Support Team

Feedback:

support@nextpcb.comBall Grid Array PCB Manufacturing: Design, Process & Quality Control

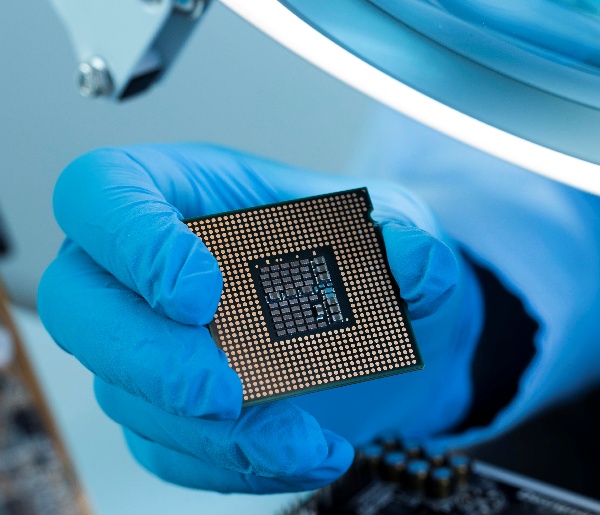

Ball Grid Array (BGA) technology revolutionized electronics manufacturing by enabling the dense, high-performance devices powering our world. At NextPCB, we've refined BGA assembly to deliver unparalleled reliability in complex applications – from micro-BGAs in wearables to large ceramic BGAs in aerospace. Here's your comprehensive roadmap to mastering this critical process.

Core Principle:

BGAs replace fragile leads with solder ball arrays underneath the package. This design delivers:

Top 9 Most Common IC Packaging Types in Modern Electronics

(Per IPC-7095E Standards)

|

Type |

Name |

Key Properties |

Best Applications |

|

P-BGA |

Plastic BGA |

Cost-effective, moisture-sensitive |

Consumer devices, routers |

|

F-BGA |

Flip-Chip BGA |

Ultra-thin profile, fine pitch (<0.5mm) |

Smartphones, micro-BGA packages |

|

C-BGA |

Ceramic BGA |

Extreme thermal/mechanical resilience |

Automotive, aerospace |

|

T-BGA |

Tape BGA |

Flexible interconnects |

Medical sensors, wearables |

1. Hidden Joints: 100% X-ray

2. Moisture Sensitivity: MSL 2-3 components require:

3. CTE Mismatch: Dynamic warpage during reflow → non-wet opens/cracks

4. Stress Fractures: Corner balls fail first → avoid placement near:

PCB Treatment:

Component Prep:

|

Parameter |

Standard BGA |

Micro-BGA |

|

Solder Paste |

Type 4 (20-25μm) |

Type 5 (10-15μm) |

|

Stencil Ratio |

1:1 |

0.85:1 (Nano-coated) |

|

Placement Accuracy |

±30μm |

±15μm |

|

Vision System |

2D Alignment |

3D Laser Scanning |

1. AOI: Checks coplanarity (±50μm) and misalignment

2. AXI: Detects:

3. Boundary Scan: Electrical validation

4. Acoustic Microscopy: Delamination analysis

|

Failure Mode |

Detection Method |

Prevention Strategy |

|

Non-Wet Opens (NWO) |

Cross-section SEM |

Optimize flux activity temperature |

|

Solder Ball Cracks |

Dye-and-Pry Test |

Corner underfill application |

|

Pad Cratering |

TDR Testing |

Low-CTE PCB materials |

|

Popcorning (MSD) |

CSAM (C-Mode Scanning) |

Strict moisture floor life control |

NextPCB's Roadmap for Next-Gen BGA Solutions:

Get Real-Time Pricing: Click for Instant BGA Online Assembly Quote

Q1: How accurate are NextPCB's online BGA assembly quotes?

Our online quoting system factors in real-time material costs, IPC class specifications, and project complexity. Most quotes are highly accurate and remain valid for 30 days. For projects involving complex layouts or special process requirements, we recommend consulting our engineering team to confirm final pricing.

Q2: What's the minimum BGA pitch NextPCB supports?

We support BGA packages with a minimum pitch of 0.25 mm, including 100% X-ray inspection for all BGA solder joints. If your design requires finer pitch (e.g., 0.20 mm), please contact our engineering team for feasibility assessment.

Q3: Can you repair cracked BGA solder joints caused by thermal cycling?

Yes. We provide professional BGA rework services using precision rework stations and X-ray verification. If your repair process requires underfill injection or Scanning Acoustic Microscopy (SAM), please consult us to evaluate custom solutions.

Q4: How does BGA vs QFN assembly affect signal integrity?

BGA packages offer significantly lower parasitic inductance (<0.1 nH), making them ideal for RF and high-speed digital applications above 800 MHz. QFN packages are more suitable for simpler designs where visual inspection and lower cost are priorities. For GHz-level performance, we generally recommend BGA.

Q5: What level of IPC-7095E compliance do you offer for BGA assembly?

We support full IPC-7095E Class 3 assembly standards upon request, including 100% X-ray inspection, void control, and traceability under ISO 9001 quality management. If you require specific voiding thresholds (e.g., ≤5%), please indicate this in your RFQ for confirmation.

Q6: Can you integrate soldered cold plates in BGA assemblies with thermal resistance ≤0.15 °C/W?

At present, soldered cold-plate integration is not part of our standard service offering. If your project requires integrated thermal management (e.g., bonded copper plates, thermal interface materials), please provide detailed mechanical and thermal specifications for evaluation.

You may also interested in:

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now