Introduction

In high-power electronics, thermal management is a critical design constraint that directly impacts system reliability and MTBF (Mean Time Between Failures). As power densities increase in electric vehicle (EV) powertrains, industrial IGBT modules, and high-intensity LEDs, traditional organic substrates often reach their physical limits.

Selecting the optimal substrate requires an objective evaluation of Metal-Core PCBs (IMS) and Ceramic Substrates. This guide analyzes the technical trade-offs and application boundaries for these materials in high-performance environments.

- Table of Contents

- 1. The Baseline: Thermal Limitations of FR4

- 2. Metal-Core PCB (IMS/MCPCB): Scalable Heat Dissipation

- 3. High Thermal Conductivity Solutions: Ceramic Substrates

- 4. Technical Comparison Summary

- 5. Substrate Selection Guides

- 6. NextPCB's Manufacturing Capabilities

- Conclusion

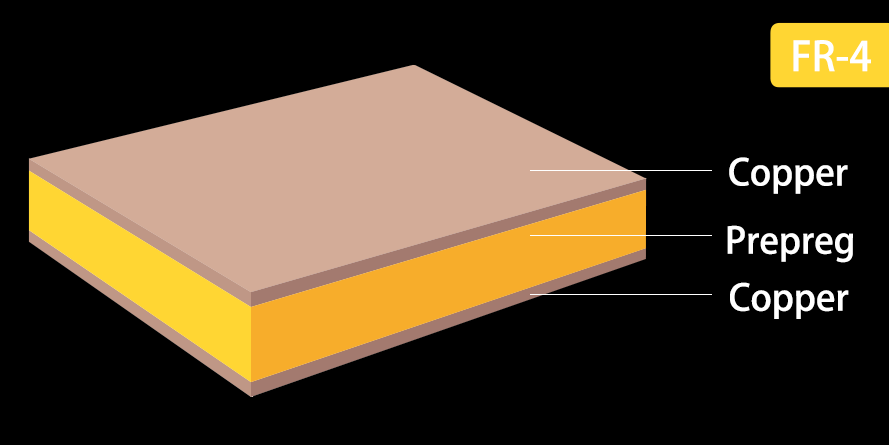

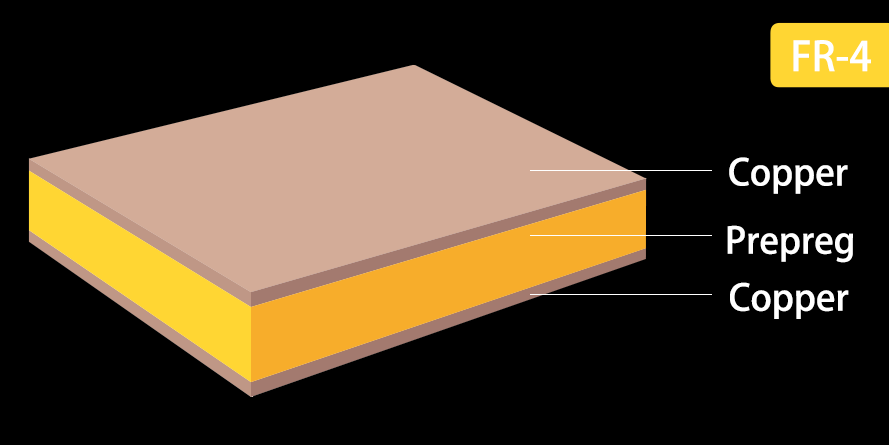

1. The Baseline: Thermal Limitations of FR4

FR4 (Flame Retardant 4) is the industry standard for general-purpose electronics. While cost-effective, its material composition creates significant bottlenecks in high-heat scenarios.

- Thermal Conductivity: Standard FR4 offers a range of approximately 0.2 to 0.5 W/m·K (typically around 0.3 W/m·K). The primary constraint is the high thermal resistance in the Z-axis, which leads to localized heat accumulation near the component junction.

- Operating Stability: While high-Tg FR4 (170°C+) provides better mechanical stability at elevated temperatures, it does not improve heat dissipation rates. Under high heat flux, organic resins are prone to carbonization and reduced dielectric integrity.

Engineering Insight: FR4 remains suitable for control logic and low-power density applications. However, once power dissipation requirements exceed standard convection capabilities, a transition to inorganic or metal-based cores is necessary.

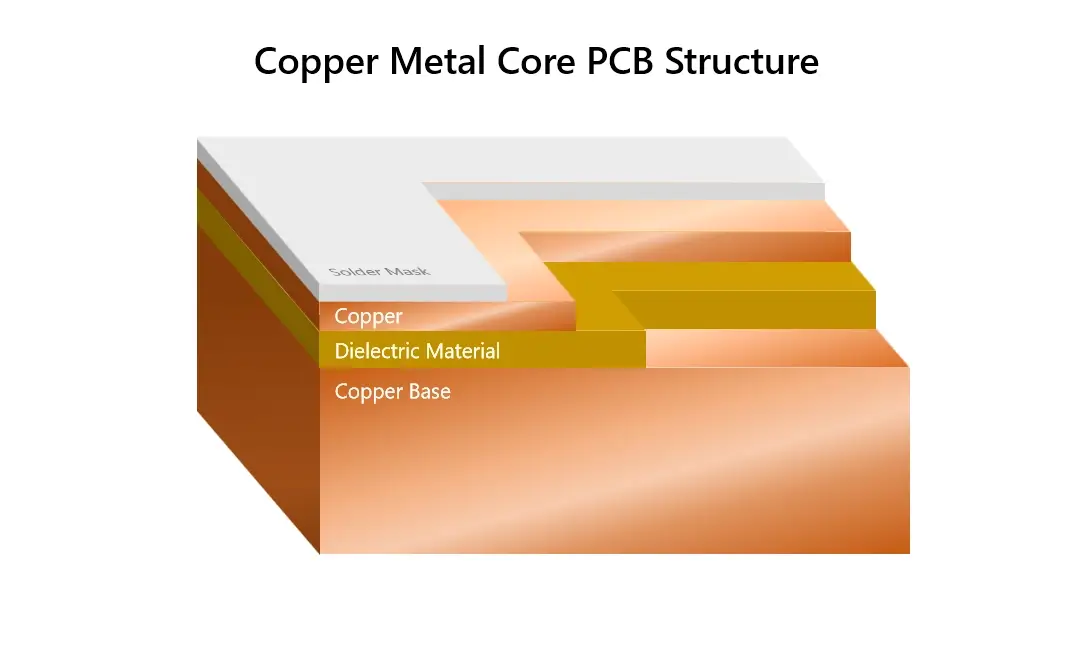

2. Metal-Core PCB (IMS/MCPCB): Scalable Heat Dissipation

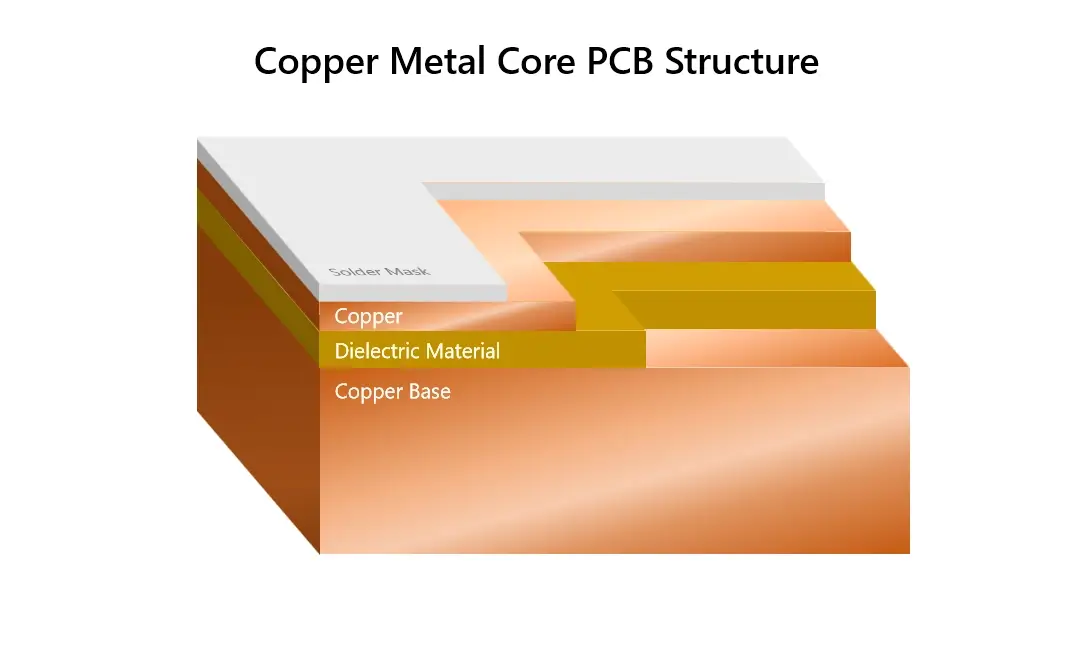

Insulated Metal Substrates (IMS), or Metal-Core PCBs, replace the epoxy-glass core with a metal heat spreader (typically Aluminum or Copper) to enhance heat transfer.

Structure and Thermal Resistance

An IMS consists of a metal base, a circuit layer, and a thin, thermally conductive dielectric layer.

- The Dielectric Interface: The total thermal resistance (Rth) of an IMS is dominated by the dielectric layer, governed by the ratio t/k (thickness over thermal conductivity).

- Performance Range: NextPCB offers a versatile range of dielectric system options with thermal conductivities typically ranging from 1.0 to 10.0 W/m·K. Design engineers must balance dielectric thickness for electrical isolation against the need for a short thermal path.

Material Variants

- Aluminum Base: The most common IMS due to its balance of thermal performance and cost. It utilizes aluminum variants such as 1001, 3001, 5052, and 6063. It is widely used in LED PCBs.

- Copper Base: Used in premium Copper-Core PCBs. While copper provides higher bulk conductivity (∼390 W/m·K), its application is generally reserved for extremely high localized heat loads.

3. High Thermal Conductivity Solutions: Ceramic Substrates

For applications where organic dielectrics cannot meet thermal or reliability constraints, Ceramic Substrates (often categorized as Ceramic PCBs) offer a fundamental material shift. These include DPC (Direct Plated Copper) and DBC (Direct Bonded Copper) technologies.

Material Properties and CTE Matching

Ceramics eliminate the need for an organic polymer interface, providing a direct, inorganic thermal path.

- 1) Alumina (Al2O3, 96% & 99%): Provides 24–30 W/m·K with a CTE of 4.5–8.0 ppm/°C. It is a stable and cost-effective inorganic solution for general power modules.

- 2) Aluminum Nitride (AlN): Features superior engineering-grade conductivity (NextPCB supports ≥ 170 / ≥ 230 W/m·K optional grades). Its CTE (2.0–3.5 ppm/°C) more closely matches Silicon (∼2.6 ppm/°C) than Alumina or Metals.

- 3) Reliability: Superior CTE matching minimizes interfacial stress and solder joint fatigue during repetitive thermal cycling, which is critical for bare-die mounting.

Note: Values vary by material grade, thickness, and boundary conditions; use them as engineering ranges and confirm with NextPCB fab DFM for specific designs.

4. Technical Comparison Summary

| Feature |

FR4 |

Metal-Core (IMS/MCPCB) |

Ceramic Substrate (AlN/Al2O3) |

| Thermal Conductivity |

0.2 – 0.5 W/m·K |

1.0 – 10.0 W/m·K (Dielectric) |

24 – 230 W/m·K (Bulk) |

| CTE (ppm/°C) |

14 – 17 (Poor) |

23 (Al) / 17 (Cu) |

2.0 – 8.0 (Excellent) |

| Dielectric Path |

Organic Resin |

Polymer Thin-film |

Inorganic Ceramic |

| Moisture Absorption |

Can absorb moisture |

Minor absorption (laminate) |

Effectively non-hygroscopic |

| Copper Thickness |

0.5 – 3 oz |

0.5 – 4 oz (Std); Up to 8 oz |

1 – 1000 μm (∼30 oz) |

| Primary Application |

Control circuits |

Standard LEDs, PSUs |

IGBT, EV, RF, CPV |

5. Substrate Selection Guides

High-Density LED & UVC Systems

When heat flux exceeds 10W/cm2, the thermal resistance of polymer dielectrics may lead to junction overheating.

- Selection: Alumina or AlN Ceramic PCBs are preferred to prevent wavelength shifts and maintain luminosity stability over time.

EV Powertrains & IGBT Modules

High-voltage isolation (>800V) and severe thermal cycling require materials with high dielectric strength and mechanical stability.

- Selection: DBC Ceramic Substrates. These provide the durability to withstand delamination risks associated with high-current power switching and heavy copper requirements (commonly up to 10 oz).

6. NextPCB's Manufacturing Capabilities

NextPCB provides thermal management solutions tailored to specific engineering constraints. For detailed technical specs, please refer to our Ceramic PCBs Capabilities.

- IMS (Metal-Core) Production:

- - Substrates: Aluminum (variants such as 1001, 3001, 5052, 6063) and Copper.

- - Thermal Conductivity: 1.0W to 10.0W/m·K.

- - Copper Weight: 0.5oz to 4oz (Standard); higher weights available up to 8oz (subject to DFM).

- - Min Trace/Space: 5/5 mil (Standard); 4/4 mil available for specific material/stack-up combinations.

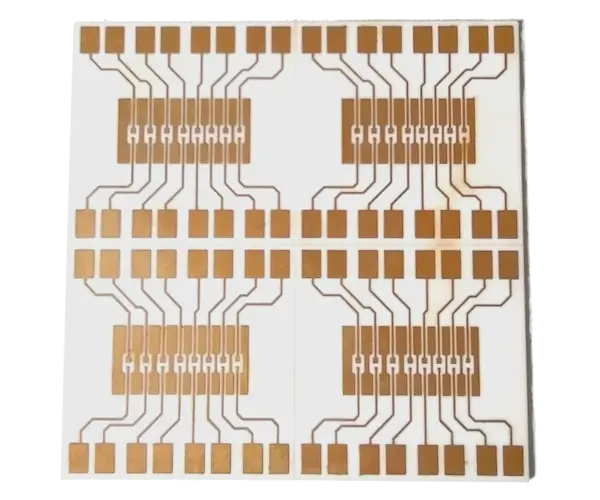

- Ceramic Substrate Fabrication:

- - Materials: Alumina (Al2O3 96%/99%) and Aluminum Nitride (AlN ≥ 170 / ≥ 230 W/m·K grades).

- - Max Dimensions: 120 × 120 mm.

- - Technologies: DPC (Precision trace down to 2/2 mil / 0.05mm) and DBC (commonly used for heavy copper designs up to 10oz). Overall copper thickness ranges from 1–1000 μm (∼30 oz) depending on structure and process.

- - Surface Finishes: ENIG, ENEPIG, Immersion Silver, and OSP.

- Quality Assurance: AOI, Flying Probe Testing, and reliability testing options (e.g., Thermal Shock) available per program requirements.

Conclusion

The transition from FR4 to IMS or Ceramic substrates is driven by power density and reliability requirements. While IMS is a scalable solution for general thermal needs, Ceramic Substrates are the preferred choice for mission-critical, high-voltage, and extreme heat-flux applications where CTE matching and bulk conductivity are paramount.

- >> Explore Ceramic PCB Manufacturing Capabilities

- >> Copper Core PCB Manufacturing Capabilities

- >> Aluminum PCB Manufacturing Capabilities

Advanced PCB Capabilities Advanced PCB Quote PCB Assembly Quote

About the Author

With extensive experience in the PCB and PCBA industry, Stacy has established herself as a professional and dedicated Key Account Manager with an outstanding reputation. She excels at deeply understanding client needs, delivering effective and high-quality communication. Renowned for her meticulousness and reliability, Stacy is skilled at resolving client issues and fully supporting their business objectives.