Support Team

Feedback:

support@nextpcb.comFor many engineers, the PCB workflow looks straightforward:

In practice, however, the success of a PCB build is often decided before the order is placed—long before copper is etched or holes are drilled. It happens at a stage that is frequently underestimated: DFM (Design for Manufacturability).

As PCB designs become denser, faster, and more cost-sensitive, DFM is no longer an optional "extra check." It has become a key interface between design intent and manufacturing reality.

So, what are the key steps involved in the process from a design draft to final production? We will analyze this from three dimensions: Gerber file, DFM software inspection, and CAM engineers review.

From an engineering perspective, exporting Gerber files feels like finishing the job.

From a manufacturer's perspective, however, Gerber files represent something very different.

They contain:

In other words, Gerber files are manufacturing instructions, not design documentation. They describe what to fabricate, but not why it was designed that way. This distinction matters, because manufacturing decisions will be made without knowledge of your design assumptions—unless potential issues are addressed earlier.

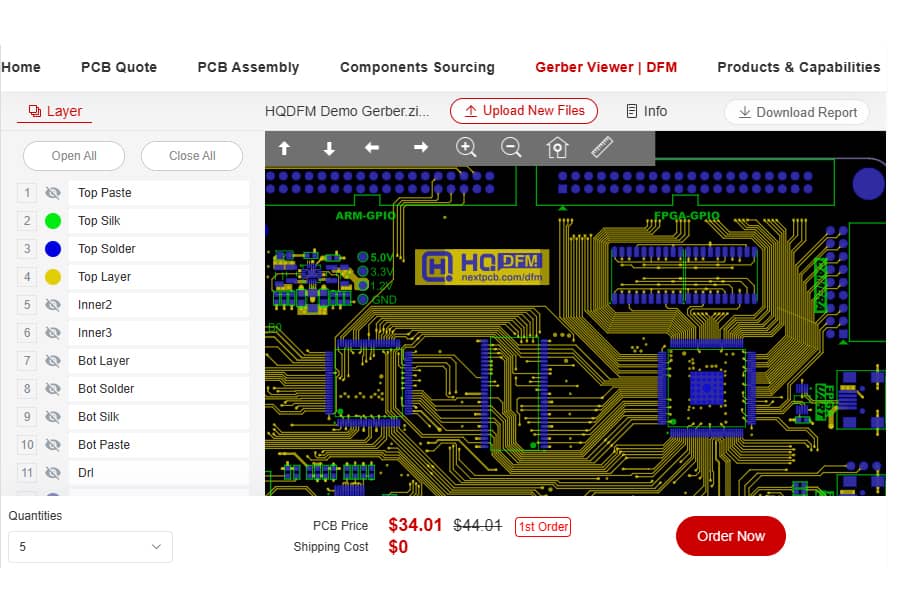

Free Gerber Viewer Online

View Your Gerber Files Online for Free

Many engineers rely on the PCB manufacturer's CAM department to catch problems:

CAM engineers are highly skilled, but their objective is fundamentally different from that of a design engineer.

CAM engineering focuses on:

Design engineering focuses on:

When a manufacturability issue is discovered only at the CAM stage, the solution tends to favor production robustness, not design optimization.

Typical CAM-side adjustments may include:

These changes often make the board easier to manufacture, but they may also:

Once the design reaches CAM, the opportunity to make informed trade-offs is already limited.

CAM engineer is reviewing gerber file

DFM tools exist to solve a very specific problem:

Instead of discovering issues through back-and-forth emails after order submission, DFM allows engineers to evaluate their design against real manufacturing limits before releasing data.

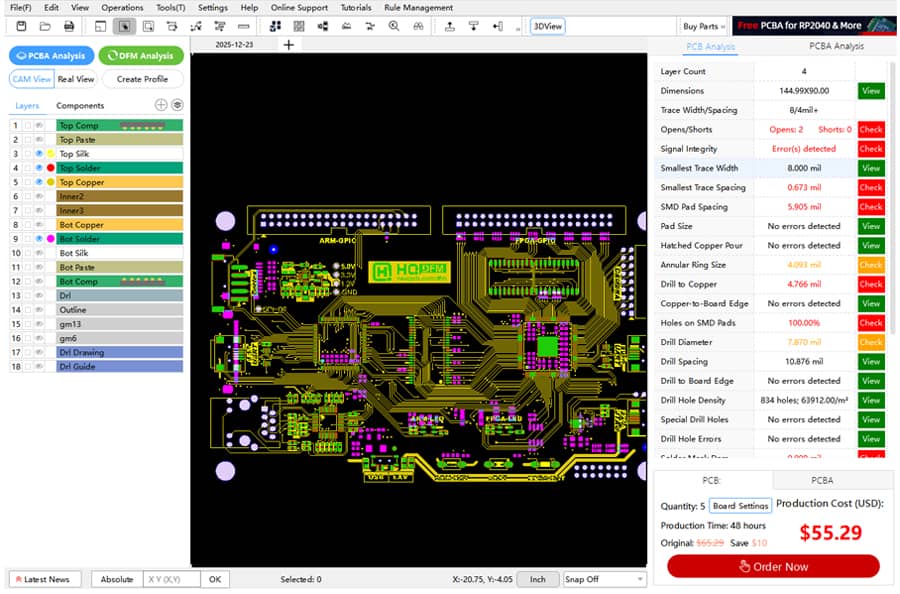

A comprehensive DFM analysis typically covers:

Importantly, DFM does not simply flag “violations.”It highlights risk levels. This distinction is critical. Some parameters may be technically manufacturable but:

DFM provides visibility into these trade-offs early—when adjustments are inexpensive and intentional.

HQDFM tool appearance - Free for everyone

From the manufacturer's side, DFM-ready designs have a measurable impact. When incoming data has already passed a realistic DFM review:

This leads to:

In contrast, designs that rely entirely on CAM-stage corrections tend to:

For this reason, many advanced PCB manufacturers actively encourage customers to run DFM checks aligned with their process capabilities. Not because it shifts responsibility—but because it improves outcomes for both sides.

One of the most overlooked benefits of DFM is its role in scalability. A PCB that works as a prototype is not necessarily ready for volume production.

Common examples include:

These issues may not cause immediate failure in small batches, but they often become sources of variation at scale.

DFM helps identify:

This makes DFM not just a manufacturing check, but a production-readiness assessment.

In a modern PCB supply chain, value is no longer defined solely by price or speed. High-quality PCB services increasingly differentiate themselves by:

When DFM tools and PCB manufacturing services are aligned, engineers gain:

The result is not just a finished PCB—but a smoother path from design to deployment.

As PCB designs push tighter tolerances and higher complexity, relying on downstream corrections is becoming increasingly risky.

DFM is not an extra step added to the workflow. It is a shift in where engineering decisions are made. By addressing manufacturability at the design stage:

In that sense, DFM is not about making designs "easier" for factories. It is about making designs ready for reality.

Get Your Designs Viewed & Quote Online Get Free DFM Software

You may also be interest in....

> HQDFM PCB Design Analysis Tool User Manual

> PCB Assembly - The Most Comprehensive Guide | NextPCB

> NextPCB Quality Control Process

> How NextPCB ensures your product quality: Four Core Test Reports

> NextPCB Multi-Design Ordering Specification: Different PCB Designs in Gerber Files

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now