Driving the Future of Mobility

As the automotive landscape shifts towards electrification and autonomous driving, the vehicle has evolved from a mechanical system to a complex electronic ecosystem. You have arrived here because you understand that modern mobility demands more than just standard circuits—it requires "Engineering for Every Environment."

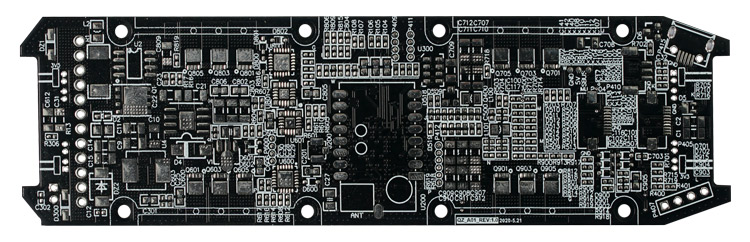

At NextPCB, we bridge the gap between automotive innovation and manufacturing reality. Unlike consumer electronics, automotive PCBs function as the critical nervous system of the vehicle, requiring absolute precision in processing, sensing, and power management. From the powertrain to the infotainment system, our automotive PCB solutions are built to withstand extreme vibrations, thermal fluctuations, and rigorous safety standards.

Matching Our Capabilities to Your Automotive Needs

Drawing from our extensive Advanced PCB capabilities and PCB Assembly capabilities, we provide tailored solutions for specific automotive systems. Here is how NextPCB supports your engineering challenges:

| Automotive System |

Key Technology |

NextPCB Capability |

EV Powertrain & BMS

(Battery Management) |

High Current & Thermal Dissipation |

Heavy Copper PCBs (up to 10oz) and Metal Core PCBs for superior heat management. |

ADAS & Sensors

(Radar, LiDAR, Cameras) |

High Speed & Signal Integrity |

HDI (High Density Interconnect) and High-Frequency materials (Rogers, Teflon) for precise data transmission. |

| ECU & Control Modules |

Compact Design & Reliability |

Rigid-Flex PCBs and Multilayer boards (up to 32 layers) to fit tight spaces without compromising durability |

Why NextPCB is Your Trusted Automotive Partner

In the automotive industry, a defect is not just an error; it's a safety risk. Our manufacturing philosophy is aligned strictly with the zero-defect requirements of Tier-1 suppliers.

- IATF 16949 Certified: We hold the gold standard certification for automotive quality management systems, ensuring traceability and consistency in every batch.

- Full-Cycle Testing & Inspection: Leveraging our in-house testing labs (as seen in our "Testing & Inspection" capabilities), we perform AOI, X-ray, and functional testing to ensure every board meets automotive-grade reliability.

- Turnkey Efficiency: From rapid prototyping for R&D validation to mass PCB manufacturing and assembly, we manage the entire lifecycle. This integrated approach reduces time-to-market for new vehicle models.

Ready to engineer the next generation of vehicles? NextPCB provides the industrial strength, material diversity, and assembly expertise your automotive projects demand.

Looking for More PCB Solutions Across Industries?

Whether it's for electric vehicles (EVs), medical devices, or industrial applications, NextPCB provides the best solutions for your needs.

Back to Industry Hub

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate