Introduction to Potentiometer Wiring

Potentiometers (often called "pots") are indispensable variable resistors in electronics, enabling precise control over electrical current or voltage within a circuit.

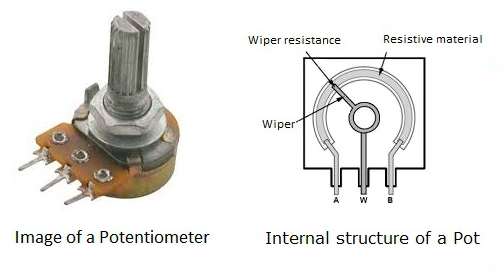

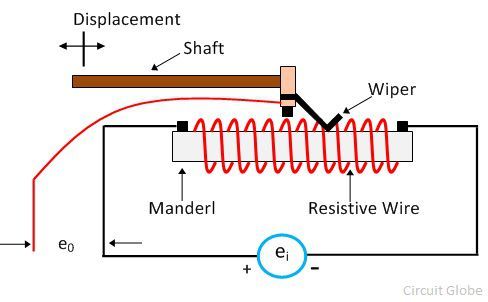

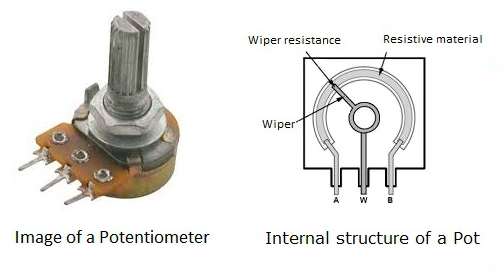

Constructed from resistive materials like carbon, conductive plastic, or wire-wound elements, they feature a stationary resistive track and a movable wiper contact. By adjusting the wiper's position via a knob or slider, the resistance between the wiper and the end terminals changes, providing a tunable output.

For reliable performance in your designs, high-quality PCB manufacturing forms the foundation for precise potentiometer integration.

Why Wiring Matters: Precision is Key

Proper potentiometer wiring is essential for ensuring consistent circuit performance and long-term reliability. Even small wiring mistakes can lead to significant functional issues, especially in precision applications:

- Measurement Systems: Inaccurate wiring can cause noticeable deviations in sensor readings, potentially impacting performance in medical or industrial instruments.

- Automotive/Industrial Applications: Poor grounding or incorrect connections can significantly reduce potentiometer lifespan and overall system stability.

- Audio Systems: Using shielded wiring and proper grounding helps minimize electromagnetic interference, reducing unwanted noise and signal distortion—often by as much as 30–40 dB.

Whether you're adjusting motor speed, calibrating sensors, setting LED brightness, or controlling audio volume, correct potentiometer wiring is key to unlocking full functionality and maintaining dependable operation.

Article Sections

Different Types of Potentiometers

Selecting the right potentiometer type is crucial for your application. Common configurations include:

Linear Taper Potentiometers

Resistance changes linearly (directly proportionally) with the wiper position.

- Example Part: Bourns PTV09A

- The resistance alters along with the movement from one end of the device's element to another in an even-keeled and steady manner. Such kinds of potentiometers are typically seen employed for sound system volume and tone controls or lighting dimmer

Logarithmic (Audio) Taper Potentiometers

Resistance changes logarithmically with the wiper position, mimicking the human ear's loudness perception. Essential for volume controls in audio equipment to achieve natural-sounding volume adjustments.

- Example Part: ALPS RK09K

- Ideal for Audio PCB Designs - Contact our engineers for impedance-matching solutions

- Compared to single-turn potentiometers, multi-turn potentiometers provide far more precise calibrations due to their resistive element that can rotate multiple times. As a result of their precision, these devices are routinely used in instrumentation and measurement systems where accuracy is essential.

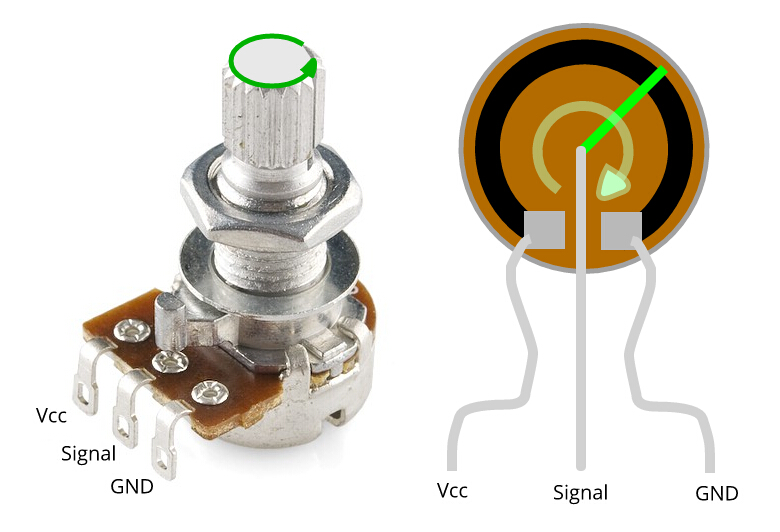

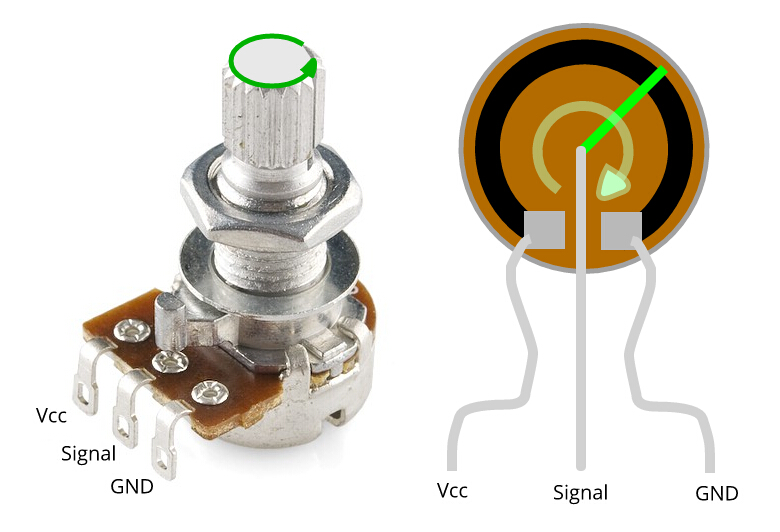

Rotary Potentiometers

The most common type, featuring a rotating shaft to move the wiper. Used for volume/tone controls, panel-mounted adjustments, and parameter setting. Sub-types include single-turn and multi-turn.

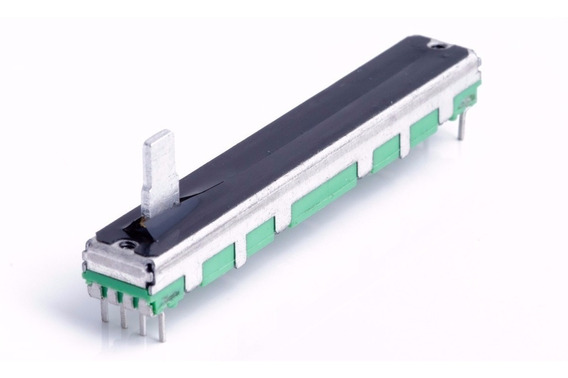

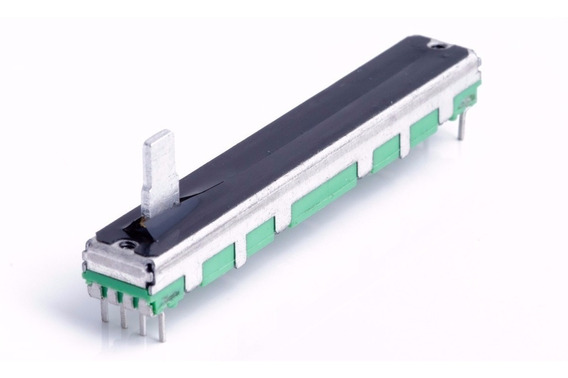

Slide Potentiometers

The wiper moves linearly along a straight resistive element via a sliding knob. Well-suited for graphic equalizers, faders, and space-constrained devices.

- This movement of the slide changes resistance as you move along it. You will often find these types of potentiometers in smaller electronic gadgets like mobile phones and portable audio players due to their size and convenience!

- Require precise footprints - Use our Free DFM Check for SMD compatibility

Multi-Turn Potentiometers

Require multiple rotations (3, 5, 10, 25 turns) of the shaft to traverse the full resistive element. Provide extremely precise resistance adjustment and calibration, vital for instrumentation and critical settings.

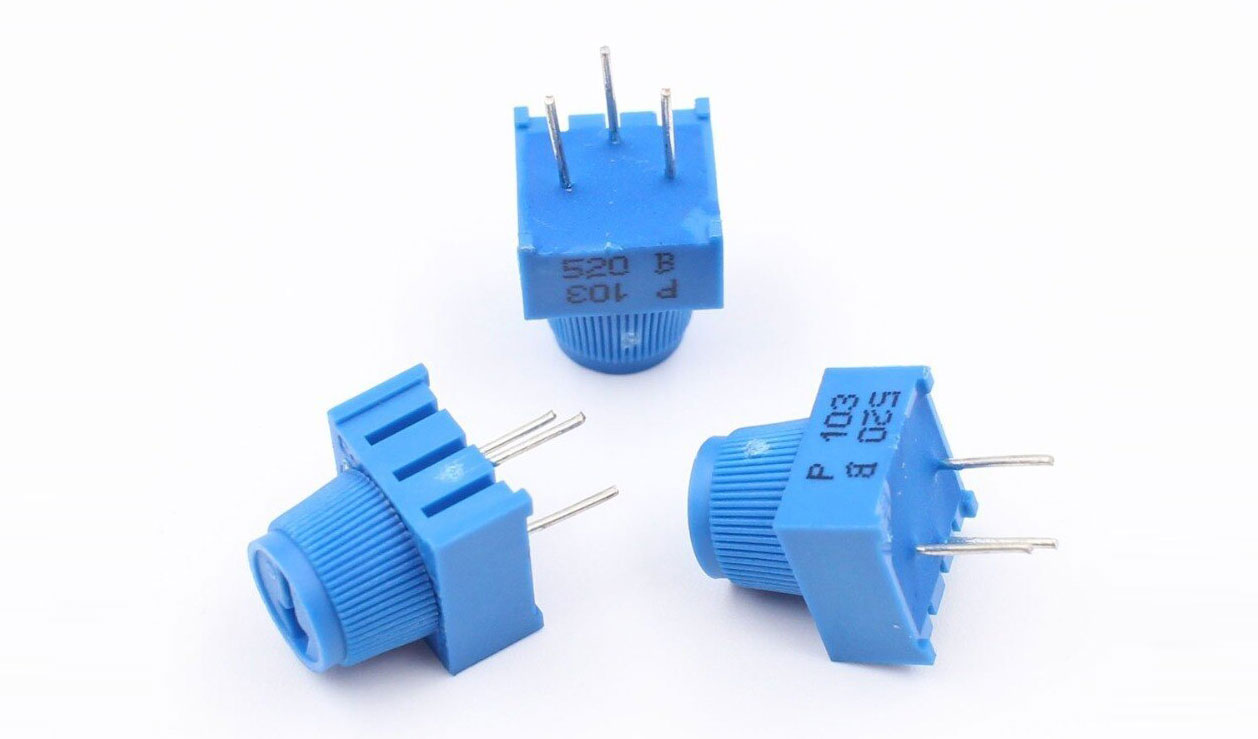

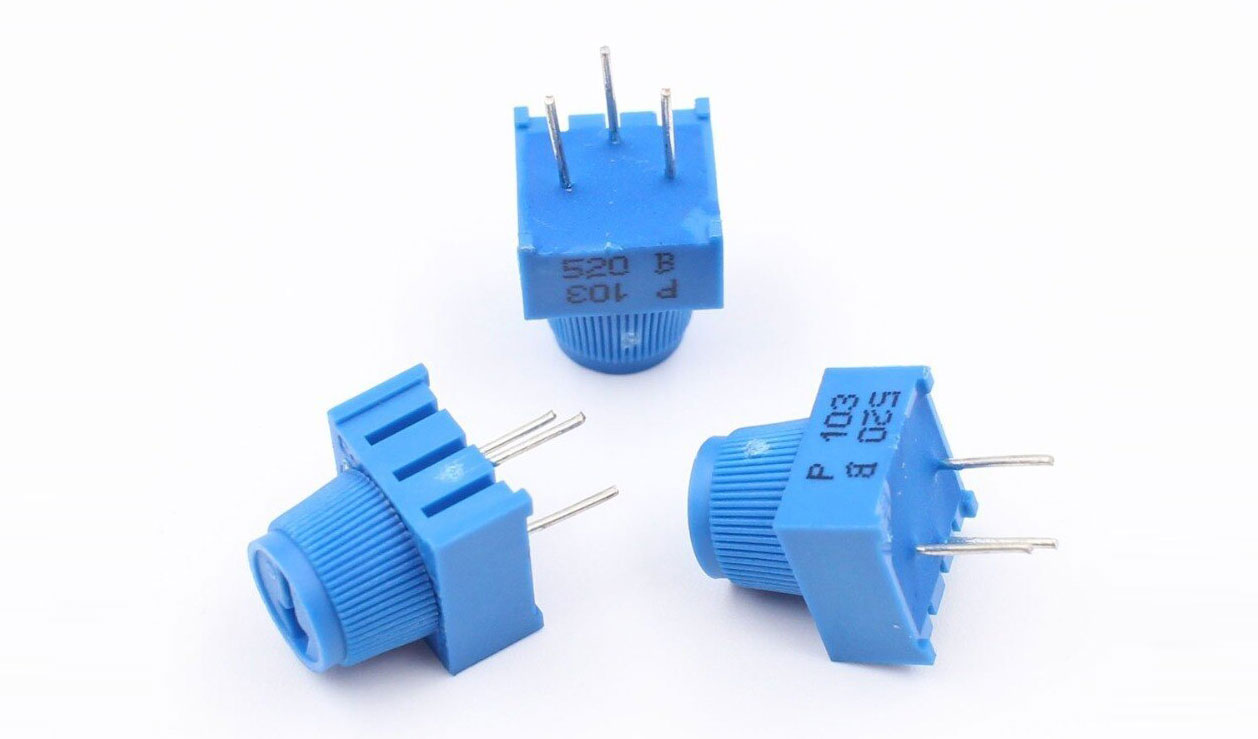

Trimmer Potentiometers

Also known as trim pots or preset potentiometers. Small, panel or PCB-mounted pots intended for "set-and-forget" calibration during manufacturing or servicing. Adjusted with a screwdriver.

- Employing trimmer potentiometers enables adjustments to be made directly to a circuit board without any external interference from end users. This minimizes hassle and maximizes efficiency during manufacturing processes as well as troubleshooting tasks down the line.

Digital Potentiometers ("Digipots")

Use digital signals (e.g., SPI, I2C) to control resistance electronically, replacing mechanical wipers. Enable remote control, automation, and precise, repeatable digital adjustments.

Choosing the Appropriate Potentiometer

Selecting the optimal pot requires careful consideration:

Resistance Value (Ohm Rating)

Must be compatible with circuit requirements. Ranges span from 10Ω to several MΩ. Incorrect values affect current & voltage ranges. Consider: Circuit impedance, desired adjustment range.

Tolerance

Expressed as a percentage (±x%), indicates the accuracy of the nominal resistance value. Use lower tolerance pots (e.g., ±5% or ±10%) where precision matters.

Power Rating (Watts)

The maximum sustained power (I²R or V²/R) the pot can dissipate without overheating. Critical: Ensure circuit current/voltage stresses fall well within the pot's rating (derate for reliability). Example: A 0.5W pot is common for general electronics.

Taper

Linear Vs. Logarithmic. Choose based on the required control response: linear for position/speed/output voltage control, logarithmic for volume. Audio controls almost exclusively require log taper.

Physical Dimensions & Shaft Type

Must fit the enclosure and PCB/front panel layout. Consider shaft diameter, length, knob style (knurled, D-shaft, slotted).

Mounting Type

PCB mount (through-hole or SMD), Panel mount (bushing/nut), or Stand-off mount. Ensure compatibility with assembly design.

Environmental Factors

Consider dust/water sealing (IP rating), temperature range, vibration, and reliability requirements. (Harsh environments? Specify Conformal Coating Services during PCBA assembly)

Potentiometer Wiring Diagram

Potentiometers are commonly used in electronic circuits for controlling the voltage or current flow. Here are some wiring diagrams for different types of potentiometers:

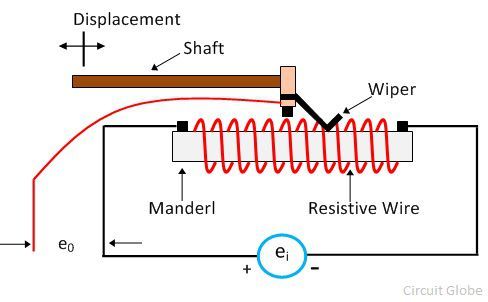

Linear Potentiometer Wiring Diagram

Linear potentiometers have a resistive element that changes linearly with the position of the wiper. Here's how to wire a linear potentiometer:

- Connect one end of the potentiometer to the ground.

- Connect the other end of the potentiometer to the power supply.

- Connect the wiper terminal to the input or output of the circuit.

Here is an example diagram.

Logarithmic Potentiometer Wiring Diagram

A logarithmic potentiometer has a variable resistive element that follows an exponential pattern with the position of the wiper. To wire up this type of device, you must:

- Link one side to the ground for stability.

- Attach the remaining end to your power source in order to provide it energy and current.

- Use a capacitor on its wiper terminal when connecting to either input or output circuits as needed!

Multi-Turn Potentiometer, Slide Potentiometer Wiring Diagram

To wire a multi-turn potentiometer, here's what you need to do:

- Secure one end of the resistive element to the ground.

- Affix the other terminal to the power supply source.

- Connect the wiper side with either an input or output in your circuit layout.

By simply following these steps and rotating its knob multiple times, you can adjust resistance levels as needed!

Troubleshooting Potentiometer Wiring

Common problems and fixes:

Erratic Output / Jumping

- Causes: Loose wiring connections, poor solder joints, internal wiper contamination (dirt, oxidation), damaged resistive element.

- Fix: Check/resecure wiring/soldering. Rotate shaft rapidly full-range 10-20 times to "wipe" internal contacts. Replace if dirty/faulty. Measure resistance between terminals/wipers while adjusting.

No Output or Full Volume/Speed Only

- Causes: Open circuit (broken wire/resistive element), incorrect wiring (wrong terminal connected), short circuit (wires touching), wiper connection failure.

- Fix: Visually inspect wiring for obvious shorts/opens. Verify terminal connections against the appropriate diagram. Use a multimeter for continuity/resistance checks.

Output Stuck at Half Value / Non-functional Control

- Causes: Wiper terminal likely not connected or poorly connected. Terminal B (GND) often inadvertently left floating.

- Fix: Verify all three terminals are correctly connected.

Diagnosing Potentiometer Failure:

- Multimeter Test (Rheostat Mode): Set meter to Ohms (Ω). Measure resistance between Terminal A and the Wiper. Slowly rotate shaft – resistance should change smoothly/consistently. Repeat between Terminal B and Wiper. Full resistance (A to B) should be stable.

Noise / Crackling

- Causes: Internal contamination/wear (See #1), dirty/corroded terminals/solder joints, lack of grounding, poor quality pot or wiring. Particularly noticeable in audio/log taper pots.

- Fix: Clean pot/wire/resolder joints. Consider shielded cable (See Advanced Techniques). Ensure robust chassis/circuit grounding. Replace low-quality components.

Always: Power down the circuit before wiring or troubleshooting. Double-check diagrams before connecting.

Advanced Potentiometer Wiring Techniques

Enhance performance in demanding applications:

- Shielded Wiring: Crucial for low-level analog signals and sensitive audio to prevent EMI/RFI (Electromagnetic/Radio Frequency Interference). Use shielded cable (coax or twisted pair + shield). Connect the shield braid only solidly at one end (usually source/signal ground) to avoid ground loops.

- Precision Buffering: When loading effects from the following circuit affect accuracy (ADC input impedance too low? Motor draws high current? Op-amps distorting?), insert an Op-amp Voltage Follower (Unity Gain Buffer) between the wiper and the load circuit for ideal impedance matching.

- Dual-Gang Pots: Essential for stereo audio controls where left and right channels must be adjusted simultaneously and tracked precisely. Choose matched channels within tolerance.

- Tapered Pots (Log vs. Lin): Tapered potentiometers offer a non-linear resistance curve, making them ideal for circuits that require precise regulation of resistance over an extended range. Take audio systems, for instance; tapered potentiometers are the perfect solution to adjust volume levels as their logarithmic taper surpasses linear in this particular case.

- Trimmer Potentiometers: Use high-quality multi-turn trim pots for critical, infrequent calibration adjustments on PCBs. Document their position during tuning.

- Digital Potentiometers (Digipots): Ideal for microcontroller-based systems needing remote control, automated tuning, or frequent resistance changes. Offers high resolution and non-volatile settings. Optimize code/interface (SPI/I2C), ensure correct rail-to-rail voltage compatibility.

Prototyping Tip: Validate advanced configurations with NextPCB's Quick-Turn Proto PCB Service.

Conclusion: Precision Wiring for Optimal Circuit Control

Potentiometers are fundamental components offering versatile control in countless electronic designs. Understanding their types, selection criteria, and, critically, mastering proper wiring techniques is non-negotiable for achieving reliable performance and avoiding costly failures or recalibration. By applying the voltage divider principles, utilizing wiring diagrams accurately, avoiding common pitfalls, and considering advanced techniques like shielded wiring or buffering where needed, you ensure your potentiometer-controlled circuits function flawlessly.

Whether you're building audio gear, calibrating instrumentation, or designing industrial controls, robust potentiometer wiring underpins success.