G smartphones and AI servers, the market share of HDI boards has increased to 16.6%. This indicates that Chinese manufacturers are transforming from "cost followers" into "rule makers" who lead industry change with technological resilience and manufacturing flexibility.

Therefore, choosing the right China circuit board manufacturer means you will gain access to unparalleled economies of scale, an efficient supply chain, and cutting-edge technology that keeps pace with the times.

Table of Contents

To help you make an informed decision, we have created a comprehensive evaluation framework with 8 key checkpoints. This checklist not only measures technical specifications but also covers dimensions such as quality control, communication, collaboration, and business transparency.

When searching for a manufacturer, the first step is to verify the industry standards and certifications they adhere to. These third-party certifications are direct proof of their process maturity, risk management capabilities, and market alignment.

The IPC (Association Connecting Electronics Industries) provides globally recognized performance standards for PCB design, manufacturing, and assembly. The IPC-A-600 and IPC-A-610 standards classify electronic products into three levels.

- Class 2: Intended for "dedicated service electronic products," such as microwaves, laptops, and televisions, where an extended lifespan is desired. These products allow for minor visual imperfections, such as surface-mount components being slightly off the pad, as long as electrical and mechanical performance is not affected, which is deemed acceptable.

- Class 3: Applies to "high-performance/harsh environment electronic products," such as advanced medical devices, clean technology, and aerospace equipment, where product downtime is not an option and reliability is paramount. Compared to Class 2, Class 3 has stricter requirements for component alignment tolerance, through-hole barrel fill (75% vs. 50%), and plating thickness (1 mil vs. 0.8 mil). For example, Class 3 does not permit any annular ring breakouts, while Class 2 does.

UL (Underwriters Laboratories) certification, issued by a third-party organization, is a crucial guarantee of product safety and operability. For PCBs, the most common UL mark is the "UL Recognized Component Mark," which indicates that the circuit board is a component that complies with UL 796 safety standards and can be used in a final product that is UL certified. The UL 94 flammability rating further evaluates the base material's resistance to burning.

A manufacturer with specialized certifications like ISO 13485 (medical device quality management) or IATF 16949 (automotive industry quality management) demonstrates a long-term commitment to serving high-reliability, high-standard industries.

The types of materials a manufacturer offers directly reflect its technical sophistication and ability to handle high-demand designs.

In addition to the most common FR-4 material, a manufacturer should also offer high-Tg (glass transition temperature) materials, low-loss Rogers materials, and metal-core PCBs (MCPCBs) for thermal management in LED lighting and power electronics. For high-frequency and high-speed applications, the manufacturer must be able to work with materials that have a low dissipation factor (Df) to ensure signal integrity.

A well-thought-out PCB layer stack-up can effectively reduce a circuit's sensitivity to external noise, and mitigate radiation, impedance, and crosstalk issues in high-frequency designs, thereby improving the product's electromagnetic compatibility (EMC).

A manufacturer's hard technical parameters are a direct reflection of its equipment investment and engineering strength.

This parameter determines the density of the circuit board design. The current industry-leading standard can reach 3/3 mil, which is made possible by high-precision exposure equipment like Laser Direct Imaging (LDI).

The minimum mechanical drill size (e.g., 0.15mm) and minimum laser drill size (e.g., 0.1mm) directly impact the board's compactness and design freedom.

For high-speed signal transmission, impedance control is critical. A capable manufacturer should provide impedance calculation tools and be able to control impedance tolerance through precise layer stack-ups and production processes.

The ability to support a high number of layers (e.g., 32+ layers) and HDI (High-Density Interconnect) structures, such as blind, buried, and micro-via technologies, is a key indicator of a manufacturer's capacity to handle complex designs.

DFM (Design for Manufacturability) is a crucial step to ensure a design can smoothly transition into mass production.

Top-tier manufacturers provide a free DFM file check system. This automated tool can identify potential issues within minutes, such as insufficient spacing, antenna effects, or unplated vias, preventing the design from being put on "CAM hold" before production.

In addition to automated tools, a secondary review by experienced CAM/DFM engineers is equally important. This combination of automated and manual checks can uncover deeper, hidden issues, which helps reduce costs, improve reliability, and accelerate time-to-market.

In the fast-paced hardware development cycle, lead time is a critical factor that can determine the success or failure of a project.

Typical quick-turn prototyping services can complete the production of single/double-layer boards in as fast as 24 to 72 hours. Faster lead times mean shorter iteration cycles, which is vital for startups and prototype development.

The on-time delivery rate is a core KPI for measuring a manufacturer's operational efficiency and reliability. Leading manufacturers in the industry typically maintain a high on-time delivery rate of 96% to 99%. A professional digital data system can help manufacturers complete file reviews in minutes and scientifically configure production lines to ensure on-time delivery.

A comprehensive quality control process is the ultimate guarantee of product reliability.

Automated Optical Inspection (AOI) uses high-resolution cameras to quickly detect defects on the PCB surface, such as misalignments, shorts, and missing solder.

X-ray inspection can "see through" solid materials to find hidden defects like voids or cracks in BGA solder balls, which is essential for high-density, complex boards.

Electrical testing is crucial for ensuring the board's functionality. Flying probe testing is a flexible, fixture-free, non-contact method suitable for small-volume and prototype testing. In-Circuit Testing (ICT), which uses a fixture for comprehensive electrical probing, is particularly suitable for mass production. By performing a 100% electrical test on every circuit board using these methods, issues like open and short circuits can be effectively prevented.

> Recommend reading: ICT vs FCT: PCBA Test Strategy

Transparent and efficient communication is the foundation for building a long-term partnership.

A manufacturer should provide clear Gerber, BOM, and Centroid file requirements to reduce communication costs and potential errors during file processing.

A healthy partnership relies on quick-responding engineering support. For critical applications, a manufacturer that can provide a quick 2-hour response time can resolve issues more smoothly.

A transparent pricing model is a sign of integrity.

Manufacturers typically offer tiered bulk pricing to meet various needs, from prototyping to large-scale production.

> Recommend reading: Know The Technical Side of PCB Prototyping

The quote should clearly list all costs, including one-time engineering fees (NRE) and the pricing for special processes like windowing and surface finishes, to avoid hidden costs.

To understand how different factors contribute to cost, you can refer to a breakdown of PCB price composition which explains materials, complexity, and process influences on pricing.

During the evaluation process, some obvious "red flags" can help you quickly filter out unreliable suppliers.

If a manufacturer can only provide vague descriptions like "high-quality" or "strong capabilities" but cannot offer specific parameters (e.g., minimum trace width, UL number, on-time delivery rate), it is likely a trader or broker. A true manufacturer will be proud of its technical strength and happy to showcase its high-precision equipment.

If a company cannot provide real numbers or downloadable documents for certifications like ISO, UL, or RoHS, it indicates a significant compliance risk.

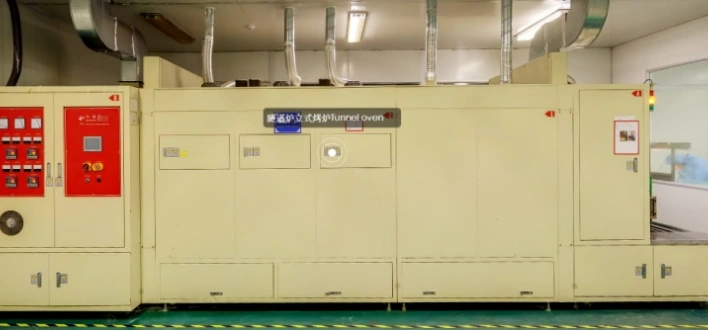

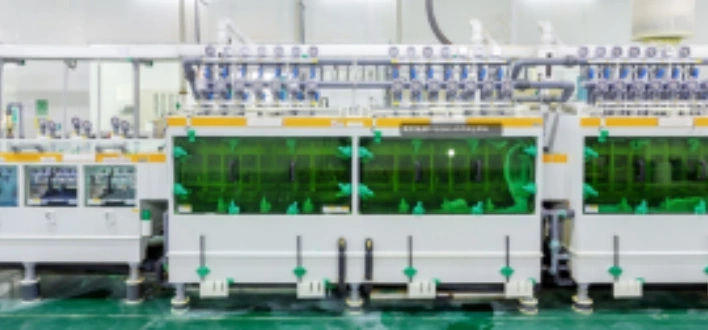

A key differentiator is that a genuine manufacturer can provide photos, videos, or virtual tours of their factory, while traders usually cannot, as they do not own the production equipment.

A reliable manufacturer can provide a complete and verifiable audit trail of its capabilities, processes, and qualifications, which is the core difference between it and a broker or unreliable supplier.

This section maps NextPCB's specific capabilities to the 8 checkpoints above, providing you with a clear and trustworthy reference.

| Checkpoint | NextPCB's Qualifications and Capabilities |

| 1) Qualifications and Standards |

|

| 2) Layers and Materials |

|

|

3) PCB Capabilities, PCBA Capabilities, and Tolerances |

|

| 4) DFM/CAM | Provides a free automated DFM check and a secondary review by experienced engineers. Offers real-time feedback and visual reports. |

| 5) Prototyping and Lead Time |

|

| 6) Quality Control | Uses various methods including AOI, X-ray inspection, flying probe testing, ICT, and functional testing. All boards undergo a 100% electrical test before shipment. |

| 7) Communication and Documentation | Provides clear file requirements and 24/7 technical support. The engineering team responds quickly to file-related issues. |

| 8) Price Transparency | Tiered pricing with an instant online quote system. The cost structure is clear, and you can upload files online for a free quote. |

The following three case studies demonstrate NextPCB's capabilities in different application scenarios by highlighting the specific project challenges, the solutions provided, and the final outcomes.

| Use Case | Key Challenge | NextPCB Solution | Actual Outcome |

| High-Speed Signal Device | Designing a multi-layer HDI board for an AI device that required strict impedance control and high-density routing. | Provided 3/3 mil trace/space, HDI blind and buried via capabilities, and precise impedance control. | Successfully manufactured a high-demand design, ensuring signal integrity for high-frequency signals. The customer praised the "perfect" product. |

| Rapid Iteration IoT Device | A startup needed to quickly iterate on an IoT sensor prototype to accelerate time-to-market. | Offered quick-turn prototyping for 1-2 layer boards in as fast as 24 hours, along with online tracking for the entire process. | The customer was able to perform multiple iterations in a short time and track production progress at all times, which helped turn their idea into a "commercially viable product." |

| High-Reliability Medical Device | Manufacturing a PCB for a new medical device that required the highest level of quality and compliance. | Certified to ISO 13485 (Medical Devices) and ISO 9001 standards, and was able to provide IPC Class 3-level circuit boards. | The boards fully met regulatory requirements and quality standards. The customer reported that "everything works" and was highly satisfied with the quality. |

Choosing your circuit board manufacturer is a crucial step for project success. Here is a simple three-step process to begin a collaboration.

Step 1: Upload Your Files

Upload your Gerber files, BOM list, and pick-and-place files to receive a free automated DFM check and an instant quote.

Step 2: Get a Free DFM Report

You will receive a detailed DFM report that highlights potential manufacturing issues and provides actionable optimization suggestions, helping you save time and cost before production begins.

Step 3: Confirm and Place Your Order

With the assistance of an engineer, confirm the final layer stack-up, surface finish, and all technical details.

> Upload your files now for a free DFM check!

> See standard stack-ups and impedance options.

Here are some frequently asked questions about choosing a China circuit board manufacturer.

Yes, provided you verify the manufacturer's qualifications, such as UL (E469747), ISO 9001, and IATF 16949 certifications. You should also request DFM and quality reports and review their on-time delivery records to ensure operational stability and reliability.

> NextPCB Promise the Product Safety with ISO 9001 UL Certifications

The most important certifications include IPC Class 2/3 capability, UL certification (UL 796), ISO 9001/14001, and RoHS/REACH compliance. For specific industries like medical and automotive, ISO 13485 and IATF 16949 certifications are particularly critical.

For simple single/double-layer boards, quick-turn prototyping can typically be shipped in 24 to 72 hours, depending on the layer count, surface finish, and testing options. Lead times for more complex projects will be longer.

A genuine manufacturer can provide specific, verifiable technical parameters (e.g., minimum trace width, hole size), has real certifications with registration numbers, and can show photos or videos of their factory. Brokers typically cannot provide these specific production details, and their quotes and capability descriptions are often vague.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now