Stacy Lu

Support Team

Feedback:

support@nextpcb.comKey Takeaways

In modern LED lighting systems, the PCB serves not only as a carrier for electrical connections but also plays a critical role in thermal management. LED light sources convert approximately 70% to 80% of input power into heat. If this heat is not effectively dissipated, it accumulates at the semiconductor junction, leading to reduced light output (lumen depreciation) and potential thermal failure, thereby drastically shortening the lifespan. Therefore, selecting the appropriate PCB substrate based on power density is a core decision for ensuring the long-term reliability of LED systems.

FR4 (Flame Retardant Level 4) is the most common glass-reinforced epoxy laminate in the electronics industry, widely used in standard consumer electronics.

In LED technology, FR4 is typically suitable for applications with low thermal loads, such as small decorative lights, status indicators, or low-brightness backlight modules. These applications have minimal power requirements and do not demand high-efficiency thermal management.

The primary limitation of FR4 is its low thermal conductivity, approximately 0.25 W/m·K, which is significantly lower than aluminum or copper materials. This restricts its performance in high-power density applications.

To mitigate the thermal limitations of FR4, designers often implement additional thermal management strategies. Thermal Vias are frequently used to transfer heat to a copper plane on the bottom side of the PCB, utilizing a larger copper area for spreading. Additionally, increasing copper weight or using dielectric materials with slightly higher thermal conductivity are common practices.

While FR4 offers cost advantages and multi-layer routing flexibility, it is generally insufficient for single LEDs exceeding 1 W without aggressive thermal design. High-power LEDs require more efficient heat dissipation paths to maintain junction temperatures within safe limits.

FR4 serves as an economical choice for low-power LED applications due to its cost-effectiveness. However, for high-power density designs, switching to Aluminum or Copper-Core PCBs is necessary to avoid thermal bottlenecks.

With the widespread adoption of LEDs, Aluminum-based PCBs (also known as Metal Core PCBs, or MCPCBs) have become the preferred solution for balancing performance, cost, and reliability in commercial lighting, street lighting, and indoor fixtures.

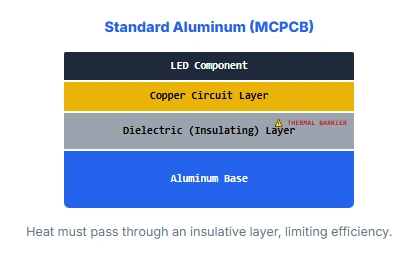

Aluminum PCBs typically consist of three main layers:

Aluminum PCBs are the standard for office lighting, streetlights, and most residential fixtures. Their balance of thermal performance and cost-effectiveness makes them the default choice for volume production.

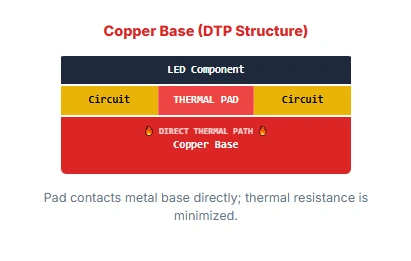

For applications with extreme thermal loads and high-reliability requirements—such as automotive LED headlights, high-bay lighting, and UV curing equipment—Copper-Core PCBs are often utilized. These frequently employ Direct Thermal Path (DTP) technology or Direct Bonded Copper (DBC) substrates.

While Copper-Core solutions are heavier and more expensive to manufacture, their performance is irreplaceable in extreme environments. They provide the necessary thermal headroom to run LEDs at their maximum potential without compromising lifespan.

Copper-Core PCBs, particularly those with DTP technology, are the ultimate solution for extreme power density. They justify their higher cost by delivering unmatched reliability for critical high-power applications.

Choosing the right PCB substrate is a balancing act between thermal simulation data and budget.

At NextPCB, we provide precision manufacturing for all substrate types and offer rigorous DFM (Design for Manufacturing) checks to optimize your stack-up. Whether you need cost-effective aluminum boards or high-performance copper-core technology, ensuring material consistency and tight tolerances is our commitment to your product's success.

More Substrate Comparison Articles:

Technical Support & Quote:

If you are selecting substrates for your LED project, visit our Advanced PCB Quote Page for detailed specifications and pricing on Aluminum or Copper-Core PCBs.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now