Arya Li, Project Manager at NextPCB.com

Support Team

Feedback:

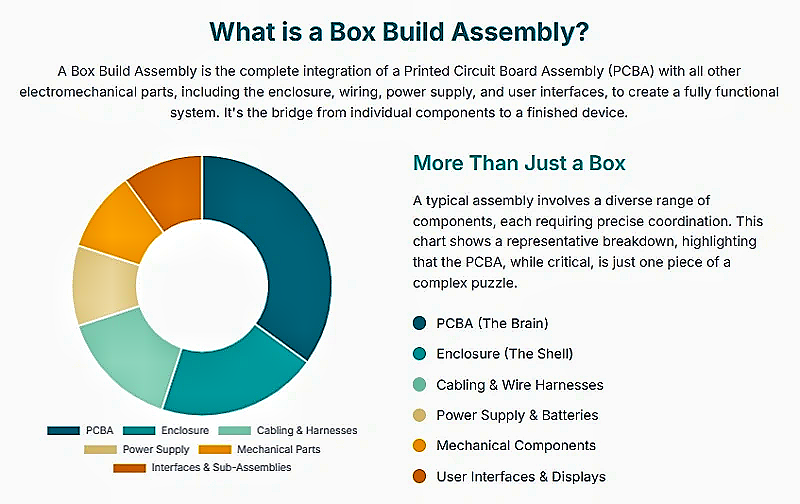

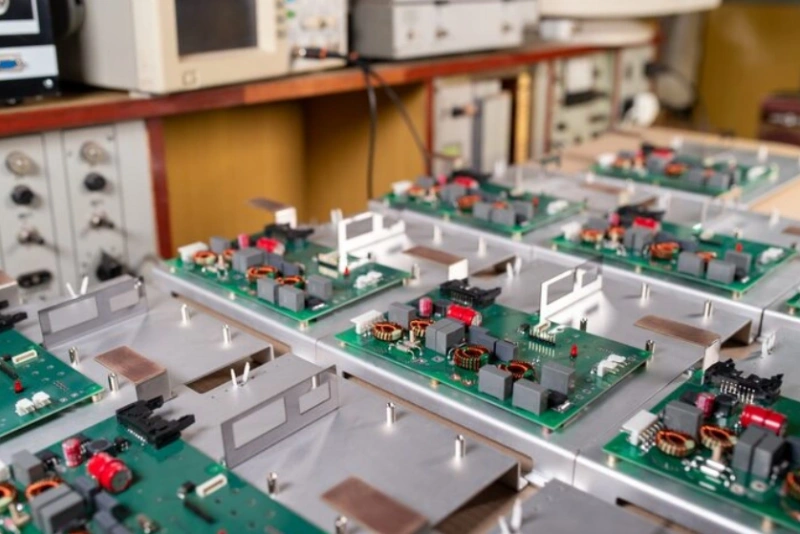

support@nextpcb.comThe realization of electronic products is typically divided into two main stages: circuit board level production and final system integration. The former involves Printed Circuit Board Assembly (PCBA), focusing on building the "brain" of the device. The latter, known as Box Build Assembly, is responsible for transforming functional circuit boards into a complete, ready-to-use product for the end-user. To understand what is box build assembly, one must first recognize its critical bridging role throughout the product lifecycle.

The core of Box Build Assembly lies in its holistic nature. It encompasses a complex series of steps, including mechanical assembly, electrical integration, cable routing, sub-assembly installation, firmware loading, and system-level functional testing, all completed within a specified chassis or enclosure. It extends the scope of electronics manufacturing from mere circuit boards to the final product form. The goal of this phase is to ensure that all components of the product—whether electronic components, mechanical structures, or user interfaces—work together seamlessly and perfectly.

The complexity and application range of these box build assemblies are vast. They can be as simple as mounting a single circuit board in a standard metal enclosure, or as complex as constructing a precision integrated system that includes multiple sub-assemblies, advanced thermal management solutions, embedded software, and intricate communication systems. As modern product design grows in complexity, incorporating multi-layered integration such as sensors, user interfaces, and complex wiring between multiple boards, the need for specialized management of this cross-disciplinary integration increases.

As the product transitions to the final assembly stage, ensuring that every connection, enclosure, and interface aligns precisely is crucial. If system integration is poorly managed, Original Equipment Manufacturers (OEMs) will face increased quality risks, reduced cost efficiency, and fragmented supplier management (known as "supplier sprawl"). Therefore, what is box build assembly is not just an extra step; it is a vital strategy for risk mitigation and quality control in modern complex hardware manufacturing.

Box Build Assembly's success hinges on the precise coordination and management of the diverse components that constitute the final product. These components include not only purely electronic parts but also critical mechanical and electromechanical elements.

Every efficient box build is composed of three core components:

In addition to core components, Box Build Assembly extensively integrates sub-assemblies to enhance functionality and enable connectivity:

It is noteworthy that the quality assurance structure for box build assembly is more complex than for mere PCBA. Traditional PCBA quality focuses on the IPC-A-610 standard (Acceptability of Electronic Assemblies), but a complete box build must extend its focus to cable standards (IPC/WHMA-A-620C) and enclosure standards (IPC-A-630). This requirement for three distinct specialized IPC standards means that effective Box Build Assembly necessitates a highly diversified set of professional skills and a robust Quality Assurance structure, clearly differentiating the professional domains between pure PCB/PCBA companies and providers offering comprehensive Electronic Manufacturing Services (EMS).

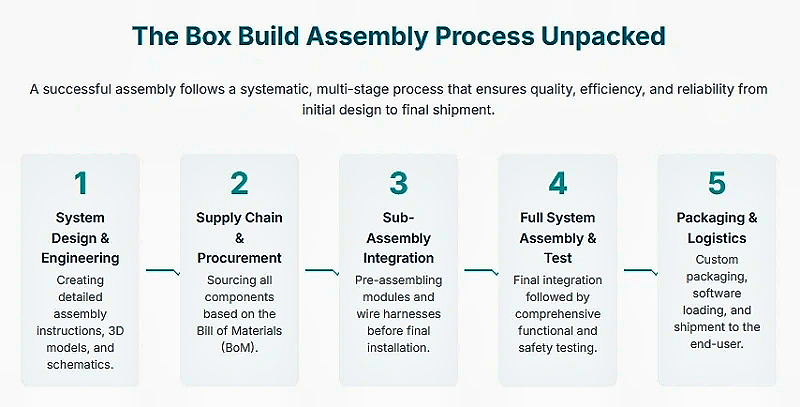

To understand how a design is transformed into a deployable product, one must detail the five key stages of the box build assembly process. The core document running throughout the entire process is the Bill of Materials (BoM), which is considered the "DNA" of the product, providing information and guidance for every phase of the project. A good, accurate BoM is the central tool for quality control, cost calculation, and cross-team communication.

>Recommend reading: HQ Online Free Bill of Materials (BOM) Parts Matching and BOM Checker Tool

The Box Build Assembly Process Unpacked

The box build assembly process typically includes the following five core stages:

Before initiating the project, the OEM must also clearly define regulatory compliance requirements (such as FCC, CE, RoHS, etc.), as these requirements will directly guide component selection and testing procedures within the box build assembly process.

It is important to emphasize that the quality of the provided documentation has a decisive impact on the efficiency of the entire process. Since experienced service providers already possess optimized workflows and mature supply chains, the accuracy and maturity of the BoM provided by the OEM are critical variables determining their ability to quickly optimize production flow and achieve a faster Time-to-Market (TTM). If the BoM is inaccurate, the procurement stage will be affected, leading to component shortages, which consequently causes severe delays during the system integration phase.

Therefore, an accurate BoM and detailed testing procedures are essential prerequisites for ensuring that outsourced box build assembly process remains streamlined and cost-effective.

Modern Electronic Manufacturing Service (EMS) suppliers have developed scaled solutions that go beyond basic component assembly (PCBA), focusing on providing comprehensive product realization services, which include complete system integration.

Box Build Assembly manufacturers differ from traditional circuit board manufacturers in their holistic approach to handling the entire system, ensuring all mechanical and electrical components work seamlessly together, mitigating the risks associated with 'supplier sprawl'. This holistic strategy is particularly beneficial for complex electronic devices that require various components to interact flawlessly for optimal performance.

OEMs choose to utilize pcb box build assembly services, precisely to consolidate complex mechanical, electrical, and testing requirements into one managed, traceable process. By doing so, manufacturers reduce "supplier sprawl"—the significant risks and delays that arise from managing multiple vendors for circuit boards, cables, enclosures, and integration.

The choice between Box Build Assembly and pure PCBA often depends on the complexity and scale of the system. For simple, less complex devices, PCBA may suffice. However, for precision, large-scale systems involving more functions and subsystems, the comprehensive system-level integration offered by Box Build Specialists is necessary. While PCBA is generally faster and more cost-effective for high-volume production of standardized components, Box Build Assembly requires more time and higher costs due to the additional steps involved in integrating mechanics and testing.

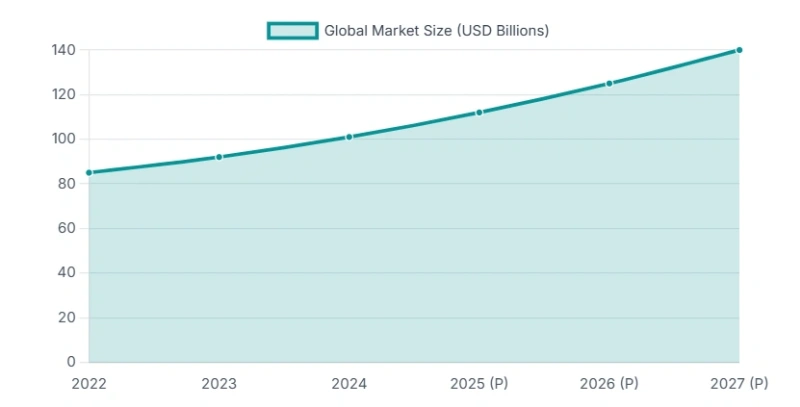

The growth of this service demand is closely related to the major trends in the electronics industry. The global PCBA market is projected to grow significantly, driven by demand in areas such as Industrial Internet of Things (IoT) and vehicle electrification. Every advanced PCBA used in these critical sectors (smart factories, electric vehicles) must ultimately be packaged, connected, and tested as a functional unit. Given that these are high-reliability, high-complexity applications, they demand a structured system integration solution, ensuring sustained high demand for box build assembly manufacturers. Therefore, understanding the strategic value of pcb box build assembly services is crucial for any OEM planning long-term product strategy.

Learn Turnkey PCBA Services at NextPCB Get PCB Assembly Quote Online

The table below summarizes the key differences in scope between PCBA and Box Build Assembly:

| Feature | Printed Circuit Board Assembly (PCBA) | Box Build Assembly |

|---|---|---|

| Primary Output | Fully assembled and tested functional circuit board. | Completed, deployable end-user-ready product. |

| Integration Focus | Component soldering (SMT/THT) and board-level integrity. | System integration (PCBA, mechanical, electrical, firmware). |

| Core Materials | Bare PCB, electronic components (ICs, resistors, capacitors, etc.). | PCBA, enclosure, power supply, cables, mechanical parts, UI components. |

| Key Standards | IPC-A-610 (Acceptability of Electronic Assemblies). | IPC-A-630 (Electronic Enclosures), IPC/WHMA-A-620C (Wire Harnesses), ISO, UL/CE. |

| Typical Testing | AOI, X-ray, In-Circuit Test (ICT), partial functional testing. | Functional Test (System-level), environmental testing, regulatory compliance verification. |

Box build assemblies are crucial in high-reliability fields such as medical devices, industrial control panels, aerospace, and communication systems. In this mission-critical hardware, any failure can have severe consequences, thus requiring box build printed circuit board assembly services to possess highly specialized mechanical, electrical, and functional integration capabilities.

To ensure the high quality of system integration, service providers must adhere to multiple professional standards that cover beyond the circuit board, such as IPC-A-610, IPC-A-630, and ISO 9001. Service providers must comply with multiple professional standards beyond the circuit board:

Top-tier box build printed circuit board assembly services must hold a substantial number of certifications to operate in high-risk markets. These certifications prove that the product has met necessary safety and performance standards, helping to build customer trust and ensure consistency in production:

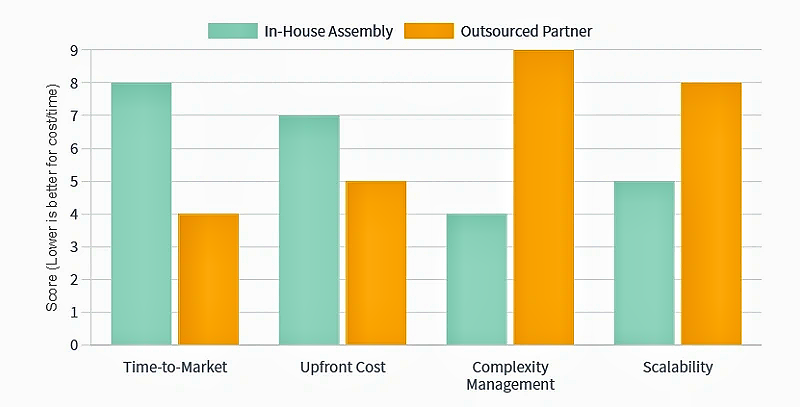

For Original Equipment Manufacturers (OEMs), outsourcing complex pcb box build assembly services to specialized Contract Manufacturers (CMs) is a critical strategic decision that offers multiple commercial and operational advantages.

The Strategic Advantage of Outsourcing

Outsourcing Box Build Assembly allows OEMs to avoid the significant Capital Expenditures (CAPEX) required for setting up an internal assembly line, which involves machinery, tooling, and specialized skilled labor. Contract Manufacturers leverage their inherent economies of scale and established supply chain relationships to procure components at lower costs, passing these savings on to the customer. By avoiding these upfront costs, businesses can reallocate internal resources to core value-creation activities such as Research and Development (R&D) and marketing.

Speed is paramount in the competitive electronics industry. Outsourcing system integration eliminates the long lead times caused by resource constraints or learning curves in internal development. Experienced pcb box build assembly services providers possess optimized workflows, streamlined assembly processes, and perfected vendor relationships, enabling them to efficiently handle large-volume production and deliver products on time. A faster Time-to-Market not only meets customer demands but also provides a crucial competitive advantage.

Market Landscape & Growth

One of the most significant benefits of outsourcing is the ability to rapidly adjust production scale based on market demand. Whether a small batch for prototyping or high-volume production is needed, outsourcing partners can flexibly adapt to the OEM's requirements. This flexibility allows businesses to quickly respond to changing market dynamics without overcommitting to capital expenditures or facing internal operational bottlenecks.

Outsourcing shifts the risks associated with in-house production (such as equipment failure, labor shortages, or quality issues) to the specialized partner. Trusted service providers have robust risk management practices and contingency plans in place to ensure uninterrupted production and minimize the likelihood of costly product recalls.

Outsourcing box build assemblies essentially transforms the manufacturing process from a high-risk operational burden (i.e., managing cross-disciplinary inventory, labor, and quality) into an scalable strategic asset. By reliably externalizing production at scale, the OEM's focus can shift from managing production logistics to pure product innovation and market penetration, thereby strengthening the company's overall strategic focus.

This article provided an in-depth analysis of what is box build assembly, confirming its role as the final, comprehensive stage in the electronics manufacturing process, responsible for integrating the functional PCBA with all necessary mechanical, electrical, and software components to create a market-ready product.

Successful electronic product realization relies on two critical links: a high-quality PCBA foundation, followed by robust system integration provided by specialized box build assembly manufacturers. As the demand for integrated, high-reliability products continues to grow in sectors like Industrial IoT and medical devices, the need for specialized capabilities in box build assemblies becomes increasingly important.

While next-generation PCBA manufacturing focuses on the foundational area of printed circuit board assembly, understanding the broader system integration ecosystem is vital for customer success. As technology advances, the automation and quality improvement of PCBA drive the increasing demand for complex, compliant Box Build Assembly integration. This not only solidifies its critical status in the product lifecycle but will also become an important trend in the future of electronics manufacturing.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now