> Pro tip: Before manufacturing, upload your Gerbers to the free HQDFM Gerber Viewer to catch manufacturability issues early.

> or Learn Practical DFM Checklist and HQDFM Practice.

Support Team

Feedback:

support@nextpcb.comIntroduction

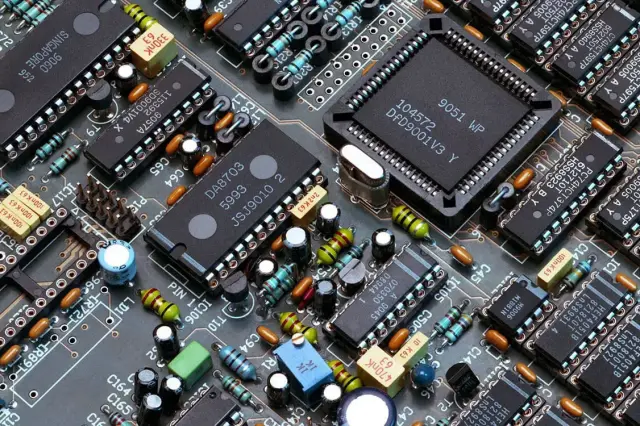

Circuit board components are essential components in a wide range of electronic devices, from smartphones and laptops to cars and airplanes.

A circuit board is a board with small electronic parts, like resistors, capacitors, diodes, and transistors. It's also called a printed circuit board (PCB). Special paths connect these parts to conduct and control the flow of electricity in a device.

This article aims to give you a complete overview of circuit board parts, what they do, and why they matter in today's electronics. You will learn about the various types of parts used in circuit boards, how to select them, and the process of manufacturing and testing them for quality by the time you finish reading.

Table of Contents:

> Pro tip: Before manufacturing, upload your Gerbers to the free HQDFM Gerber Viewer to catch manufacturability issues early.

> or Learn Practical DFM Checklist and HQDFM Practice.

Circuit board components (often called circuit board electronic components or electronic components PCB) are the physical devices soldered onto a printed circuit board to realize a circuit's function—resistors, capacitors, ICs, connectors, sensors, protection parts, etc. They sit on top of the components of PCB itself—laminate, copper, solder mask, silkscreen, vias, and finish—which enable assembly and reliability. For a refresher on PCB basics (layers, classes, artwork), see Printed Circuit Board Basics: From Design to Final Artwork.

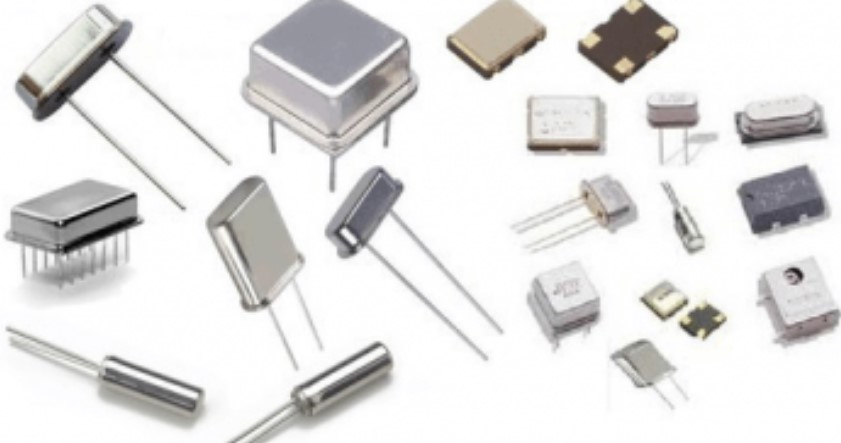

When people ask about circuit board components or a PCB parts list, they mean the placed devices used in PCBA—not the board materials. For clear printed circuit board component identification, we group everything into seven practical categories: Passives (R, C, L, FB, Y/X, T), Semiconductors (D, Q, U/IC), RF & Antenna (filters/baluns/couplers/antennas), Interconnect & Electromechanical (J/P, SW, K, M), Protection (F, TVS/MOV/GDT), Sensors & Transducers (varied refdes), and Board (host only)—stack-up, copper, vias, solder mask, silkscreen, and finish that host but aren't counted as components. Use silkscreen reference designators (e.g., R5, C12, U3, J1) to map each item in your electronic components PCB list to its role, keeping your components of PCB overview concise and easy to audit and manufacture.

(Click the "▶" to expand the PCB component types list.)

A labeled circuit board uses silkscreen and reference designators to guide placement, test, and troubleshooting:

Find the refdes (e.g., R45, C12, U8). The letter hints at the category; the number is unique per board.

Check polarity/orientation:

Match footprint & value: compare silkscreen and pad size with your BOM line (value, package).

Verify side & rotation using the Centroid (Pick-and-Place) file; it encodes refdes, X/Y, side, and rotation that the factory uses.

Quick reference: circuit board component identifiers (common):

R (resistor), C (capacitor), L (inductor), FB (ferrite bead), D/LED/TVS (diode), Q (transistor/MOSFET), U/IC (integrated circuit), Y/X (crystal/resonator), J/P (connector), F (fuse), SW (switch), K (relay), TP (test point), T (transformer), M (motor/fan), VR (variable resistor/pot).

Use this electronic parts identification flow when you're staring at an unknown board:

|

RefDes |

Qty |

Value / Rating |

Mfr |

MPN |

Package |

Footprint |

Description |

Notes |

Alt MPN |

|

R1 |

1 |

10 kΩ 1% |

Yageo |

RC0603FR-0710KL |

0603 |

R_0603 |

Pull-up |

– |

RC0603FR-1010KL |

|

C5 |

1 |

1 µF 25 V X7R |

Murata |

GRM188R71E105KA12 |

0603 |

C_0603 |

Decoupling |

– |

CL10A105KA8NNNC |

|

U1 |

1 |

MCU 32-bit |

ST |

STM32G0B1KET6 |

LQFP-64 |

LQFP64_10x10 |

Main controller |

Pin-1 dot |

ATSAMD21G18A-AU |

|

D3 |

1 |

TVS 5 V |

Littelfuse |

SP0503BAHTG |

SOT-23 |

SOT23-3 |

USB ESD |

Orientation stripe |

ESDA6V1W5 |

Circuit board components ensure that electronic devices operate reliably and accurately. Each component has a specific task to perform. If any component fails, it can disrupt the entire circuit and cause the device to malfunction or fail completely.

The size of electronic devices has decreased significantly over the years, and circuit board components have played a crucial role in making this possible. By using smaller and more efficient components, manufacturers can create devices that are compact, lightweight, and easier to transport.

Using standardized circuit board parts has made electronic gadgets cheaper. Manufacturers can reduce production costs by using commonly available components, which means gadgets are now more affordable for customers.

Manufacturers can create unique devices that meet the needs of their customers by customizing circuit board components to fit specific applications. This flexibility also allows for the development of new technologies and innovations that can improve the performance of electronic devices.

Circuit board components are subject to rigorous quality control standards to ensure that they meet specific performance and safety requirements. These standards help to ensure that electronic devices are safe to use and reliable.

circuit board components are critical to the functioning of electronic devices. These components allow for reliable operation, efficient use of space, cost-effectiveness, flexibility, and quality control. As technology continues to advance, the importance of circuit board components will only continue to grow, and new innovations in this field will enable the development of even more advanced and sophisticated electronic devices.

Circuit board components are designed to be very small in size, which makes them easy to place in a compact manner. Small electronic devices like smartphones, wearables, and other portable devices benefit greatly from this, as it saves space. The small size also allows for more efficient use of available space within the device, which can lead to a more optimal design.

Circuit board parts are made to be easy to change and fix. This saves money because it's cheaper to maintain and repair electronics. Since the parts are all the same, it's easy to find new ones, and repair people can easily figure out and fix problems. This saves time and money in the long run by reducing the need for expensive fixes or replacements.

Circuit board parts are made very accurately so they work correctly. This is super important because even tiny differences can mess up electronic devices. These parts are designed to work really well so electronic devices can work at their best.

Electronic parts on circuit boards are made in big amounts, which makes it cheaper to make electronic devices. This means people and companies can buy them at lower prices. Plus, making lots of these parts helps to save money due to the big amount made.

Designers create circuit board components for optimal function, ensuring peak performance levels in electronic devices. This is especially important for devices that require high precision and accuracy, such as medical equipment, aerospace technology, and military equipment. By using circuit board components, these devices can perform at their best, which can have significant benefits in terms of safety, reliability, and efficiency.

The design of circuit board parts cannot easily be changed to meet specific requirements. This is a problem for industries like aerospace and the military that need unique parts. It's also tough for businesses that want specific features in their electronics.

Making circuit board components is expensive at first. This is hard for small manufacturers. Buying materials and machines, hiring skilled workers, and setting up a production line cost a lot, especially for new or small businesses. This can make it tough for them to compete with bigger businesses.

Making circuit board parts creates a lot of garbage that can harm nature. Using dangerous chemicals like lead, mercury, and cadmium can pollute and harm the environment. It's tough to throw away electronic waste because it often has dangerous stuff in it that can hurt people and the environment.

Fixing broken circuit board parts is hard because they're tiny and complicated. It can be tough for regular folks to figure out what's wrong and fix it. This can make fixing the device take longer, cost more money, and sometimes you have to replace the whole thing.

The inflexibility of circuit board components limits the ability to adjust the design of electronic devices after manufacturing. This can be a problem for industries that require a high degree of flexibility in their products, such as consumer electronics or medical devices. It can also be a challenge for businesses that need to make changes to their products quickly and efficiently in response.

Pick packages your assembler likes and your board can handle. Very tiny parts save space but raise placement difficulty and rework cost. Check stencil, keep-outs, and height near panel rails.

Choose voltage, current, power, and temperature ratings with margin. For example, give caps headroom for DC bias, pick inductors that won't saturate, and use temperature grades that match the real world your product lives in.

Match the metric to the part type: resistor tolerance/TCR, capacitor ESR and ripple current, inductor DCR and saturation, diode forward drop/leakage, MOSFET RDS(on) at your actual gate drive, and IC accuracy and PSRR. Don't over-spec where it doesn't help.

Heat, vibration, humidity, dust—design for them. Electrolytics age faster when hot, connectors loosen under shock, and unprotected metals corrode. Use the right materials, coatings, and life ratings.

Favor parts with multiple sources or easy alternates, healthy stock, and no looming EOL. Keep an approved-vendor list and a second choice in the same footprint when possible.

Unit price is only part of it. Count assembly time, yield, test complexity, EMI fixes, heatsinks, and rework. Sometimes one slightly pricier IC replaces several cheaper ones and lowers total cost.

Check RoHS/REACH, safety standards, flammability ratings, and creepage/clearance where high voltage is involved. Certain markets (auto, medical, avionics) have extra rules—plan for them early.

Clear silkscreen, polarized footprints, access to programming and test points, and parts that AOI can read will save you from production escapes and field headaches.

Stable datasheets, app notes, reference designs, and clear PCN/change control make your design more robust over the product's life.

PCBs can stop working because they're old. This can make them not work right. When PCBs get old, parts like diodes, transistors, and transformers can also break and not work right. These parts usually last around 10 years. So, after 10 years, it might be time to replace them so everything works as it should.

It's hard to stop printed circuit board parts from getting old, but replacing them is expensive. To stop PCB parts from aging, use good quality materials when making them. Also, put the parts in the right place, and don't use burned parts. If you use burned parts, they might get old fast.

To avoid rapid aging, employ the best soldering techniques during the assembly process. Chemical or fluid leakage during soldering can also cause aging. Proper care should be taken to prevent such leaks.

To prevent PCB aging, here are some tips to consider:

Use high-quality materials during PCB manufacturing: High-quality materials are less likely to degrade and malfunction quickly, leading to less aging.

Proper component placement: Correctly placing components is important to prevent stress and extend their lifespan.

Avoid burn components: Burne components will age quickly, leading to premature failure. Therefore, it's crucial to avoid using burned components during assembly.

Employ the best soldering techniques: The use of proper soldering techniques will prevent unnecessary stress on the components, leading to less aging.

Avoid chemical or fluid leakage during soldering: Chemical or fluid leakage during soldering can cause aging, leading to premature failure. Proper care should be taken to prevent such leaks.

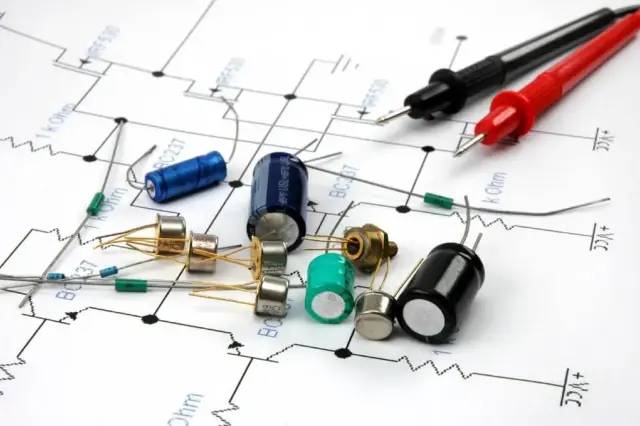

Parts on a printed circuit board are linked in different ways depending on the component type, the required electrical connection, and the space on the board. Below are some common ways of connecting components on a PCB:

Surface Mount Technology (SMT) is a method of linking small parts like resistors, capacitors, and integrated circuits to a PCB. We join SMT parts with metal tabs or balls on the bottom straight to copper pads on the PCB. Usually, automated machines are used to quickly and accurately place and solder the parts onto the board. > Recommend reading: Circuit Board Solder: Types, Temperatures & How to Choose (with Reflow & Hand Soldering Tips)

SMT saves space and lets you make smaller, more compact PCB designs.

Through Hole Technology (THT): This way is for bigger parts like plugs, buttons, and power suppliers.

The wires are inserted into pre-made holes in THT pieces and then soldered onto copper spots on the opposite side of the board. This method gives a firm and robust connection, but it uses up more room on the PCB and takes more time to put together."

Pin Grid Arrays (PGAs): These are used for high-density components like microprocessors and memory chips. Soldering directly to the copper pads on the PCB, the grid of small pins in PGAs provides a very secure connection and enables a large number of pins to connect to the board in a small space.

Overall, the method used to connect components on a PCB will depend on the type of component, the desired electrical connection, and the available space on the board. PCB designers must carefully consider these factors when choosing the most appropriate method for connecting components on a given board.

Recommond reading: Building Better PCBs: Key Design Strategies and Modern Manufacturing Tips

This section explores the key differences between SMD and Through-Hole (THT) components, which are critical in the design and assembly of a printed circuit board (PCB). Understanding the strengths of each package type will help you make the right component choices when creating your circuit board components list, ensuring smooth integration during the assembly process.

SMD components are placed directly on the surface of the PCB and soldered using reflow soldering. They come in a variety of sizes, including 01005–1206, and packages like SOT-23, SOIC/SOP, QFP, QFN, and BGA. SMD components allow for higher component density and double-sided assembly, which is ideal for compact designs. Ball Grid Arrays are especially useful for high-speed designs because they provide many input/output connections with short electrical paths and low inductance.

Through-hole components have leads that go through holes in the PCB and are soldered from the opposite side. They are typically used for components that need to handle higher power or mechanical stress, such as TO-220 transistors, radial electrolytics, large connectors, and switches. The main disadvantage is that these components take up more space and require extra assembly steps like drilling.

Most PCBs use a combination of SMD and THT components. SMD components are often used for smaller, lower-power parts to maximize board space and reduce costs, while THT components are used for larger, high-power parts and connectors where strength and reliability are crucial.

Before selecting component packages, it's important to check your assembler's capabilities. Consider factors such as the minimum pitch (e.g., 0.4 mm QFN/BGA), the smallest component size that can be placed (e.g., 01005/0201), the need for X-ray inspection of BGAs, stencil thickness, and the design rules for wave or hand soldering. Ensuring that your components and design align with assembly capabilities will help avoid costly rework and delays.

As technology continues to evolve, the demand for smaller, more powerful, and more efficient circuit board components is increasing. Consequently, some of the future trends in circuit board components are:

The use of AI and IoT is growing, resulting in the development of specialized parts for handling and studying big data.

As we need to process things faster, we'll need more powerful parts that work faster. That means we'll have to make new stuff that can handle higher speeds without getting worse.

The trend for saving energy will continue, requiring improved parts that can handle higher voltage but use less power.

The integration of multiple functions into a single component will become more common. We need new ways of making things that can do more than one thing, but still, work well and are dependable.

Quick quote service:

NextPCB simplifies the PCB ordering process with its quick and easy-to-use PCB quote service & PCBA quote service. Customers can get instant quotes based on their specific requirements, making it convenient to plan and budget their PCB projects. With transparent pricing and quality assurance, NextPCB ensures a smooth and reliable PCB manufacturing experience.

PCB Assembly Services:

NextPCB also provides professional PCB assembly services, offering end-to-end solutions for customers' electronics manufacturing needs. Their experienced team ensures the highest level of quality and efficiency throughout the assembly process, providing seamless integration of components into the circuit board.

Gerber Viewer:

NextPCB's Gerber Viewer is an essential tool for PCB designers and engineers. It allows users to view and analyze Gerber files, ensuring the accuracy and correctness of their PCB designs before manufacturing. This free online tool offers convenience and confidence in the PCB manufacturing process.

Quick Turnaround Times:

They know that in today's fast business world, time is important, and delays can be bad. So, they work quickly on urgent projects without sacrificing quality.

Customization Options:

NextPCB lets you make your own circuit boards by choosing how it looks, picking what parts to use, and even getting help putting it all together. Furthermore, this means that you can tailor your components to meet your specific requirements.

Technical Support:

NextPCB provides technical support to their customers, including assistance with design and manufacturing issues. This can be very useful if you have any issues while making the product.

Environmentally Friendly:

NextPCB cares deeply about sustainability. They make an effort to use materials and methods that are good for the environment whenever they can, to show how much they care about sustainability.

Understanding circuit board components, how to perform pcb components identification, and how to compile a clean pcb parts list is the foundation of reliable, scalable electronics manufacturing. Pair that knowledge with smart DFM/DFA, clear capabilities checks, and the right testing strategy, and you’ll ship robust products faster—with fewer surprises on the line.

When you're ready, validate your files in HQDFM, review capabilities, and book turnkey PCBA to turn your printed circuit board components into working products.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now