Support Team

Feedback:

support@nextpcb.comTable of Contents

Introduction

In electronics manufacturing, even the most advanced PCB design cannot move forward without one critical step. This step is called component sourcing. It is the process of identifying, selecting, purchasing, and managing all the electronic components needed to build a functional printed circuit board. On paper, it sounds simple. Order the parts, wait for shipping, and start assembly. But in reality, component sourcing is one of the most complex, time-sensitive, and risk-prone stages of hardware production. Component sourcing matters because it directly affects cost, quality, and time-to-market. According to a 2023 report, 43% of enterprises reported experiencing project delays due to sourcing obsolete parts, with an average cost of $500,000 per incident.

Imagine a team building a prototype for an IoT environmental sensor. The PCB design is ready, the fabrication house is on standby, and the assembly schedule is locked in. But once they begin sourcing components, they discover that the chosen temperature sensor is out of stock worldwide, with a lead time of 14–26 weeks—a common occurrence during global supply fluctuations. Even a simple missing part, such as a 10 µF MLCC capacitor, can halt the entire production run. Engineers are then forced to redesign the circuit, find alternatives, or pay 5–10× inflated market prices, delaying launch and increasing development costs.

This is why modern PCBA providers like NextPCB and procurement platforms like HQOnline place significant emphasis on smart, reliable component sourcing. Ensuring that all components are available, authentic, cost-efficient, and delivered on time is essential for turning a great design into a manufacturable product—whether for a one-off prototype or mass-production build. Read on to understand better.

Component sourcing is the structured process of sourcing, evaluating, purchasing, and managing all electronic components required to assemble a printed circuit board (PCB). It ensures that every component listed in the Bill of Materials (BOM)—from microcontrollers to tiny 0201 resistors—is available, authentic, and compatible with the design before assembly begins.

In electronics manufacturing, component sourcing is not an optional task; it is a mission-critical step that determines whether a PCB can be produced at all. PCBA production delays are most often triggered by component shortages rather than PCB fabrication issues. Even a perfectly engineered board cannot enter assembly if a single required part is unavailable. When a critical component goes out of stock, it can halt assembly entirely and force engineers to search for alternatives or redesign the circuit. Shortages also drive up prices, increasing the overall manufacturing cost. These disruptions can push product launch timelines back by weeks or even months.

Component sourcing isn't just a purchasing task. It is one of the biggest determinants of product cost, quality, and production reliability. In fact, industry benchmarks show that electronic components typically account for 60–80% of the total cost of a PCBA, making sourcing decisions more financially impactful than PCB fabrication and assembly combined.

But beyond cost, sourcing directly affects lead time, manufacturability, yield, and even long-term product lifecycle stability.

The Bill of Materials (BOM) is where most PCBA expenses live. The price of a microcontroller jumping from $2.10 to $6.80 due to supply constraints can instantly destroy margins. Engineers often underestimate how volatile the component market is—IC prices can fluctuate as much as 30–200% during shortages.

In 2021-2022, lead times for automotive-grade MCUs reached 52+ weeks, pushing some manufacturers to redesign entire boards just to swap a single chip. Companies with flexible sourcing partners survived; others paused production.

NextPCB provides BOM cost analysis and multi-source lookup (Mouser, Digi-Key, LCSC, and OEM suppliers), helping engineers identify cheaper, drop-in-compatible parts without sacrificing quality.

Component shortages, factory shutdowns, end-of-life notices (EOL), and shipping delays can all derail a PCB production timeline. A single unavailable connector can delay mass production for weeks or even months. Imagine A client was prepared for a 10,000-unit production run but hit a roadblock—they couldn't source a simple 0.1-inch header. The lead time was an unbelievable 18 weeks. Once that single header was replaced with an available alternative, the entire project moved forward immediately. This is why NextPCB's sourcing team checks component availability right from the quotation stage, preventing costly surprises and delays before assembly begins.

Counterfeit components are a real and growing problem. Industry reports estimate that 1 in 10 electronic components circulating globally may be counterfeit, especially power MOSFETs, memory ICs, and analog chips.

Poor component sourcing increases risks such as:

NextPCB partners only with authorized distributors and trusted OEM suppliers, performing QC checks before components enter the assembly line.

Even a perfectly functional component can cause problems if it isn’t mechanically or electrically compatible with the PCB:

NextPCB engineers verify footprint and package compatibility before assembly, to avoid expensive post-production fixes.

A product may be in the market for years, but components often go EOL within 3–5 years. Without smart sourcing, companies face:

This is why many engineers prefer to use a centralized ecosystem like NextPCB, where components can be sourced, verified, and delivered directly to the assembly line—eliminating the risk of mismatched suppliers, wrong packaging, or slow international shipping. NextPCB provides lifecycle analysis and suggests alternatives with longer availability, reducing long-term risk.

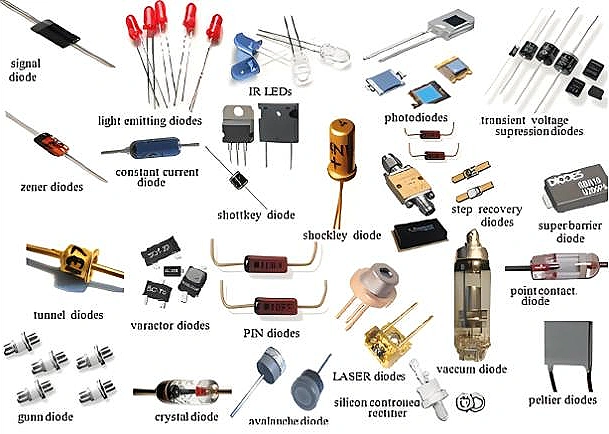

PCB component sourcing covers all parts mounted on or used with the PCB. Below is a clear breakdown:

These are the “brains” of the board—microcontrollers, memory, power ICs, wireless chips, and sensors. ICs are typically the most constrained parts during shortages. The scarcity of Integrated Circuits (ICs) is the most critical systemic risk in PCBA projects, often triggering costly project escalations. IC shortages lead to extreme lead-time extensions, sharp component price increases, and forced, time-consuming redesigns. Both academic studies and industry analyses show that this vulnerability in IC availability exposes the entire electronics value chain to major financial strain and severe schedule disruptions.

Passive components—such as resistors, capacitors, inductors, ferrite beads, and crystals—are inexpensive but dominate the component count on most boards. They make up the highest-volume category in any PCBA. For example, a typical smartphone PCB contains between 600 and over 1,000 passive components alone. For a better understanding, here are some of the most commonly used components found on a PCB.

Most modern PCBs depend heavily on SMD parts—from tiny 0201 resistors to larger QFN and BGA IC packages. Sourcing SMD components requires strict precision because package size, tolerance, and footprint must match exactly. Even a small mismatch, such as selecting a 0603 part instead of an 0805, can lead to assembly defects or mounting failures. Understanding PCB SMD component types and how to identify them is essential for accurate sourcing and reliable assembly.

Heatsinks, RF shields, switches, spacers, buttons, thermal pads, and power jacks all fall into this category. While they may seem secondary to the electronics, these components play a major role in manufacturability, mechanical stability, and assembly orientation. Selecting and sourcing the correct variant is critical, as even small differences in size, mounting style, or material can disrupt the entire assembly process.

> Recommend reading: Common Components on a PCBA and What Matters in Assembly

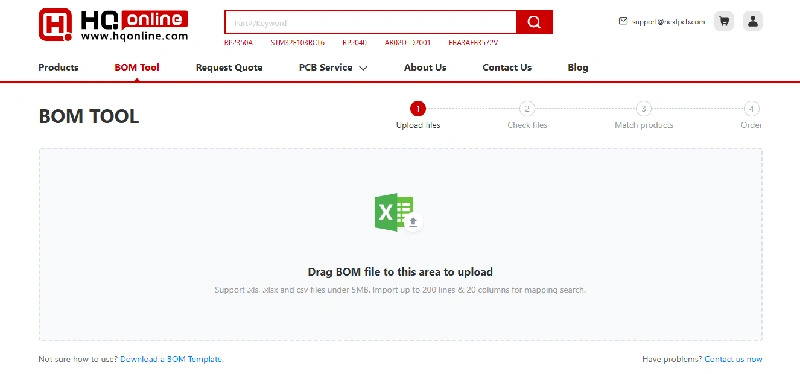

The component sourcing process begins with creating and verifying a complete, accurate Bill of Materials (BOM), which directly affects procurement speed and production readiness. A clean BOM, with correct part numbers, values, footprints, quantities, and approved alternatives, can reduce sourcing delays by up to 35%. Once the BOM is validated, sourcing teams search global supplier networks, including major distributors, Asian markets, OEM channels, and specialized vendors, to protect against shortages and price spikes. Availability and lead-time checks follow, ensuring every item is in stock or has a viable replacement.

With availability confirmed, pricing comparisons are conducted across regions, distributors, and packaging types, as component costs can swing dramatically based on demand and minimum order quantities. Authenticity and quality control are equally critical, as counterfeit components—estimated to make up 8–15% of the global market—pose major reliability and safety risks, requiring inspections, electrical tests, and verification steps before assembly. Finally, logistics teams consolidate shipments, manage customs documentation, and maintain proper storage conditions, as poor coordination alone can add several days to the lead time. This entire workflow is the standard sourcing process used by electronics manufacturers—and the same process NextPCB and HQOnline streamline for engineers to ensure smooth, disruption-free production.

Component sourcing in 2025 is marked by persistent volatility, even as the global supply chain continues to recover from earlier disruptions. Engineers face unpredictable lead times, fluctuating prices, and rapid shifts in component availability, particularly in microcontrollers, power management ICs, memory chips, and automotive-grade parts. These challenges are amplified by frequent lifecycle changes, with components going EOL faster than before due to new process nodes, restructuring among semiconductor manufacturers, and evolving standards. Meanwhile, BOMs are growing more complex, creating pressure on engineering teams who already need to balance performance, cost, reliability, and compliance in a single design cycle. All of these variables make sourcing an increasingly strategic function rather than a simple procurement step.

The global supplier landscape is becoming more fragmented, intensifying the difficulty of finding reliable sources. Engineers must navigate authorized distributors, independent vendors, regional suppliers, manufacturer-direct channels, and online marketplaces—each with different levels of transparency and risk. This fragmentation increases the chances of counterfeit or grey-market components entering the supply chain, which can lead to catastrophic failures, costly recalls, or field defects. The combination of market volatility, fragmented sourcing, and authenticity concerns creates a challenging environment that demands better tools, smarter workflows, and deeper supply-chain awareness from engineering teams.

Adopting supply-chain-aware design practices has become essential for modern hardware teams. Engineers should analyze availability, lifecycle status, and multi-source options early in the design phase rather than waiting until production. This reduces the risk of late-stage redesigns and prevents project delays caused by last-minute shortages. Using digital tools to automate BOM analysis, cross-referencing, and pricing comparison also helps engineers optimize designs faster. Practices such as selecting mature, widely available packages, identifying alternative suppliers, and prioritizing components with stable lifecycles improve resilience and predictability. Consolidating procurement with integrated partners further streamlines timelines by coordinating sourcing, fabrication, and assembly within one workflow.

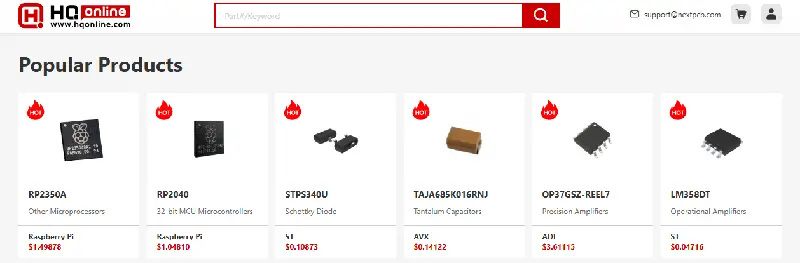

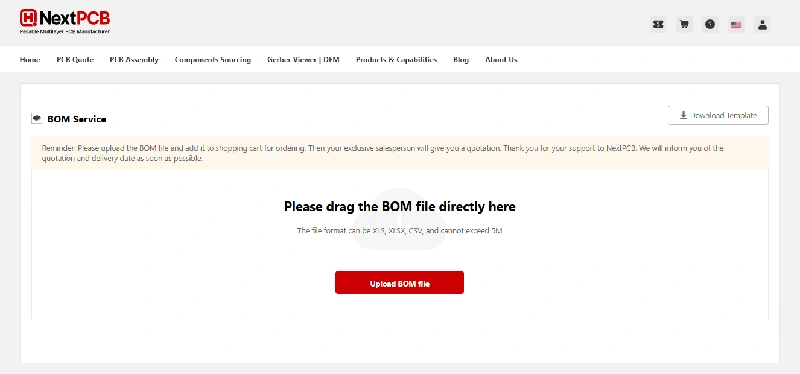

This is where NextPCB provides a strong advantage. Through HQOnline, engineers can upload their BOM and receive instant visibility into pricing, availability, lead times, lifecycle status, and cross-reference options across multiple distributors simultaneously. NextPCB's integrated supply chain, combined with its PCB fabrication and assembly services, minimizes delays and eliminates the typical friction between sourcing and production. Their rigorous supplier vetting process helps prevent counterfeit components from entering your product, while their engineering support team assists with BOM reviews, alternate recommendations, and manufacturability insights. By combining best practices with a partner like NextPCB, hardware teams strengthen supply-chain resilience, reduce overall project risk, and accelerate time-to-market with confidence.

As electronics continue to evolve, smaller footprints, higher integration, and tighter tolerances, the complexity of component sourcing will only grow. Global supply chains are entering an era defined by unpredictable lead times, rapid EOL cycles, geopolitical pressure, and volatile demand. Tomorrow's PCB designers and manufacturers won't just need to pick the right components; they'll need real-time visibility, predictive sourcing, lifecycle intelligence, and a partner capable of navigating an increasingly fragmented supplier ecosystem.

This future is already taking shape. Sourcing constraints will continue to be the dominant and most critical bottleneck for PCBA production timelines well into the foreseeable future—likely through the end of the decade. The challenge is evolving from broad, industry-wide shortages to more targeted disruptions driven by specialized materials, advanced semiconductor dependencies, and escalating geopolitical risks. The winners in this landscape will not be the teams with the most innovative designs. They will be the teams with the most resilient sourcing pipelines.

NextPCB has built an integrated manufacturing ecosystem designed for the realities of present-day sourcing and the turbulence ahead. By merging component procurement, engineering verification, lifecycle insight, fabrication, and assembly into a single, synchronized workflow, NextPCB eliminates the hand-offs, blind spots, and delays that slow traditional production. HQOnline adds the intelligence layer that modern sourcing demands: real-time pricing, global availability checks, cross-reference options, supplier transparency, and lifecycle predictions, all available the moment you upload your BOM. As supply chains become more volatile, these capabilities won't be “nice to have”—they will be essential infrastructure for any serious hardware team.

You May also Need NextPCB's Full BOM Service

In a future where sourcing challenges will only intensify, NextPCB stands out as the partner engineered for stability, speed, and long-term resilience. Whether you're prototyping a new idea or scaling to mass production, the pathway is the same: smarter sourcing, safer components, faster builds, and stronger products. If you're ready to build hardware without the bottlenecks, friction, or uncertainty, the next step is simple—and it starts now. Upload your BOM online to get instant, real-time component pricing, and combine sourcing and assembly with NextPCB for the fastest, most reliable production experience.

About the Author

Abiola Ayodele: Broadcast Journalist & Tech Writer; Cooperate writer of NextPCB.

Specialize in technical writing, and editing, particularly in the areas of PCB design, semiconductors, cybersecurity, and emerging engineering technologies.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now