Support Team

Feedback:

support@nextpcb.comRegularly, when an equipment developer a PCB, he thinks about the electric signal as well as the design of the elements on the circuit card, concentrating on the feature of the item. Much less factor to consider is provided to PCB production and also set up. To make PCB manufacturing smooth, particularly for SMT setting up, unique interest ought to be paid to PCB setting up the layout.

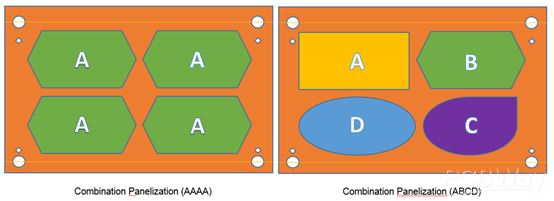

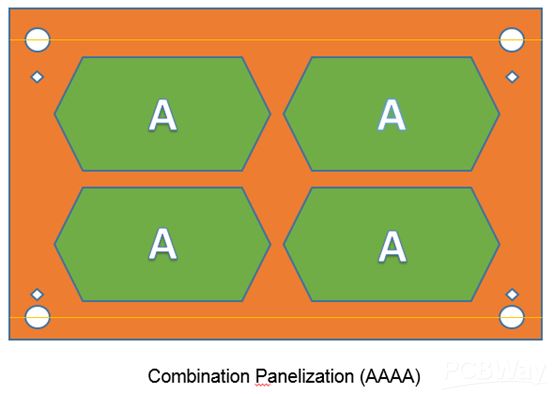

PCB panel is a mix of some PCB device boards with numerous feasible link settings, as received in the numbers listed below.

Nevertheless, this kind of penalization attributes disadvantages also. On one hand, in the process of production line job, item distinction is challenging to take care of, resulting in item turmoil. On the other hand, when one board amongst the mix endures negative high quality or perhaps ditch, the total variety of panelizations will certainly decrease as well as it misbehaves for making removal.

This sort of panelization includes some benefits. To start with, it appropriates for the production version including numerous PCB mixes in items like house home appliances, and also playthings. Second of all, it is beneficial to manufacturing performance enhancement as well as expense reduction to ensure that items turn over and also semi-finished items supply can be substantially lowered, which can conference clients' need of rapid delivery.

Whatever type of PCB, it generally requires to embrace a panel framework. Nonetheless, there are lots of means to make the panels. In some cases, it is hard to identify which method to utilize and also the variety of panels.

Mix panelization (ABCD):

As a typical technique, AAAA mix panelization is one of the most massively used panelization approaches. Great deals of benefits add to its existing leader condition. To start with, this sort of panelization works with all scenarios, without factors to consider to be taken of SMT suppliers construction problems and also item mix. Second of all, order finalization isn't affected by producing number, permitting the optimum variety of panels efficiently based upon the optimum variety of SMT devices to make sure that it causes the highest possible manufacturability amongst all mixes of panelization. Third, publishing high quality will not be lowered because of the impact of pad alignment of unique parts in the process of printing pattern style. Ultimately, running trouble will not be gathered owing to the various positionings of panels in each run of the entire treatment.

Mix panelization (AAAA):.

PCB panels are typically made in several means, such as ABAB, ABCD, or AAAA. It is challenging to generalize which sort of panel is excellent, which requires to be identified by thinking about the thickness and also circulation of elements on the board in addition to the arrangement of devices. All these kinds of panels have their very own benefits and also downsides.

Final thought:

The above is primarily concerning the layouts of inflexible PCB panels. For versatile PCB, the PCB manufacturing setting might be various, as well as the demands of panels will certainly be various. Anyhow, panelization is made to please the need of SMT setting up as well as the safety procedure, after the conclusion of the setting up or to go back to the veneer setting up of completed items, so whether the difficult or soft board, the panel layout need to not just take into consideration the setting up toughness demands, likewise intend to think about the factors of manufacturing after the conclusion of the panel demand, can fulfill these 2 factors, is great panel layout.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now