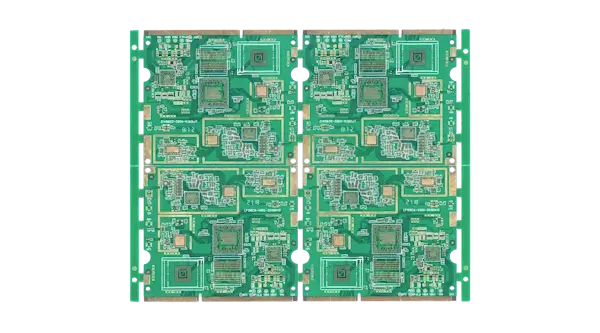

High-TG PCB

Printed circuit boards made with high glass transition temperature (Tg) materials, typically 170°C and above.

- Enhanced thermal resistance and stability

- Improved mechanical strength at high temperatures

- Reduced thermal expansion

- Better chemical resistance

High Frequency PCB

PCBs designed to handle signals in the GHz range with minimal signal loss and distortion.

- Low dielectric constant (Dk) and dissipation factor (Df) materials

- Precise impedance control

- Specialized copper foils with low surface roughness

- Controlled dielectric thickness

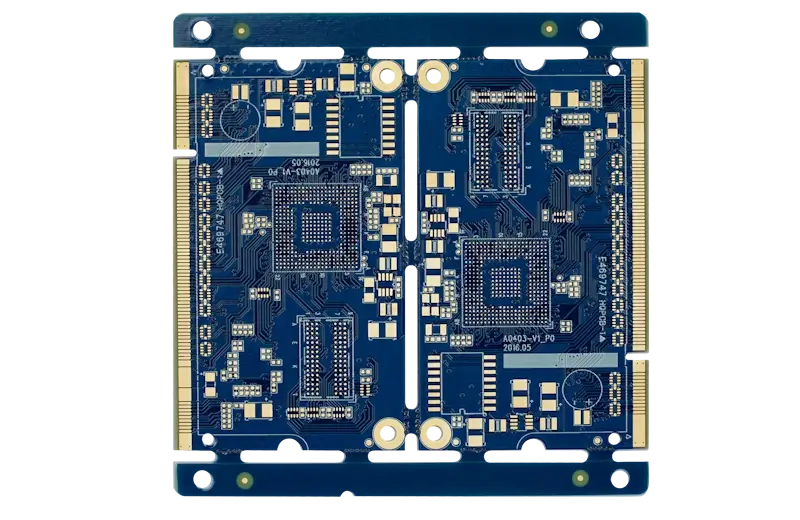

High Speed PCB

Circuit boards optimized for high-speed digital signals with careful attention to signal integrity.

- Low-Dk/Df high-speed laminates (Megatron, Isola)

- Controlled impedance support

- Custom and hybrid stackup support

- Backdrilling & via optimization

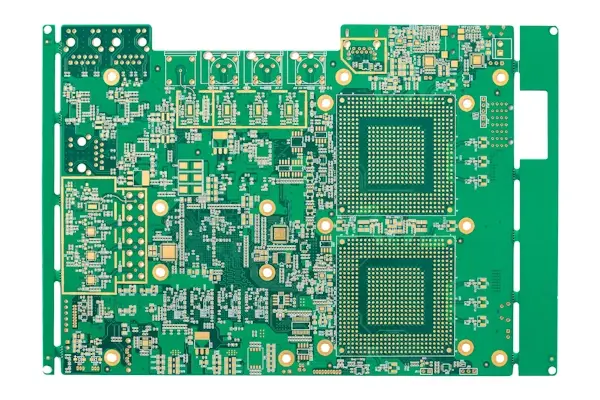

HDI PCB

High Density Interconnect PCBs with finer lines, smaller vias, and higher connection density.

- Microvias (laser-drilled)

- Finer trace widths and spacing

- Higher pad density

- Sequential lamination HDI 3 above

- Any-layer via structures

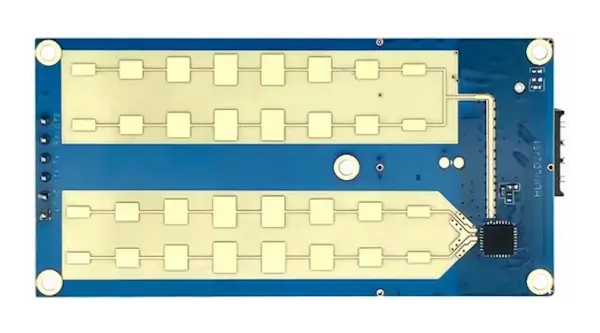

Rogers PCB

PCBs manufactured using Rogers Corporation's high-performance laminate materials.

- Low dielectric loss for high-frequency applications

- Stable electrical properties over temperature

- Low moisture absorption

- Excellent thermal management

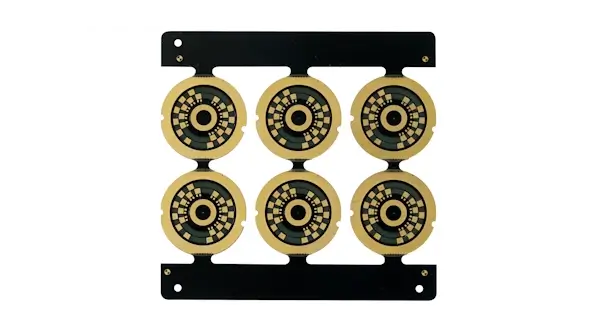

Heavy Copper PCB

PCBs with exceptionally thick copper layers, typically 3 oz or more, for high-current applications.

- Extremely high current-carrying capacity

- Enhanced thermal conductivity

- Ability to withstand repeated thermal cycling

- Reduced need for external heat sinks

Flexible PCB

Bendable PCBs made using polyimide or polyester substrates that can conform to dynamic or space-constrained designs.

- High flexibility and bendability (can flex over 200 million cycles)

- Lightweight and space-saving design

- Excellent vibration and shock resistance

- Can be single-layer, double-layer, or multi-layer

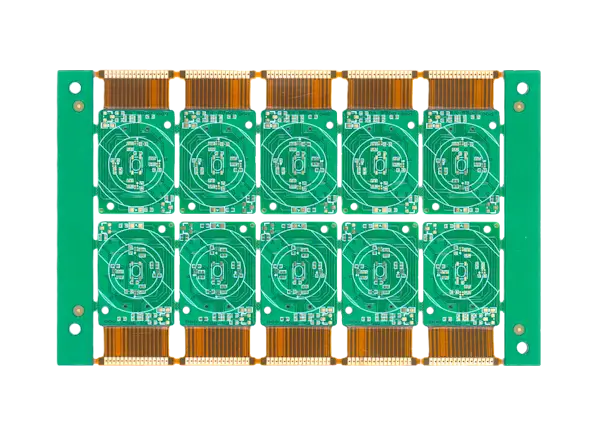

Rigid-Flex PCB

Hybrid circuit boards that combine rigid and flexible substrates into a single integrated assembly.

- Combines stability with flexibility

- Eliminates connectors and solder joints between rigid sections

- Increased reliability with fewer interconnection points

- Space and weight-saving

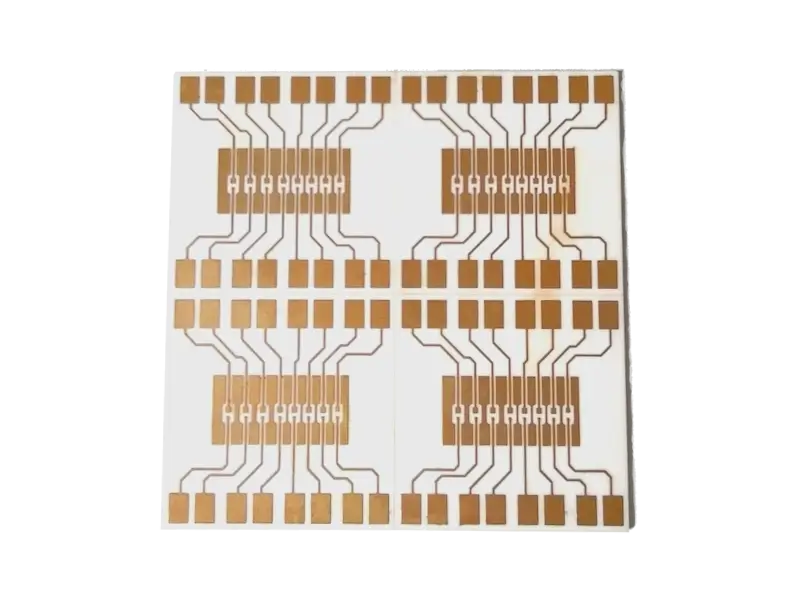

Ceramic PCB

Circuit boards manufactured using ceramic substrates like Al₂O₃ and AlN for extreme thermal and electrical performance.

- Excellent thermal conductivity

- High-temperature operation

- Superior electrical insulation and dielectric strength

- Low thermal expansion coefficient matching semiconductors