Military and defense PCBs usually have higher standards than ordinary PCBs because their role is vital and they will withstand such harsh conditions. Military-grade PCB is the strongest, most efficient, and most reliable printed circuit board on the market.

Application and Type of Military PCB

Military PCBs include PCBs used in naval, aviation, defense, and even space applications. Since the military PCBs have so many different application areas, it is important to use multiple PCB types to ensure that military and defense PCBs are suitable for the electronic devices that use them.

Applications using military PCBs include:

• The power supply for AWACS airborne early warning and control system-"Eye in the Sky"

• Auxiliary power supply unit for radar control system

• Radio communication system

• Tower system

• LED lighting system

• Firearms and explosives testing equipment

• Underwater navigation system

• Injection instrument

• Interference system

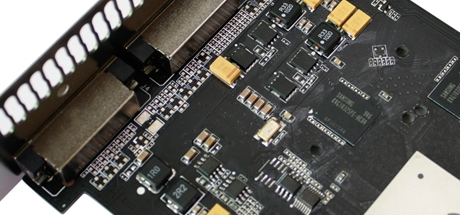

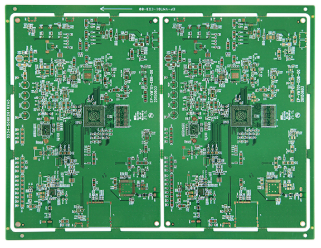

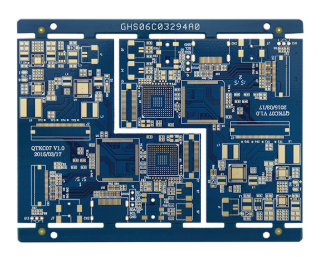

These military PCBs are often subjected to high pressure and high temperature, which means they generally require high-temperature substrates, such as high-temperature laminates, copper, or aluminum. Military PCB manufacturers must produce PCBs that can resist heat-induced oxidation and efficiently dissipate heat with a low-weight design.

NextPCB provides high-quality, long-lasting, heat-resistant PCBs for various military and defense applications. It has passed ISO 9001:2008, QCQ, IATF16949, UL, and RoHS certifications, so you know that you can rely on these PCBs to perform outstanding performance under the harsh conditions required by military equipment. We also produce various types of PCBs for various military and defense applications.

We have invested heavily in introducing advanced automation equipment to improve product performance and ensure product quality.

If your military or defense applications require high-quality PCBs, NextPCB should be your wise and cost-effective choice. Unlike many other PCB manufacturers, we also do PCB assembly, and there is no need to waste time trying to find other assembly suppliers and transport your materials between different locations. We will take care of everything, which means you can get printed circuit boards in a fast lead time and operations can proceed smoothly.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate