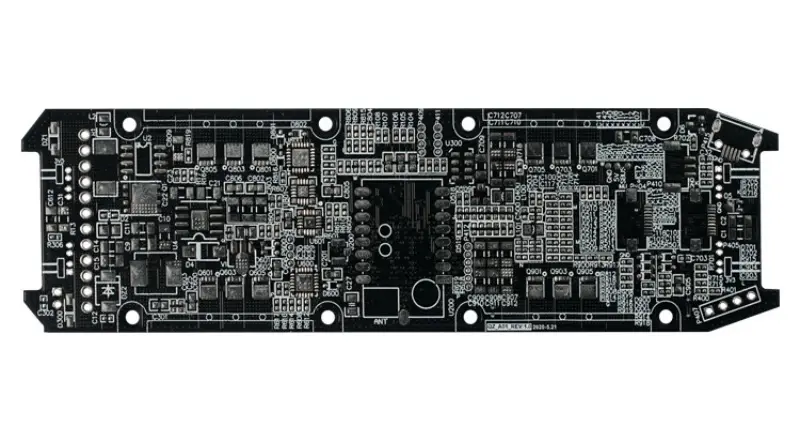

PCB for Internet of Things (IoT)The Internet of Things (IoT) is reshaping how we interact with the world, connecting everything from smart home thermostats to industrial sensors and medical wearables. At the heart of every successful IoT device lies a highly reliable, compact, and efficient Printed Circuit Board (PCB).

At NextPCB, we specialize in manufacturing high-performance PCBs that meet the unique demands of the IoT ecosystem. whether you are developing a sleek wearable device requiring Rigid-Flex technology or a robust industrial sensor needing high reliability, our fabrication and assembly services are optimized to accelerate your time-to-market.

1. Driving the Connected Future: Our IoT PCB Solutions

The IoT market is diverse, but the requirement for smaller, faster, and more energy-efficient electronics is universal. NextPCB supports a wide range of IoT sectors with tailored manufacturing solutions:

IoT Application Segments and PCB Solutions

| IoT Segment |

Typical Applications |

Key Requirements |

NextPCB Solution |

| Consumer Electronics & Wearables |

Smartwatches, TWS earbuds, fitness trackers |

Ultra-compact form factor, irregular shapes, mechanical durability |

Rigid-Flex PCBs and HDI (High Density Interconnect) technology enable intricate folding and 3D packaging without sacrificing signal integrity |

| Smart Home & Automation |

Smart lighting, security cameras, home automation devices |

Stable connectivity, cost efficiency, suitability for high-volume production |

Cost-efficient FR-4 multilayer boards with integrated antenna modules (Wi-Fi/Zigbee/Bluetooth) and reliable surface finishes such as ENIG |

| Industrial IoT (IIoT) |

Factory sensors, monitoring and control systems |

Resistance to vibration, heat, and moisture; reliable power and thermal management |

Wide range of copper thickness options for rigid boards (up to 6 oz, depending on design and process requirements), with thinner copper in flex areas (e.g., 1/3–1 oz) to optimize power distribution and thermal performance |

| Automotive V2X |

Vehicle-to-Everything communication modules |

Zero-defect manufacturing, automotive-grade quality requirements |

PCB manufacturing in strict accordance with IATF 16949 automotive quality standards |

2. Critical Design & Manufacturing Requirements for IoT PCBs

Developing a PCB for an IoT device presents unique challenges for both engineers and procurement managers. Here is how NextPCB’s technical capabilities address them:

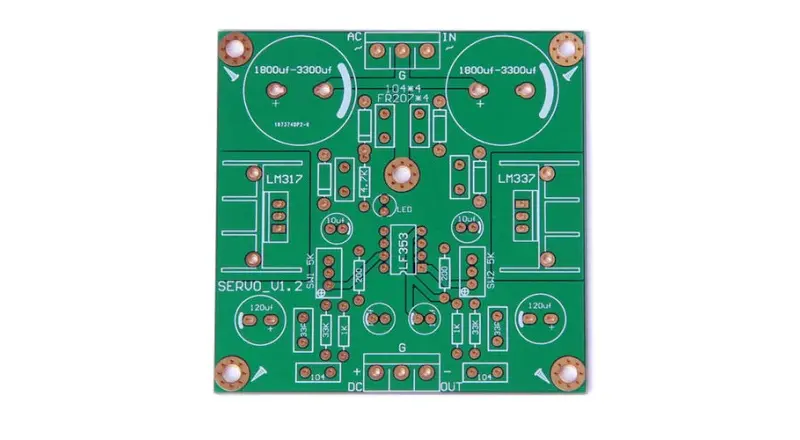

2.1. Size and Flexibility (Rigid-Flex Advantage)

As IoT devices shrink, standard rigid boards often fail to fit.

- Why it matters: Rigid-Flex PCBs eliminate bulky connectors and cables, reducing the device's weight and improving reliability (fewer solder joints to fail).

- NextPCB Capability: We manufacture Rigid-Flex boards (2-32 layers) with polyimide flex sections capable of withstanding dynamic bending. The minimum trace/space for flex areas can reach 2/2 mil, while the standard minimum for rigid areas is 3/3 mil (consult with our engineering team for specialized HDI or ultra-fine pitch requirements).

2.2. Connectivity & Signal Integrity

IoT is all about communication. Poor PCB layout or manufacturing tolerances can kill RF performance.

- Why it matters: 5G, GPS, and Bluetooth signals are sensitive to impedance mismatches.

- NextPCB Capability: NextPCB provides professional impedance control and testing. Our standard impedance tolerances are: ≤50 Ω: ±5% and >50 Ω: ±10%. For critical signal paths, tighter tolerances can be negotiated, supported by impedance coupons and TDR (Time Domain Reflectometry) verification to ensure your device stays connected flawlessly.

2.3. Power Efficiency

Battery life is a key selling point for IoT products.

Why it matters: Current leakage or inefficient power distribution can drain batteries prematurely.

NextPCB Capability: We assist in DFM (Design for Manufacturing) checks to optimize copper layout and suggest low-loss materials that extend battery life.

3. Why Choose NextPCB for Your IoT Projects?

For procurement managers and product engineers, we bridge the gap between complex designs and scalable manufacturing.

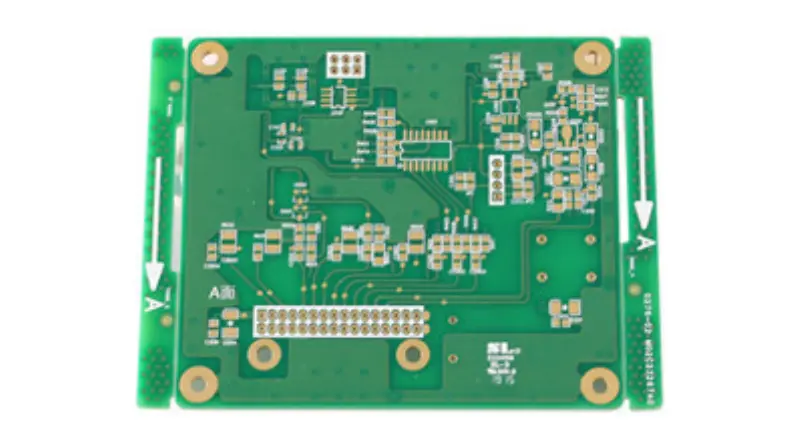

3.1. Advanced Manufacturing Capabilities

NextPCB supports materials ranging from standard FR-4 to high-frequency Rogers/PTFE. Our facilities are equipped to handle complex stack-ups:

- Layer Count: Up to 2-32 layers for rigid boards; 1-6 layers for flexible sections within rigid-flex structures.

- Precision: Standard minimum trace/space of 3/3 mil (rigid) and 2/2 mil (flex).

- Copper Weight: Options up to 6 oz for rigid areas to support high-power IoT applications.

3.2. Certified Quality Assurance

Reliability is non-negotiable. Our facilities hold the certifications global brands trust:

- ISO 9001:2015 (Quality Management)

- UL Certified (File No. E469747)

- IATF 16949 (Automotive Standard)

- ISO 13485 (Medical Devices)

- RoHS & REACH Compliant

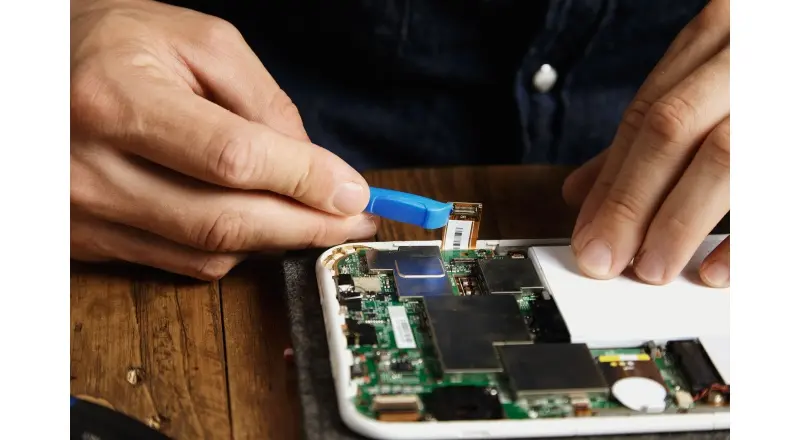

3.3. One-Stop Turnkey Services

Simplify your supply chain. NextPCB handle everything from PCB fabrication to component sourcing and assembly:

- Component Sourcing: Reliable procurement via authorized distributors (e.g., Digi-Key, Mouser, Arrow, etc.) to prevent counterfeit parts.

- Assembly & Testing: Full SMT/BGA assembly supported by rigorous testing, including AOI, ICT, FCT, and X-ray inspection.

>>> PCB Capabilities Supporting IoT Industry

Turnkey PCB Assembly

Complete PCB assembly and component sourcing services optimized for rapid IoT prototyping and reliable, cost-sensitive volume production.

View Assembly Services

4. FAQs

Q1: Why is Rigid-Flex preferred for IoT wearables over standard PCBs?

Rigid-flex boards allow the circuitry to fold and fit into the 3D casing of a wearable device while reducing weight and improving mechanical reliability by removing fragile connectors.

Q2: Can NextPCB assist with component sourcing for IoT chips?

Yes. Our Turnkey Assembly service includes a robust component sourcing process. We have established long-term cooperation with major authorized distributors, such as Digi-Key, Mouser, and Arrow, among others, to ensure component authenticity.

Q3: What data do I need to provide for an IoT PCB quote?

For fabrication, we need Gerber files (RS-274X). For assembly, please provide a Bill of Materials (BOM) and Pick & Place files. If you require impedance control, please specify your requirements for TDR testing.

Q4: Do you offer prototyping for IoT devices?

Yes, we offer rapid prototyping services. For standard 1–2 layer boards, we can achieve delivery as fast as 24 hours. For multilayer boards, HDI, or Rigid-Flex designs, the lead time will be determined based on technical evaluation and process complexity.

Related PCB Application Industries

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate