Support Team

Feedback:

support@nextpcb.comTable of Contents

In electronics, every circuit, whether it powers a smartphone, a medical device, or an industrial control system, is built from a combination of active and passive electronic components. Understanding how these components differ, how they function, and how they work together is a fundamental requirement for students, design engineers, and manufacturers involved in PCB design and PCBA assembly.

At the most basic level, the distinction between active vs passive electronic components lies in their interaction with electrical energy. Active components can control or amplify signals and require an external power source, while passive components do not provide gain and operate using the energy already present in the circuit. This difference directly influences circuit behavior, power consumption, signal integrity, and overall system reliability.

However, the classification is not always straightforward. Real-world circuits often combine both component types in tightly coupled ways, especially in power electronics, signal conditioning, and mixed-signal designs. Components such as diodes used in bridge rectifiers highlight this gray area, where semiconductor devices exhibit controlled behavior without signal amplification, yet remain critical to AC-to-DC conversion in power supply circuits.

This article provides a clear, technical comparison of active and passive electronic components, covering definitions, differences, examples, applications, and real-world use cases. By the end, readers will understand not only how these components are classified, but why the distinction matters in practical circuit design and PCB assembly.

Active electronic components are components that require an external power source to operate and are capable of controlling, amplifying, or switching electrical signals within an electronic circuit.

From a technical standpoint, active components can introduce power gain into a circuit. This means a small input signal can control a larger output signal, a property that is fundamental to amplification, digital logic, and signal processing. Most active components are built using semiconductor materials such as silicon and rely on controlled charge carrier movement under biasing conditions.

In practical circuit design and PCB assembly, active components define the functional behavior of a system. Microcontrollers execute logic, transistors switch and amplify signals, and integrated circuits manage power, communication, and computation. Without active components, a circuit cannot process information or perform complex operations.

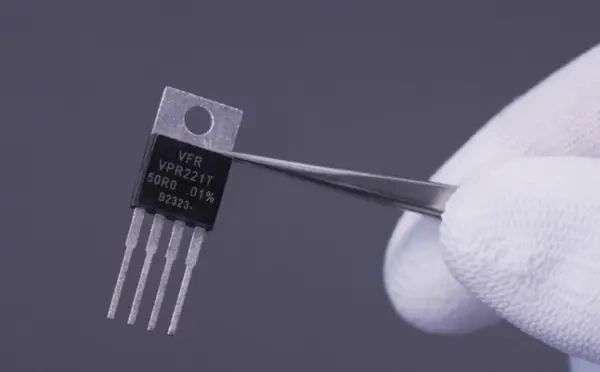

Transistors are among the most fundamental active components in electronics, operating by using a small input signal to control a larger current or voltage. This property enables both signal amplification and switching, making transistors essential in analog and digital circuits alike. Common transistor types include Bipolar Junction Transistors (BJTs), which are current-controlled devices, and Metal–Oxide–Semiconductor Field-Effect Transistors (MOSFETs), which are voltage-controlled and widely used in digital and power electronics. Understanding the difference between BJTs and MOSFETs helps engineers make better design choices in terms of efficiency, switching speed, and power consumption for specific applications.

In practical circuit implementation, transistor performance extends beyond the device itself and is closely tied to how it is integrated onto the printed circuit board. Factors such as footprint accuracy, thermal dissipation, component placement, and routing significantly influence reliability and electrical behavior, especially in high-frequency or high-current designs. These considerations underscore the importance of PCBA processes and the key assembly factors that affect how components function once mounted on the board, including material selection, soldering quality, and layout optimization.

Integrated circuits (ICs) combine multiple active and passive elements, primarily transistors, into a single compact package, allowing complex electronic functions to be performed efficiently and reliably. Common examples include microcontrollers used for embedded control, operational amplifiers for signal conditioning, power management ICs that regulate voltage and current, and communication or interface ICs that enable data exchange between systems. From a classification standpoint, ICs are considered active components because they require an external power source and actively process, amplify, or control electrical signals.

In modern electronic systems, ICs dominate PCB layouts, particularly as devices become smaller and more functionally dense. This makes factors such as component sourcing, package compatibility—including formats like QFN, BGA, and SOP—and assembly precision increasingly critical to overall system performance. The success of these designs depends heavily on reliable PCB manufacturing and assembly practices that support accurate placement, proper soldering, and thermal reliability, especially in high-density applications. For readers new to PCB design, an overview of commonly used PCB components provides useful context for understanding how ICs fit into broader board-level assemblies.

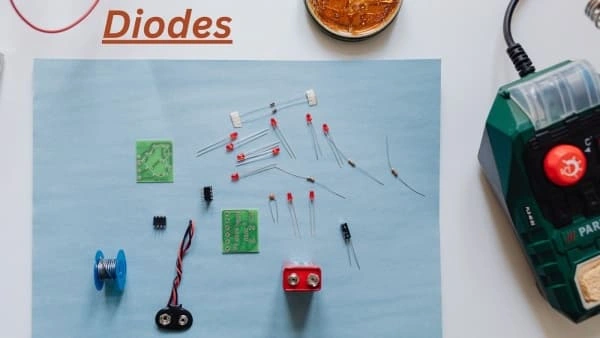

Diodes are semiconductor devices that allow current to flow in only one direction, a behavior made possible by their PN junction structure. Although diodes do not amplify signals, they are classified as active components because their operation depends on nonlinear semiconductor properties that actively control current flow. This controlled behavior is fundamental to many electronic functions, particularly in power conversion applications.

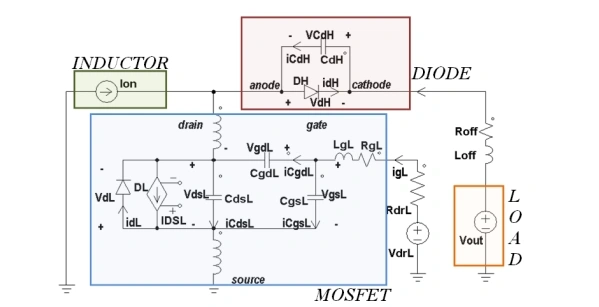

One of the most common real-world uses of diodes is in bridge rectifiers, which are circuits designed to convert alternating current (AC) into direct current (DC). A bridge rectifier employs four diodes arranged so that, during each half-cycle of the AC input, a different pair of diodes conducts. Regardless of whether the input voltage is in its positive or negative half-cycle, the configuration ensures that the output polarity remains constant, producing a pulsating DC signal.

While a bridge rectifier does not amplify voltage, it actively governs the direction of current flow, a function that is essential in power supply design. In electronic systems, rectifiers are rarely used in isolation; they are typically followed by passive components such as smoothing capacitors and, in some cases, inductors to reduce ripple, before active voltage regulators stabilize the output. This interaction illustrates how active and passive components work together to deliver reliable DC power in real circuits.

Passive electronic components are components that do not require an external power source and cannot amplify or generate electrical signals. They operate solely using the electrical energy already present in the circuit.

Technically, passive components can store, dissipate, or transfer energy, but they never provide power gain. For example, resistors dissipate energy as heat, capacitors store energy in an electric field, and inductors store energy in a magnetic field. Their electrical behavior is typically linear and predictable, making them essential for circuit stability and control.

In real-world electronics, passive components play a supporting but critical role. They set operating points for active devices, filter noise, stabilize power rails, shape signal waveforms, and protect sensitive components. Every functional electronic system relies on passive components to ensure reliability, efficiency, and signal integrity.

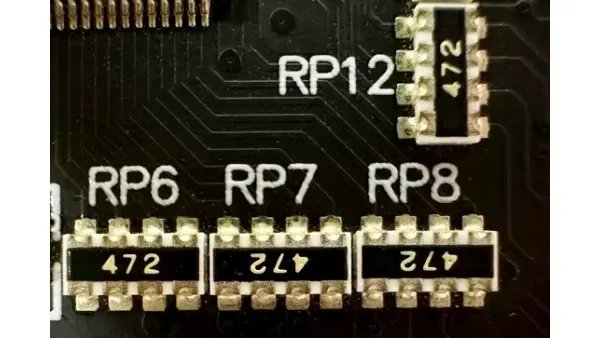

Resistors are passive components that regulate current flow, divide voltage, and establish stable biasing conditions for active devices within electronic circuits. They play a critical role in functions such as voltage division, pull-up and pull-down configurations in digital logic, and current limiting for circuit protection. Without properly selected resistors, both analog and digital systems would struggle to operate within safe and predictable electrical limits.

At the board level, resistor performance is influenced not only by its nominal resistance value but also by factors such as tolerance, power rating, and temperature stability. In PCB assembly, these characteristics directly affect overall circuit accuracy and reliability, particularly in analog signal processing and sensing applications where small deviations can lead to significant measurement errors or drift.

Capacitors are passive components that store electrical energy in an electric field and are fundamental to stable and reliable circuit operation. They are widely used to smooth power supply outputs, provide decoupling and bypassing for noise reduction, and enable signal coupling and timing functions in both analog and digital designs. Their ability to momentarily store and release energy makes them especially important in circuits where voltage stability is critical.

In power supply designs that incorporate bridge rectifiers, capacitors play a key role in reducing ripple voltage by filtering the pulsating DC produced during rectification and transforming it into a smoother DC output. This behavior underscores the reliance of active semiconductor circuits on passive energy-storage components to maintain consistent performance. At the PCB level, proper capacitor selection, package type, and placement are equally important, particularly in surface-mount designs where component identification and layout directly influence electrical characteristics and assembly outcomes. A practical understanding of surface-mount capacitor types and identification methods helps ensure correct implementation during PCB assembly.

Inductors are passive components that store energy in a magnetic field and oppose rapid changes in current, a property that makes them indispensable in many electronic systems. They are commonly used in switching power supplies to manage current flow, in electromagnetic interference (EMI) suppression to reduce noise, and in radio-frequency (RF) circuits where precise signal behavior is required. By resisting sudden current variations, inductors help stabilize circuit operation and protect sensitive components.

Transformers can be understood as magnetically coupled inductors and are widely used in alternating current (AC) power systems to perform voltage conversion and provide electrical isolation. In many power supply designs, transformers operate upstream of rectification, conditioning the AC input before it is converted to DC by diode-based circuits. This sequence highlights the complementary roles of passive magnetic components and active semiconductor devices in power electronics.

| Feature | Active Components | Passive Components |

|---|---|---|

| External power required | Yes | No |

| Signal amplification | Yes | No |

| Power gain | Possible | Never |

| Energy control | High | None |

| Examples | Transistors, ICs, Diodes | Resistors, Capacitors, Inductors |

| Role in circuits | Processing, switching, regulation | Filtering, storage, stabilization |

| PCB impact | Defines functionality | Ensures reliability and integrity |

| Typical use cases | CPUs, amplifiers, regulators | Power smoothing, noise reduction |

Active and passive electronic components rarely operate in isolation from one another. In real-world systems, performance, reliability, and manufacturability depend on how well these components are combined, placed, and assembled on a PCB. Below are key application areas where their interaction is critical.

>> To see how these active and passive component applications translate into PCB design and manufacturing across key sectors, explore our PCB Applicable Industries & Solutions guide.

Power supply circuits provide one of the clearest demonstrations of how active and passive electronic components work together to deliver stable and usable electrical energy. In a typical AC-to-DC power supply, transformers are first used to step down the input voltage, after which bridge rectifiers, composed of diodes, convert the alternating current into direct current. Passive filtering elements, such as capacitors and inductors, then reduce ripple and suppress noise, preparing the signal for active voltage regulator ICs that maintain a consistent output voltage under varying load conditions.

Because these systems handle both high currents and sensitive control signals, even minor PCB layout errors, such as inadequate grounding, insufficient copper width, or poor thermal paths, can lead to noise coupling, excessive heat buildup, or reduced efficiency. As a result, PCB fabrication quality and PCBA process control play a critical role in the reliability and performance of power electronics. Ensuring that both active semiconductor devices and high-current passive components are assembled with correct polarity, spacing, and thermal considerations is essential for long-term stability.

Audio amplification circuits depend heavily on active components such as transistors and operational amplifiers to boost weak input signals to usable levels. However, overall performance is shaped just as much by passive components that define gain, frequency response, and noise behavior. Resistors establish precise gain and biasing conditions, capacitors enable signal coupling and frequency filtering, and inductors are often used to suppress unwanted noise and interference, particularly in sensitive analog stages. The quality of audio output is strongly influenced by how these components are implemented on the PCB.

Poor assembly practices, parasitic capacitance from improper trace routing, or incorrect component placement can introduce distortion, noise, or signal loss. Professional PCB assembly plays a critical role in preserving signal integrity, especially in low-noise analog designs where component tolerances, grounding strategies, and soldering quality directly affect clarity and overall sound performance.

Communication systems, including Wi-Fi modules, IoT devices, and RF transmitters, rely on a precise balance between active and passive components to function effectively. Active components are responsible for generating, amplifying, and processing RF signals, while passive components handle tasks such as impedance matching, filtering, and antenna tuning to ensure signal integrity and efficiency.

At high frequencies, factors such as PCB material selection, trace geometry, and component placement become just as critical as the components themselves. Even small deviations in layout can degrade performance, introduce signal loss, or create unwanted interference. This is why RF designs benefit from PCB manufacturers experienced in high-density surface-mount layouts and controlled-impedance boards, which support accurate component placement, reliable soldering, and controlled impedance to support high-performance, high-frequency circuits.

Medical and precision electronic devices demand the highest levels of reliability and consistency, making both component interaction and assembly quality critical. Active components, such as sensors and amplifiers, capture and process delicate physiological signals, while passive components, like filters, reduce noise and ensure signal clarity. Power regulation circuits further maintain stable operation, which is essential for device safety and accuracy.

In these applications, failure is not an option, and every detail, from proper component identification and correct soldering to thorough testing, directly impacts performance and safety. Experienced PCB manufacturers play a crucial role in this process by ensuring precise assembly, stringent quality control, and adherence to design specifications.

Renewable energy systems, including solar inverters and motor controllers, rely on a careful integration of active and passive components to manage and convert electrical energy efficiently. Active power devices such as MOSFETs, IGBTs, and control ICs regulate and switch high currents, while passive components like capacitors, inductors, and transformers provide energy storage, filtering, and voltage transformation. Bridge rectifiers are commonly used in AC input stages, and passive filtering networks help ensure clean DC outputs before active regulation is applied.

These systems frequently operate under high voltages, high currents, and challenging environmental conditions, making robust design and precise assembly essential. Reliable PCB manufacturing and PCBA services are critical for long-term performance and safety, ensuring that both high-power active devices and passive energy-handling components are placed accurately, soldered correctly, and thermally managed.

The performance, reliability, and longevity of any electronic device depend not only on selecting the right active and passive components but also on how these components are integrated onto the printed circuit board. Proper integration ensures that circuits function as intended, signal integrity is maintained, and potential issues such as noise, crosstalk, or thermal stress are minimized. In complex designs, ranging from high-frequency communication systems and audio amplifiers to power electronics and medical devices, the precise placement, orientation, and spacing of each component can significantly influence overall system behavior.

For example, even slight misalignment of diodes or capacitors can result in polarity errors, affecting rectification or voltage regulation, while improper soldering on dense SMD layouts can introduce unreliable connections, parasitic resistance, or intermittent failures. Accurate component placement also affects thermal management, especially in high-power circuits where heat dissipation is critical to prevent degradation of both active and passive elements. Additionally, considerations such as trace routing, grounding, and component proximity play vital roles in ensuring high-speed signal integrity and minimizing electromagnetic interference (EMI).

NextPCB’s PCB fabrication and PCBA services are specifically designed to address these challenges across the full spectrum of electronics manufacturing. Their capabilities support precise placement of both active and passive components, correct polarity handling for sensitive devices like diodes and electrolytic capacitors, and high-quality soldering even on dense surface-mount layouts. Moreover, NextPCB provides scalable solutions, from rapid prototyping to large-scale production, ensuring consistency and reliability at every stage. For a deeper understanding of how NextPCB’s manufacturing and logistics solutions streamline component integration and assembly, their overview of free shipping and full-service support offers valuable insights.

Despite being a foundational topic in electronics, active vs passive electronic components is often misunderstood. These misconceptions appear frequently in classrooms, online forums, and even early-stage design reviews. Clearing them up is essential for accurate circuit design and reliable PCB assembly.

This is one of the most common misunderstandings.

While diodes do not amplify signals, they are semiconductor devices that exhibit nonlinear, direction-controlled behavior. Because they rely on PN junction physics and controlled conduction, diodes are generally classified as active electronic components.

In practical applications, such as bridge rectifiers used in power supplies, diodes actively control current direction to convert AC to DC. Their correct orientation and placement during PCB assembly are critical, as a single reversed diode can cause complete circuit failure.

Passive components may not “do the thinking,” but without them, active components cannot function correctly. Resistors set biasing conditions, capacitors stabilize power rails, and inductors suppress noise. In power supply circuits, passive components work alongside active devices to smooth rectified voltages and protect sensitive ICs from ripple and transients. In PCB manufacturing and PCBA, incorrect passive component values or poor solder joints often cause more failures than active component defects—highlighting their critical role in real-world electronics.

Although integrated circuits (ICs) are classified as active components, they often contain a combination of active and passive elements within a single package. For instance, transistors inside an IC perform switching and amplification functions, while internal resistors and capacitors help shape timing, stabilize signals, and maintain proper circuit behavior. Despite these internal elements, external passive components are still essential around ICs on a PCB to ensure optimal performance.

Passive components cannot provide power gain. While circuits using only passive components can modify voltage or current levels (such as in transformers or voltage dividers), any apparent increase comes at the expense of current or power. True amplification, where output power exceeds input power, requires active components supplied by an external energy source.

In practice, whether a component is classified as active or passive has direct implications for PCB assembly processes and overall reliability. Active components, such as transistors and ICs, often require careful thermal management to prevent overheating and ensure long-term performance. Passive components, including resistors, capacitors, and inductors, vary widely in tolerance, power ratings, and material characteristics, all of which influence their placement and handling during assembly. Also, polarity-sensitive semiconductor devices are common sources of assembly errors and rework if incorrectly oriented.

The main difference is that active electronic components require an external power source and can amplify or control signals, while passive components do not require power and cannot provide signal amplification. Passive components store, dissipate, or transfer energy, supporting the operation of active devices in electronic circuits.

Diodes are generally classified as active electronic components because they are semiconductor devices with nonlinear behavior. Although they do not amplify signals, they actively control current direction, which is why they are essential in applications such as bridge rectifiers used in power supplies.

A bridge rectifier uses four diodes (active components) to convert AC to DC. It relies on passive components such as capacitors and inductors to smooth the output voltage. This combination clearly demonstrates how active and passive components work together in real‑world electronic systems.

Integrated circuits are active components because they require external power and contain active devices such as transistors. However, ICs also include internal passive elements and still depend on external resistors and capacitors for stability, filtering, and proper operation on a PCB.

No. Passive components cannot amplify signals because they do not provide power gain. Any increase in voltage or current achieved using passive components comes at the expense of another parameter, such as current or power, and does not constitute true amplification.

Passive components are critical for signal integrity, power stability, noise reduction, and protection. In PCB and PCBA design, incorrect passive component values, poor placement, or faulty soldering can cause instability or failure—even when all active components are functioning correctly.

Component classification affects polarity handling, thermal management, placement accuracy, and inspection processes. Active components often require careful heat dissipation, while passive components demand precise value selection and orientation. Experienced PCB manufacturers like NextPCB factor these differences into their assembly workflows to ensure reliability.

The distinction between active and passive electronic components goes far beyond textbook definitions. In real-world electronics, these components work together to define how circuits behave, how reliably they operate, and how efficiently they can be manufactured.

Active components such as transistors, integrated circuits, and diodes provide control, amplification, and decision-making capabilities, while passive components such as resistors, capacitors, and inductors ensure stability, energy management, and signal integrity. Practical circuits—from audio amplifiers to power supplies—depend on this balance. The bridge rectifier, which combines semiconductor diodes with passive filtering components, is a clear example of how both classes are inseparable in functional electronic systems.

For engineers, students, and product developers, understanding these differences directly influences component selection, circuit design, PCB layout, and assembly quality. Reliable electronics are not just about choosing the right components, but also about how well they are integrated and manufactured.

This is where experienced PCB and PCBA partners add value. By supporting accurate component identification, high-quality PCB fabrication, and precise assembly processes, NextPCB helps ensure that both active and passive components perform exactly as intended—whether in prototypes, low-volume runs, or full-scale production.

Get BOM Services Engineer Consultation

>> About the Author

Abiola Ayodele: Broadcast Journalist & Tech Writer; Cooperate writer of NextPCB.

Specialize in technical writing, and editing, particularly in the areas of PCB design, semiconductors, cybersecurity, and emerging engineering technologies.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now