Support Team

Feedback:

support@nextpcb.comNextPCB Vocabulary

Surface‑mount technology (SMT) is a highly automated and efficient method for attaching electronic components directly onto the surface of printed circuit boards (PCBs) using solder paste and reflow soldering. SMT assembly capabilities encompass the full spectrum of processes, machinery, and inspection systems that collectively ensure high‑quality, reliable PCB assembly from prototypes to high‑volume production.

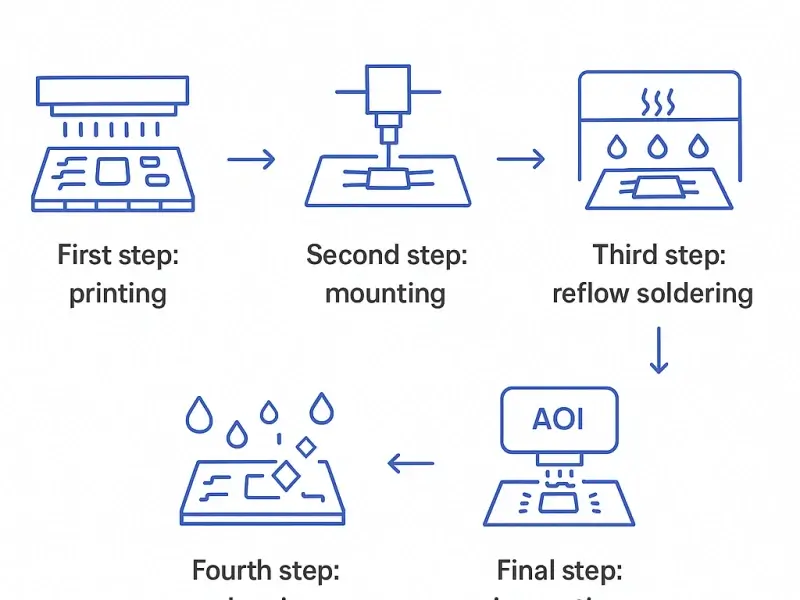

At its core, SMT assembly capability starts with precise solder paste application. A stencil printer deposits a controlled amount of solder paste onto designated solder pads on the PCB. The consistency of paste volume, the effectiveness of the squeegee angle and speed, and the proper storage and handling of paste are critical to avoid defects. Solder paste inspection (SPI), often using 2D or 3D vision systems, further improves yield by detecting printing defects before placement.

Component placement is performed by pick‑and‑place machines that vary in speed and accuracy. High‑speed “chip shooters” can place thousands of simple passive components per hour, while precision placers handle complex or large parts using gantry systems, vision alignment, and sub‑millimeter accuracy. These machines rely on diverse feeders (tape‑and‑reel, stick, tray, bulk, direct die) to supply components efficiently.

Following placement, boards advance into the reflow soldering oven. Controlled thermal profiles gradually heat assemblies, melt the solder paste, and allow surface tension to self‑align components into correct positions. Common heating methods include convection and infrared, with variations like vapor‑phase or hybrid heating systems used based on specific manufacturing requirements.

Quality assurance is integral. Automated optical inspection (AOI) verifies component presence, placement accuracy, solder defects, and polarity issues. More advanced assembly lines may include in‑circuit testing (ICT), functional testing, X‑ray inspection for hidden solder joints (e.g., in BGA packages), and even four‑stage inspections including solder paste inspection (SPI), AOI, ICT, and final visual checks.

SMT assembly capability also includes flexibility in production modes. Systems must support everything from one‑off prototypes to large volume runs (10k+ units), with express turnarounds (24 h) or standard schedules (up to 7 days) depending on component sourcing and complexity. Turnkey assembly services simplify logistics by handling both component procurement and assembly, whereas partial or consignment options allow hybrid workflows.

Comparing with Through Hole Technology (THT), the advantages of robust SMT assembly capabilities include miniaturization, weight reduction, improved electrical performance, and manufacturing efficiency. SMT enables placement of components on both PCB sides, higher component densities, lower cost, better mechanical resilience, reduced inductance, improved EMC performance, and fewer drilled holes.

In practice, proven SMT capabilities require ISO‑certified processes, proprietary placement libraries refined by millions of component placements, and rigorous process control to deliver reliable outcomes at scale. The automation and streamlined workflow also enhance first‑run yield—reducing errors and optimizing operator performance.

NextPCB owns a highly automated SMT assembly house with complete PCB assembly abilities. SMT workshop has been assembling SMT designs for nearly ten years. The advanced equipment, highly trained PCB engineers, and strictly quality control system form an experienced SMT assembly team. Our completely computerized SMT production line allows the achievement of extremely high accuracy and high throughput. Manual production is also available for the complex parts, small-batch, or prototype products.

Recommend Reading: PCB Assembly - The Most Comprehensive Guide | NextPCB

Except for the types mentioned above, NextPCB also provides various other small chip packages that have a pitch of 0.2mm or larger. Our PCB assembly process will be carefully matched to your PCB design and specific requirements. When you choose us, you only need to focus on your design but do not have to think about the details of production. NEXPCB can satisfy all the requirements in your SMT prototype PCB assembly or low-volume PCB production.

CTA: Submit Your Gerber Files for a Customized SMT Quote

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now