Support Team

Feedback:

support@nextpcb.comWhen selecting a PCB (Printed Circuit Board) manufacturer, many customers find that some suppliers do not clearly offer the UL mark option in their quotes. This phenomenon not only affects customer decision-making but also highlights the different approaches manufacturers take toward quality control and market strategies. Understanding the reasons behind these differences can help customers make more informed decisions and underscores the importance of NextPCB as a reliable UL certified PCB manufacturer, particularly in terms of its advantages with UL certification.

The UL Mark is a widely recognized safety certification symbol issued by Underwriters Laboratories (UL). Essentially, it serves as a public assurance that representative samples of a product have been independently tested and found to meet UL's published, stringent safety and sustainability standards. When a consumer sees the UL Mark on an item, such as an appliance or electronic device, it signifies the manufacturer's deep commitment to safety and confirms that the product has undergone rigorous scientific evaluation to minimize foreseeable risks, such as fire or electric shock, under normal usage conditions.

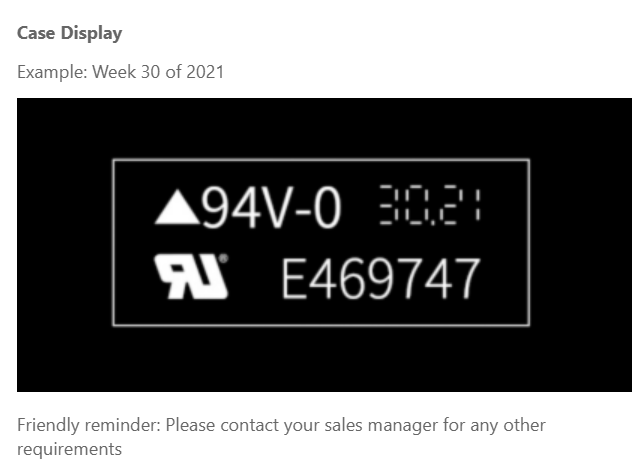

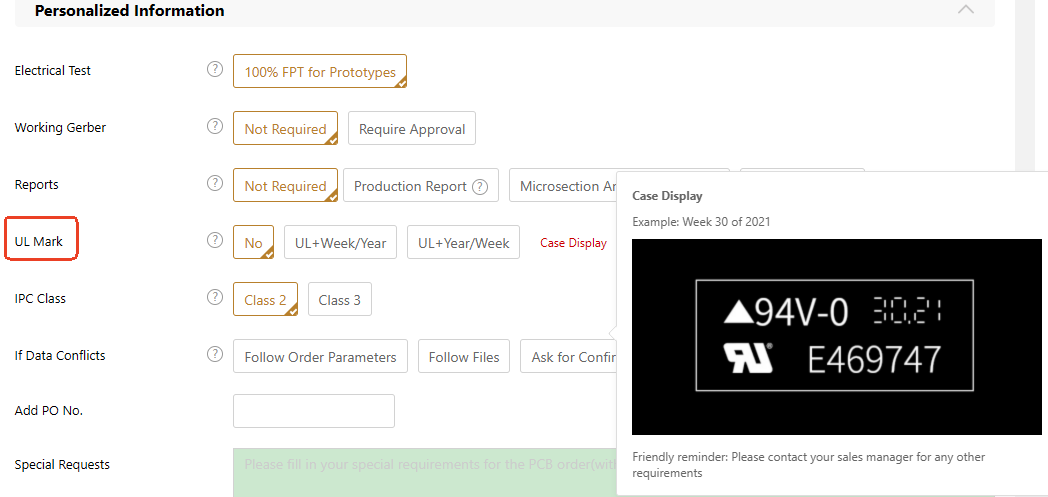

A UL-approved PCB features specific, clearly visible markings on its surface that serve as essential evidence of its compliance and traceability.

These required markings typically include:

These identification elements are crucial for downstream customers and regulatory agencies to verify the PCB's compliance and confirm its source, ensuring the component meets the required safety standards before integration into a final product.

Example: UL mark on PCB

UL certification evaluates Printed Circuit Boards based on a series of rigorous standards. The following three standards are the most critical, focusing on PCB manufacturing processes, performance, and material safety:

UL 796 is the paramount standard focusing on the performance and reliability of the Printed Wiring Board itself. Beyond just fire safety, it covers the PCB's electrical, mechanical, and environmental performance under both normal and abnormal operating conditions.

UL 94 is the internationally recognized benchmark standard for the flame-retardant properties of plastic materials (such as the PCB substrate, FR4). It assesses a material's ability to self-extinguish, its burning rate, and the hazard posed by burning drips, simulating a potential fire scenario.

V-0: Vertical burning stops within 10 seconds, with no burning drips allowed to ignite cotton placed underneath. This is the highest safety rating.

V-1: Vertical burning stops within 30 seconds; dripping is allowed but must not ignite the cotton.

V-2: Vertical burning stops within 30 seconds; dripping is allowed and may ignite the cotton.

This standard focuses on evaluating the long-term performance and electrical insulation characteristics of the polymeric materials used in the PCB (including the substrate, solder mask, and legend/silkscreen inks).

Relative Temperature Index (RTI): Measures the material's stability for long-term operation in high-temperature environments.

Electrical Insulation Properties: Ensures the material's resistance and resilience under electrical stress.

UL certification requires manufacturers to adhere to strict safety standards, including material selection, production processes, and quality control. These requirements make UL certification not only costly, but also technically demanding, involving additional investments and ongoing quality management. For some small- and medium-sized manufacturers, this could mean a significant financial burden and technological challenge. For example, UL testing and maintaining certification status may require additional equipment investments and training expenses.

Different markets and customers have varying needs. In price-driven markets, UL certification may not be a priority, especially when customers are more concerned about cost. In such cases, some manufacturers may choose not to offer UL certification in order to reduce their quotes. While this approach can meet short-term price competition, it could harm long-term market reputation and customer satisfaction.

UL certification is not just a quality and safety mark; it also provides traceability. When issues arise, UL certification helps trace the specific production batch, material sources, and responsible parties. This traceability is especially crucial when dealing with product quality issues or safety incidents. Products without UL certification may face more complicated liability divisions and risk management challenges.

In some high-demand industries, such as aerospace, medical devices, and automotive electronics, UL certification is a basic requirement for market entry. Manufacturers without UL certification may struggle to enter these high-value markets, leading to a decline in brand reputation and market competitiveness. Manufacturers with UL certification can stand out in the competition and gain more customer trust.

As an industry leader, NextPCB is your trusted UL certified PCB manufacturer. We understand the critical importance of high quality and international compliance. That's why our PCB online quote system clearly offers the UL mark option. This not only demonstrates our unwavering commitment to product quality but also provides you with the flexibility to ensure your products meet the world's most rigorous safety standards, allowing them to move freely across markets. Quote online now to customize your UL certified PCBs!

NextPCB's UL identification number is E469747, which can be verified through the UL database, More certifications here.

In conclusion, while other manufacturers may choose not to provide UL certification due to cost, market positioning, or technological barriers, NextPCB always prioritizes customer needs and offers safe, reliable, and globally competitive PCB products. Our online pricing system allows customers to select UL certification services according to their specific requirements, ensuring that every circuit board meets the strictest standards, fully reflecting our responsibility and commitment as an industry leader.

PCB Quote OnlineView NextPCB CatalogView NextPCB Certificates

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now