Support Team

Feedback:

support@nextpcb.comAt NextPCB, we are dedicated to providing products and services of the highest caliber. We continuously optimize our manufacturing processes and refine our technology to meet the increasingly diverse and complex design requirements of our global customer base.

To ensure we deliver premium quality and maintain sustainable production capabilities, special processes and custom requirements may incur additional charges based on their complexity and resource demands.

While all standard pricing is calculated instantly using our online quoting tool based on your uploaded Gerber files and selected options, there are critical exceptions. For certain intricate designs, specific special processes, or if the correct options are not accurately selected at the time of order submission, surcharges may apply during the mandatory Design for Manufacturing (DFM) file review process.

Try best free online gerber viewer

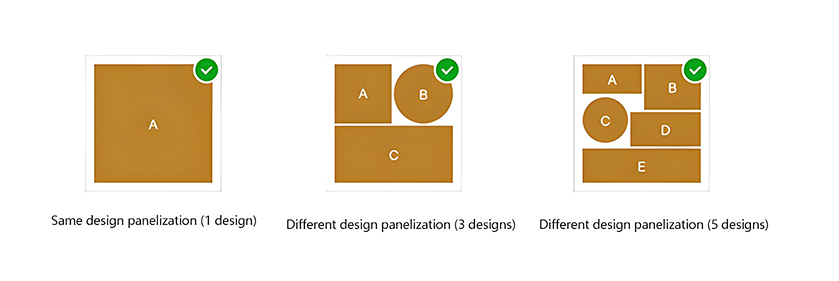

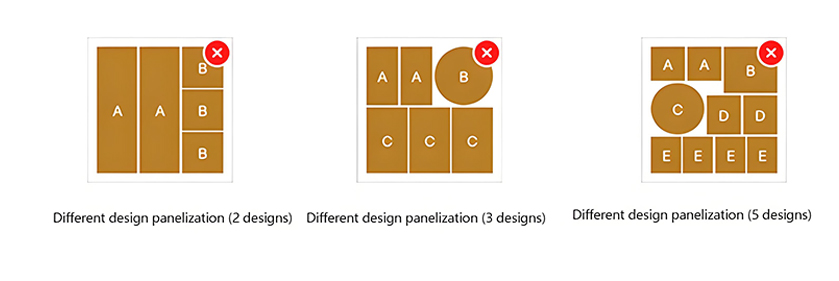

A Multi-Design File is defined as a single set of Gerber data that contains two or more independent and distinct circuit designs (e.g., Design A and Design B, not simply panelized copies of the same design).

If your submitted file contains multiple different designs, an additional design processing fee is required. This fee is calculated by selecting the corresponding number of different designs within the NextPCB online quotation calculator.

Note on SMT Assembly: If your order includes our SMT assembly service, any fees related to the PCBA Panelization (creating a manufacturing array for assembly) will be quoted separately from the PCB Multi-Design file handling fee.

To accurately select the corresponding number of designs and avoid delays, a "Different Design" is defined by the following criteria:

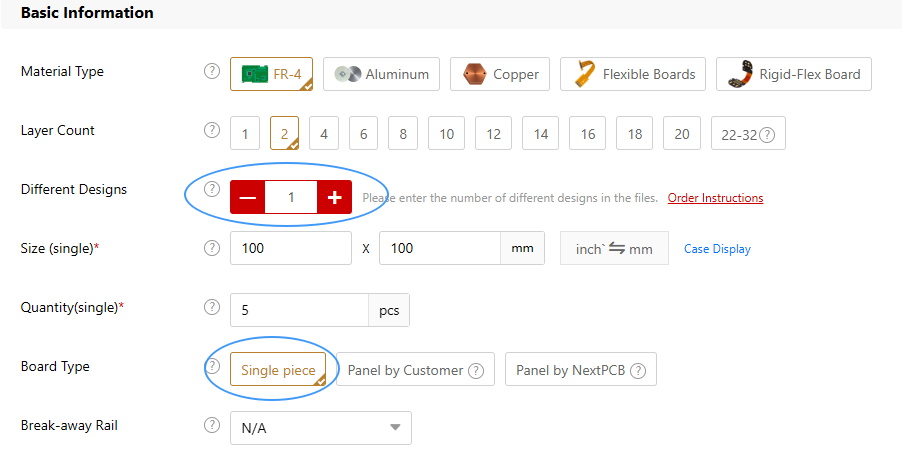

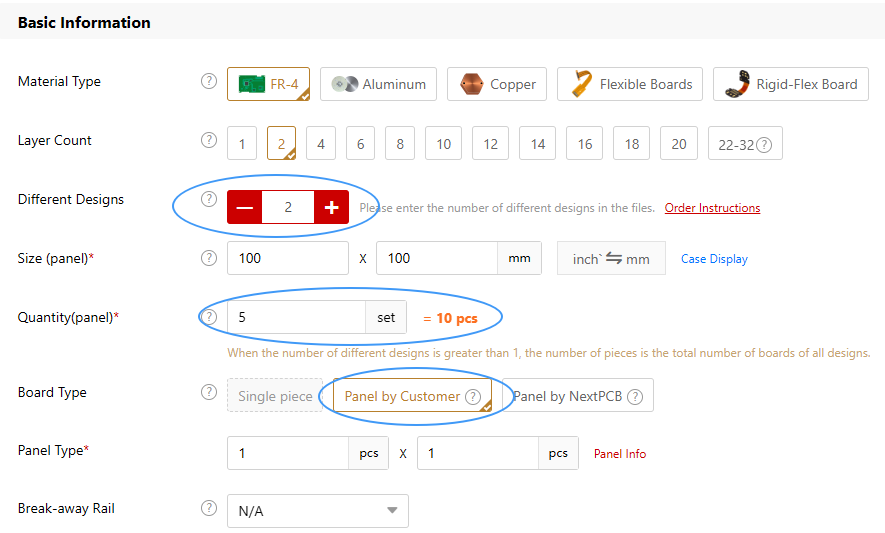

The default is a single design

Different Designs(2 designs): the value for quantity and board type have changed

For Multi-Design Orders, the method for calculating the final quantity of boards differs from standard single-design orders. We utilize the "Set" as the fundamental ordering unit to simplify complex orders.

The total number of individual circuit boards (Pieces) you receive is determined by the following formula:

Total Pieces = No. of Sets Ordered x No. of Different Designs x Panel Quantity per Design

Panel Quantity per Design: The number of copies of a single design that were grouped together in your panelization scheme (e.g., if you panelized a 1 x 3 array, the quantity is 3).

Example Calculation:

If your file contains 3 different designs (A, B, and C), and each design is panelized with 3 copies (1 x 3 array), and you select an order quantity of 10 Sets:

Total Pieces = 10 (Sets) x 3 (Designs) x 3 (Panel Copies) = 90 Pieces

This means you will receive 30 pieces of Design A, 30 pieces of Design B, and 30 pieces of Design C.

When placing an order for PCBA (Printed Circuit Board Assembly), the required quantity must always be input in Individual Pieces:

If there are multiple different designs, the files should be provided as follows:

To ensure a smooth, error-free production process, all Multi-Design files must meet the following consistency requirements:

Uniform Panelization is Required: All different circuit designs included within the same Multi-Design order must utilize a unified panel format and maintain consistent individual quantities.

We will not be held responsible for incorrect quantities in such cases:

NextPCB is committed to high-precision manufacturing. By following these Multi-Design ordering specifications, you help us streamline the DFM process and accelerate your project's time-to-market.

Get Your Price Online Check Gerber Files Free Try Our Free DFM Software

You may also be interest in....

> How NextPCB ensures your product quality: Four Core Test Reports

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now