Support Team

Feedback:

support@nextpcb.comNextPCB is fundamentally committed to providing a completely transparent pricing structure with no hidden costs. To continuously deliver high-quality products and outstanding service, NextPCB constantly optimizes production processes and actively introduces and refines advanced technologies. Simultaneously, we remain dedicated to fully meeting our customers' increasingly diverse design and manufacturing requirements.

No more waiting days for your PCB or PCBA quote. The traditional bottleneck is now history, thanks to NextPCB's Instant Online Quoting System! Simply upload your Gerber files( for PCBA Quote, BOM and a Coordinate File are additionally required) to receive immediate pricing and lead times. For complex projects requiring specialized manual review, we complete the final quote within hours, not days, ensuring you can accelerate your design and manufacturing timeline without unnecessary delays.

However, the design and manufacturing of PCBs is a highly complex engineering process. Behind every seemingly straightforward online quotation lies an extensive amount of rigorous engineering assessment work. This inherent complexity can lead to necessary price adjustments between the initial online quote and the final engineering review.

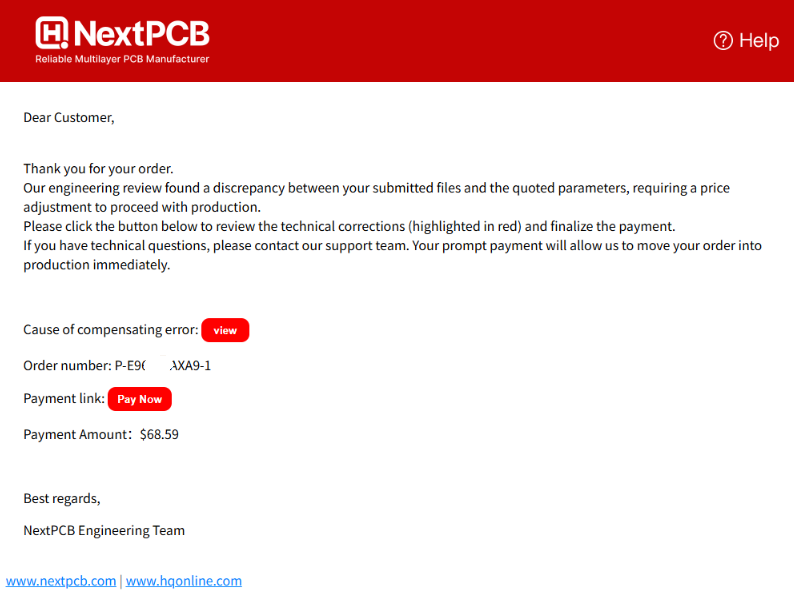

Some users encountered the following situation after placing an order through pcb online quotation system: clearly having completed payment according to the system quote, and full of anticipation for shipment, they instead received our email reminder—"Your order needs a supplementary price difference".

We completely understand your feelings at this moment. You might feel confused: "Why wasn't it calculated clearly at the start?" or concerned: "Are there hidden costs?"

As a PCB manufacturer dedicated to quality and transparency, NextPCB believes it is crucial to explain the logic behind these necessary price adjustments. This process is not about hidden fees; it's about our commitment to ensuring your boards are "built right the first time".

NextPCB's online quoting system provides a rapid cost estimate based on the Gerber files you upload and dozens of key parameters (such as dimensions, layers, and quantity). However, the infinite variations in PCB design mean that a standard algorithm cannot account for every unique circumstance.

Therefore, before formal production begins, our professional CAM Engineers conduct a precise Engineering Query (EQ) / DFM review to ensure manufacturability.

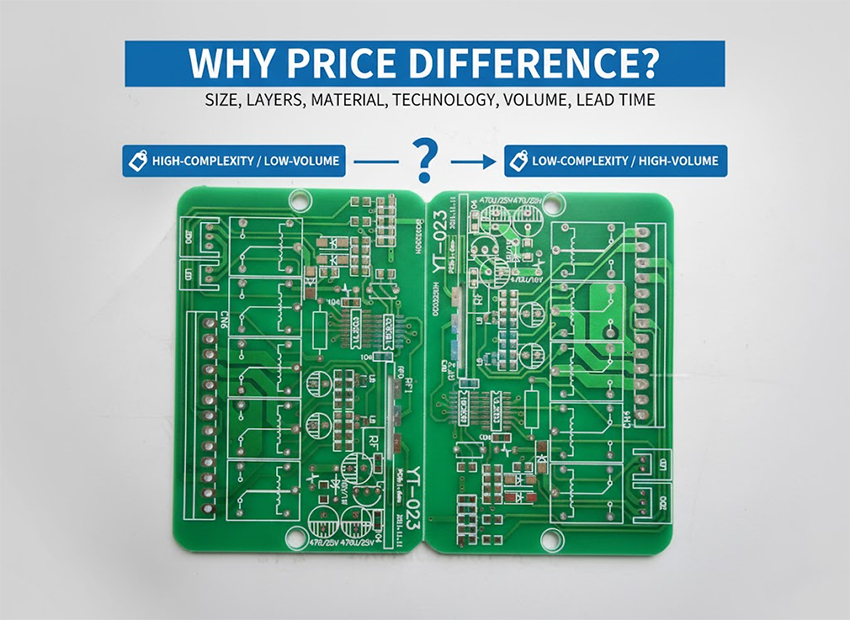

When using the online quotation system, many users default to selecting "Standard Process" for convenience. However, when our engineers open your Gerber files, they often discover more advanced design details:

![]()

Case Study: The "Trap" of Parameter Modification

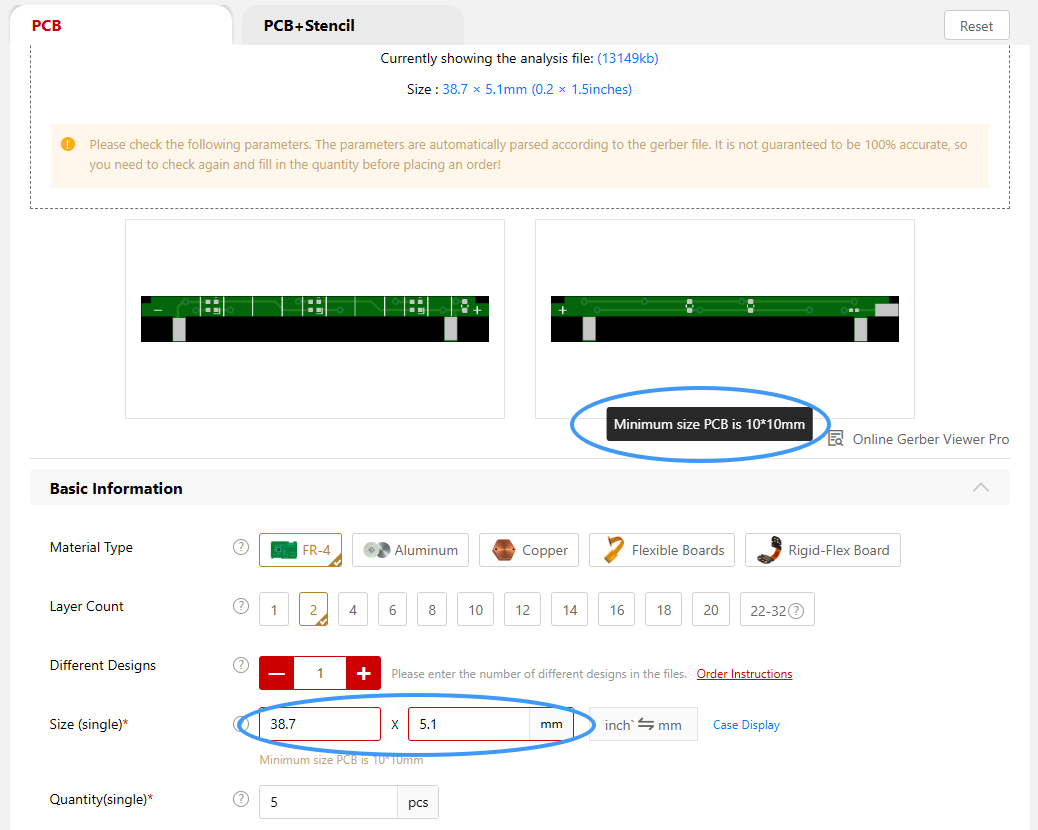

A customer attempting to order a small-sized PCB (38.7 x 5.1mm) encountered a system prompt stating that this size could not be directly ordered online. To proceed, they modified the input parameters to 38.7 x 10mm to successfully place the order.

However, the uploaded Gerber file reflected the actual, smaller size (38.7 x 5.1mm). Since the production of smaller PCBs often involves higher manufacturing difficulty and costs, the system automatically detected the discrepancy between the ordered parameters and the actual file dimensions, subsequently requesting an additional fee (increasing the price from $6 to $50).

This incident led to customer confusion regarding the accuracy of the initial quote. It illustrates that the online quotation system is primarily based on the input parameters, but the final price remains subject to the actual production complexity and process requirements determined by your design files (Gerber).

Pop-up reminder - Dimensions do not meet minimum requirements.

This area frequently represents the most overlooked hidden costs. NextPCB is dedicated to helping customers save expenses, but practical manufacturing limitations are sometimes unavoidable:

If your single Gerber file contains two or more independent, non-panelized circuit board designs, this requires additional Engineering Data Processing and setup time from our CAM team. Consequently, an extra design handling fee will be applied.

To ensure smooth CAM review and production processing when using a Multi-Design file structure, we strongly recommend consulting our detailed operational specification:

NextPCB Multi-Design Ordering Specification: Different PCB Designs in Gerber Files

Some process options are difficult to fully cover in an automated system and require manual identification:

The shipping fee calculated during the online checkout process is an initial estimate based on the parameters (dimensions, layer count, quantity) you provided.

In some cases, after the PCBs have completed production and are prepared for packaging, we may find that the actual product weight (or volumetric weight) significantly exceeds the initial estimate. This typically occurs because:

When the disparity between the quoted and actual shipping cost is substantial, we will need to notify you to cover the shipping cost difference to ensure timely dispatch.

To ensure a smoother ordering experience, the NextPCB team offers a few practical suggestions:

Rest assured, with the continuous enhancement of our automation and Gerber file parsing technology, the probability of a required price adjustment is extremely low(In most cases, it's less than 3%), provided your PCB is designed according to our manufacturing guidelines and the parameters you manually confirm match your Gerber file.

Furthermore, to ensure a smoother customer journey, NextPCB has established an internal tolerance threshold: For minor price differences caused by subtle process variations, we will absorb the small cost. An adjustment will only be requested from the user if the difference exceeds this predetermined threshold. Every aspect of our quotation is transparent, and every price adjustment is implemented to guarantee quality.

The email notification will detail the reason for the price adjustment

Thank you for choosing NextPCB. We look forward to transforming your top-tier design into a perfect, top-tier product.

Ready for your next project?

Get PCB Price Online Try Free DFM Tool

You may also be interest in....

> NextPCB Multi-Design Ordering Specification: Different PCB Designs in Gerber Files

> How NextPCB ensures your product quality: Four Core Test Reports

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now