The intelligent security industry has evolved far beyond simple alarm systems. Today, it encompasses complex networks of IoT devices, high-definition video surveillance, biometric access controls, and integrated urban management systems ("Smart Cities"). As the boundaries between security technology and computing continue to converge, the electronics used in these systems are increasingly required to support high-speed data transmission, image processing, and long-term continuous operation. NextPCB provides PCB manufacturing and assembly services designed to support these requirements and help reduce operational and reliability risks in modern security applications.

>>> Get a Security PCB Quote >>> Download Certifications & Test Reports

The Evolution of Intelligent Security

Intelligent security refers to the informatization of safety services, image transmission, and data storage technologies. The popularization of the Internet of Things (IoT) has transformed traditional security protection into integrated urban systems.

Modern security applications now take into account:

- Overall City Management: Comprehensive monitoring for public safety.

- Traffic Systems: The Internet of Vehicles enables faster tracking, accident handling, and theft prevention.

- Environmental Monitoring: Sensors for gas leaks, smoke detection, and weather conditions.

- Emergency Command: Integrated systems for rapid response coordination.

Critical Challenges in Security Electronics

Security devices often operate in challenging environments where failure is not an option. PCBs for this industry must overcome specific hurdles:

- 24/7 Continuous Operation: Surveillance systems and servers run non-stop, requiring PCBs with excellent thermal management and durability.

- Harsh Outdoor Conditions: Cameras and sensors exposed to rain, humidity, and temperature extremes need robust surface finishes and potential conformal coating.

- Signal Integrity: High-definition (HD) and 4K video transmission require impedance-controlled boards to prevent data loss or image artifacts.

- Miniaturization: Smart locks and wearable security devices demand high-density interconnect (HDI) designs to fit compact form factors.

Products and Applications of Security PCBs

NextPCB supports a wide range of intelligent security products across various sectors:

1. Common Smart Security Products

- Surveillance: Smart cameras (IP cameras), Infrared electronic walls, NVR/DVR hosts.

- Smart Home & Access: Smart locks, wireless door sensors, video doorbells, anti-theft integrated gateways.

- Environmental Safety: Smoke alarms, gas sensors, remote wind/rain sensors, gas leak disposal manipulators.

- Perimeter Defense: Infrared sensor alarms, electronic curtains, wireless motion detectors.

2. Key Application Sectors

- Urban Smart Security: Public space monitoring and traffic light control systems.

- Financial Security: ATM monitoring and bank vault access control systems.

- Campus & Park Security: Integrated monitoring for schools, universities, and industrial parks.

- Exhibition & Public Venues: Crowd monitoring and emergency exit control systems.

Building the next generation of smart security devices?

Why Choose NextPCB for Security Projects

NextPCB provides PCB manufacturing and assembly services tailored for security applications, with process controls and material options selected to support durability and stable performance under demanding environmental conditions.

- Certified Reliability: Certified Reliability: NextPCB operates under an ISO 9001-certified quality management system, with production processes aligned to UL, RoHS, and REACH requirements. Certification documents and compliance records are available for customer verification.

- One-Stop Solution: We offer a turnkey service including PCB manufacturing, PCB assembly, component sourcing, and final global shipping.

- Cost & Time Efficiency: Our integrated supply chain reduces your costs and saves time by eliminating the need to manage multiple vendors.

- Advanced Capabilities: From metal-core PCBs for heat dissipation in LED floodlights to high-frequency boards for radar sensors.

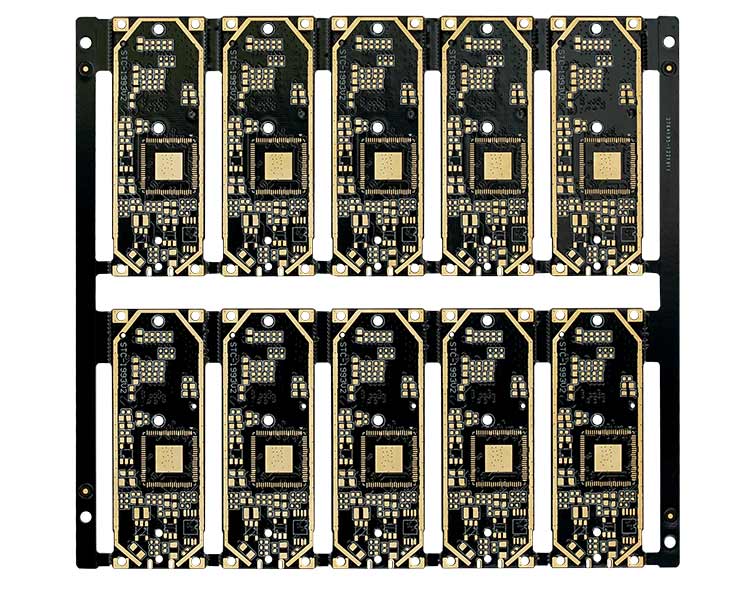

Security Industry PCB Capabilities

| Feature |

NextPCB Security Specification |

| Reliability Standards |

IPC Class 2 (default) / Class 3 available on request |

| Copper Weight |

Up to 10oz (supports heavy-copper designs for power distribution) |

| HDI Technology |

HDI Class I / II / III (1+N+1, 2+N+2, 3+N+3 laser drilling) |

| Assembly Testing |

X-Ray, AOI, ICT / Flying Probe, Functional Testing |

>>> Capabilities Supporting Security Tech

Turnkey PCB Assembly

Complete sourcing and assembly for cameras, sensors, and control panels.

Explore Assembly

Advanced Materials

High-Tg and Metal Core options for heat resistance and durability.

View Materials

Engineer's Reference: Material & Process Recommendations

| Product Category |

Recommended Material |

Recommended Finish |

Typical Engineering Tests |

| Outdoor IP Cameras |

High-Tg FR4 / Metal Core (MCPCB) |

ENIG / OSP |

Thermal cycling, moisture resistance |

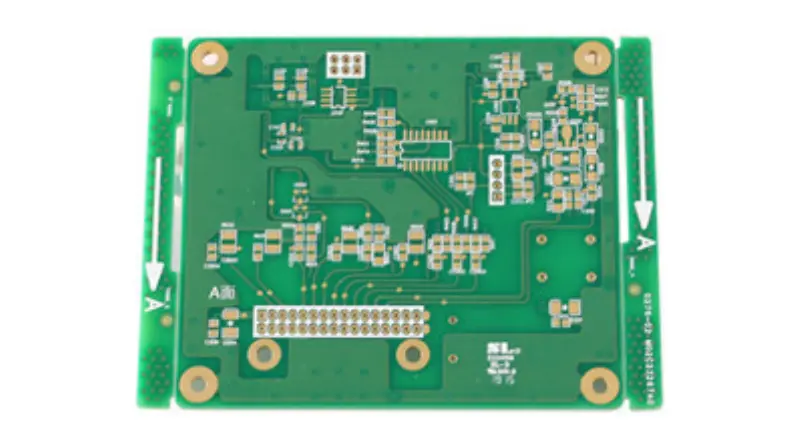

| Smart Locks & Sensors |

Standard FR4 / Rigid-Flex |

HASL (Lead-Free) |

Mechanical endurance testing |

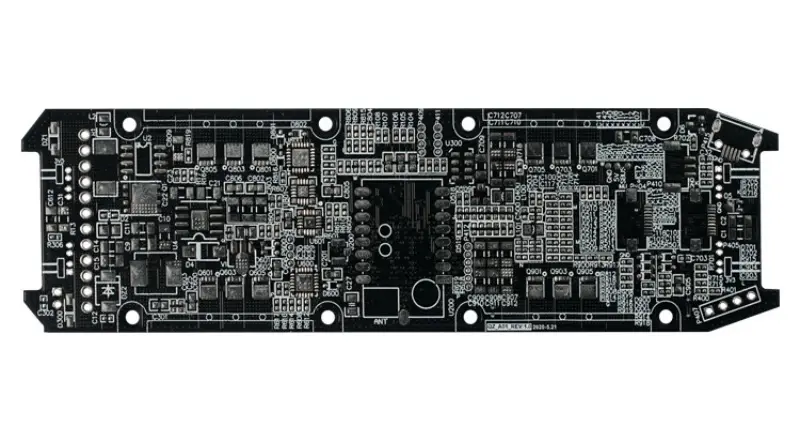

| NVR / DVR Control Hubs |

Multi-layer FR4 (High-Speed) |

Immersion Silver |

Impedance control, AOI inspection |

| Radar / Proximity Sensors |

Rogers / High-Frequency Laminates |

Immersion Gold / Hard Gold |

Dielectric constant & RF performance testing |

Frequently Asked Questions

What types of PCBs are best for outdoor security cameras?

For outdoor applications, we recommend High-Tg FR4 boards with ENIG surface finish and protective conformal coating to resist moisture, temperature fluctuations, and corrosion.

Do you support high-volume production for smart home devices?

Yes. NextPCB operates large-scale fabrication facilities capable of supporting high-volume production for consumer security products like smart locks and video doorbells.

Can NextPCB assist with component sourcing for security systems?

Yes. Our turnkey service includes sourcing reliable components from authorized distributors, ensuring the authenticity and quality of critical parts like sensors and microcontrollers.

Secure Your Electronics with NextPCB

In the security industry, hardware reliability plays a critical role in maintaining system stability and operational continuity, particularly in applications involving public safety and asset protection. Partner with NextPCB to ensure your security solutions are built on a foundation of quality and reliability. From prototyping to mass production, we are your trusted manufacturing partner.

>>> Upload Your Security PCB Design Now

Related PCB Application Industries

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate