Support Team

Feedback:

support@nextpcb.comNextPCB Vocabulary

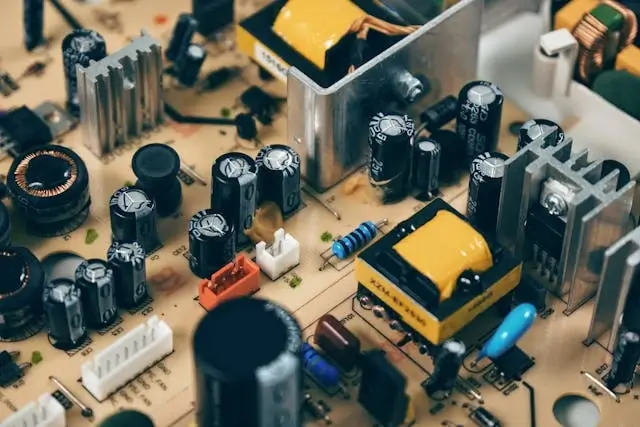

Definition: Through-hole assembly is the process of mounting leaded components by inserting their leads through drilled holes in a PCB and soldering them on the opposite side. It remains valuable where mechanical strength, high current, heat tolerance, or field serviceability are priorities, and it often coexists with SMT on mixed-technology boards.

Choose through-hole for connectors, large electrolytics, relays, transformers, switches, and other parts that see mechanical stress or carry power. Leads passing through the board create robust joints less prone to dislodging during handling or vibration, and many through-hole parts dissipate heat better than comparable SMT versions.

There are four mainstream ways to solder through-hole parts. Hand soldering is flexible for prototypes and rework. Wave soldering drives high throughput on through-hole-heavy or one-sided mixed boards. Selective soldering uses programmable mini-waves to solder individual pins near SMT parts without disturbing nearby reflowed joints, and nitrogen atmospheres further improve wetting and reliability. Pin-in-paste, also called through-hole reflow or intrusive soldering, prints solder paste at the plated holes, inserts the leads, and solders everything in the reflow oven together with SMT.

Most through-hole components are either axial, with leads exiting opposite ends, or radial, with both leads on one side. Axial parts allow flexible lead spacing but consume more board length; radial parts stand off the board and can pack more densely. Dual-inline packages and other leaded ICs are also standard in legacy or ruggedized designs.

Sizing the hole, pad, and annular ring correctly is critical. As a rule of thumb, minimum hole size equals the maximum lead diameter plus 0.25 mm for density level A, 0.20 mm for level B, or 0.15 mm for level C. IPC-2221 defines pad diameter as minimum hole size plus twice the minimum annular ring plus a standard fabrication allowance. Provide about 4 mil solder-mask relief, and remember that tight hole-to-lead clearances can slow assembly or require soldering from both sides.

Aim for sound barrel fill and smooth, concave fillets that wet both pin and pad. While 100 percent fill is ideal for many classes, 75 percent barrel fill is typically acceptable for IPC Class 2 and Class 3, provided wetting and geometry meet criteria. Document polarity and orientation, specify any height restrictions, and include special notes for connectors. Use AOI where practical, and escalate to X-ray or cross-section for failure analysis.

Selective soldering is a staple when only a few through-hole parts remain on a densely populated SMT board. The system fluxes each joint, then brings a localized solder fountain to the programmed location, producing repeatable, production-grade joints without masking SMT areas. Nitrogen-enhanced systems reduce oxidation and help ensure long-term reliability.

Pin-in-paste lets you solder THT pins during the same reflow cycle as SMT, eliminating a secondary wave or selective step. Paste is printed around or into the plated holes via stencil apertures, parts are inserted, and reflow wicks molten solder through the barrel to form the fillet. It's most effective when only a handful of THT parts are present; otherwise wave or selective may be more economical.

Mount flatter, shorter components first, then taller ones; keep adequate keepouts for selective nozzles; and bend or clinch leads above the soldered area to reduce heat and solder demand. For high-current or heavy parts, consider mechanical support or potting after test, and specify conformal coating where the environment demands it.

Through-hole assembly trades density and drilling cost for greater mechanical strength, easier field repair, and higher power handling, while SMT assembly maximizes automation, miniaturization, and routing freedom. Many products blend both to balance reliability, cost, and size.

Ready to build rugged, high-reliability THT or mixed-technology boards?

Get a free DFM/DFA review and a fast quote with NextPCB's Turnkey PCB Assembly - with AOI, X-ray, and functional testing available.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now