Support Team

Feedback:

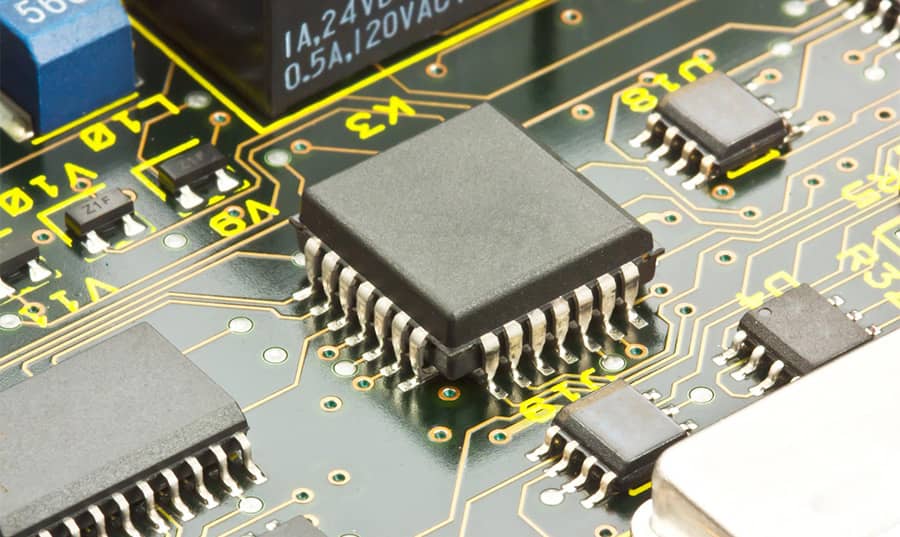

support@nextpcb.comIn daily life, you may encounter the abbreviation SMD in different contexts. In the medical field, it might refer to "Senile Macular Degeneration"; on social media, it can sometimes be used as a less polite abbreviation; and in music or management, it has its own significance. However, when you open your sleek smartphone or observe the densely packed, sesame-sized components on a computer motherboard, SMD takes on a highly technical identity: Surface Mounted Device. It is the cornerstone of modern electronics, enabling our devices to transform from bulky equipment into the portable wonders we carry today. Today, we will delve into the meaning, full name, and crucial role of SMD in PCB manufacturing from the perspective of an experienced electronic engineer.

The SMD full form stands for Surface Mount Device. In the electronics manufacturing field, SMD is often confused with SMT, so understanding their differences is the first step:

From an engineering perspective, SMD is an electronic component specifically designed for direct mounting on the surface of PCB pads. It fundamentally differs from traditional through-hole components (Through-Hole Technology, THT):

As an engineer who's spent years on the factory floor, I always say: The move to SMD wasn't about aesthetics—it was about efficiency, scalability, and reliability.

Twenty years ago, a resistor could be as big as half a matchstick. Now, commonly used 0201 packages (0.6mm x 0.3mm) and even 01005 packages are almost invisible to the naked eye. This leap in size allows us to integrate thousands of functional units on a PCB the size of a business card.

SMD components have either no leads or very short ones. This means:

Understanding SMD specifications is just the starting point; ensuring high yields in large-scale automated production is the real expertise. Below are the core steps in the SMT production line and practical tips to avoid "manufacturing disasters."

In EDA software, the design of the footprint directly affects soldering quality, determined by pad size and connection method.

About 70% of SMD soldering quality depends on solder paste printing.

This is the "main event" of the SMT line, where automatic pick-and-place machines operate at speeds of thousands of units per hour.

To facilitate memorization, we categorize SMDs into the following major types:

| Type | Representative Components | Common Packages | Engineer Comments |

|---|---|---|---|

| Passive Components | Resistors, Capacitors, Inductors | 0402, 0603, 0805, 1206 | The smaller they are, the harder they are to solder; manual repair is nearly impossible. |

| Diodes & Transistors | Transistors, Rectifiers | SOT-23, SOT-89, SOD-123 | Evergreen choices for power conversion and signal switching. |

| Integrated Circuits (IC) | Processors, Memory | QFP, SOP, BGA, QFN | The exposed pad on the bottom of QFN is critical for heat dissipation. |

| Electromechanical Components | Buttons, Connectors | Side-press Switches, USB-C Female (some) | Mechanical strength is the top priority; SMT connectors often need positioning pins and reinforced solder joints to prevent being ripped off during plugging. |

In PCB manufacturing, after SMDs complete reflow soldering, we ensure they live up to their specifications through the following methods:

> Recommend reading: How does NextPCB conduct quality control?

If someone asks you, "What is the definition of SMD?", the dictionary answer is straightforward. However, the engineering perspective is more nuanced:

SMD is not just a type of component package; it is the physical foundation of modern electronics manufacturing. Understanding this is not optional; it is an integral part of professional competence.

> Recommend reading: SMT Meaning in Medical, Automotive, Industrial & Consumer Electronics

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now