PCBs made with high glass transition temperature (Tg) materials, typically 170°C and above.

- Enhanced thermal resistance and stability

- Improved mechanical strength at high temperatures

- Reduced thermal expansion

- Better chemical resistance

Support Team

Feedback:

support@nextpcb.comA deep dive into structure, material selection (Aluminum vs. Copper vs. Iron), and design specifications for thermal management in electronics.

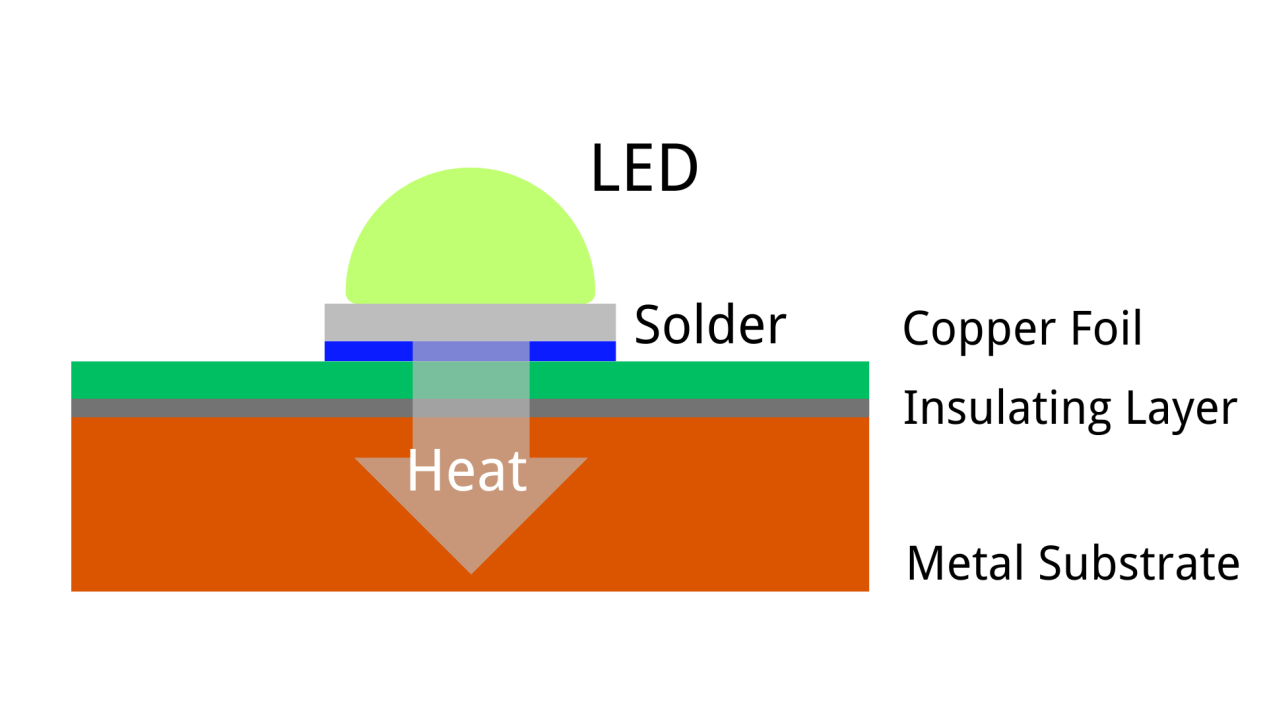

A Metal-Core PCB (MCPCB), also known as a Thermal PCB or Insulated Metal Substrate (IMS), is a type of printed circuit board that incorporates a base metal material as the heat spreader portion of the board. The primary purpose of an MCPCB is to redirect heat away from critical board components (such as LEDs or power transistors) and towards a heat sink or the chassis.

Unlike standard FR4 or CEM1-3 boards which are poor thermal conductors, Metal Core PCBs utilize a base metal—typically Aluminum, Copper, or Steel alloy—to significantly improve thermal management, durability, and dimensional stability.

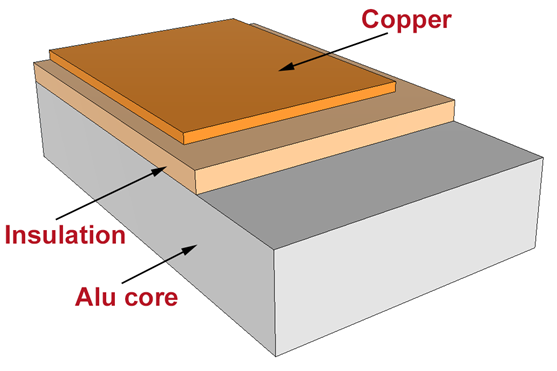

The structure of a Metal Core PCB is a trilayer construct. Understanding these layers is crucial for PCB designers to ensure proper impedance control and thermal conductivity.

Aluminum is the most commonly used material for MCPCBs due to its balance of cost, weight, and thermal performance. It is easier to machine than copper or steel and significantly lighter.

The cost of Aluminum PCBs is primarily driven by:

Copper core PCBs represent the high end of thermal management. While copper is heavier and more expensive than aluminum, its thermal conductivity is far superior (Copper: ~390 W/m·K vs. Aluminum: ~200 W/m·K).

Copper substrates are typically manufactured by overlaying insulating resin and copper foil onto a copper base plate via a hot pressing process. Surface finishes can include immersion gold, silver plating, or OSP (Organic Solderability Preservative).

Similar to aluminum PCBs, there is a dielectric layer between the circuit copper and the base copper. While better than aluminum, the dielectric layer still acts as a thermal bottleneck.

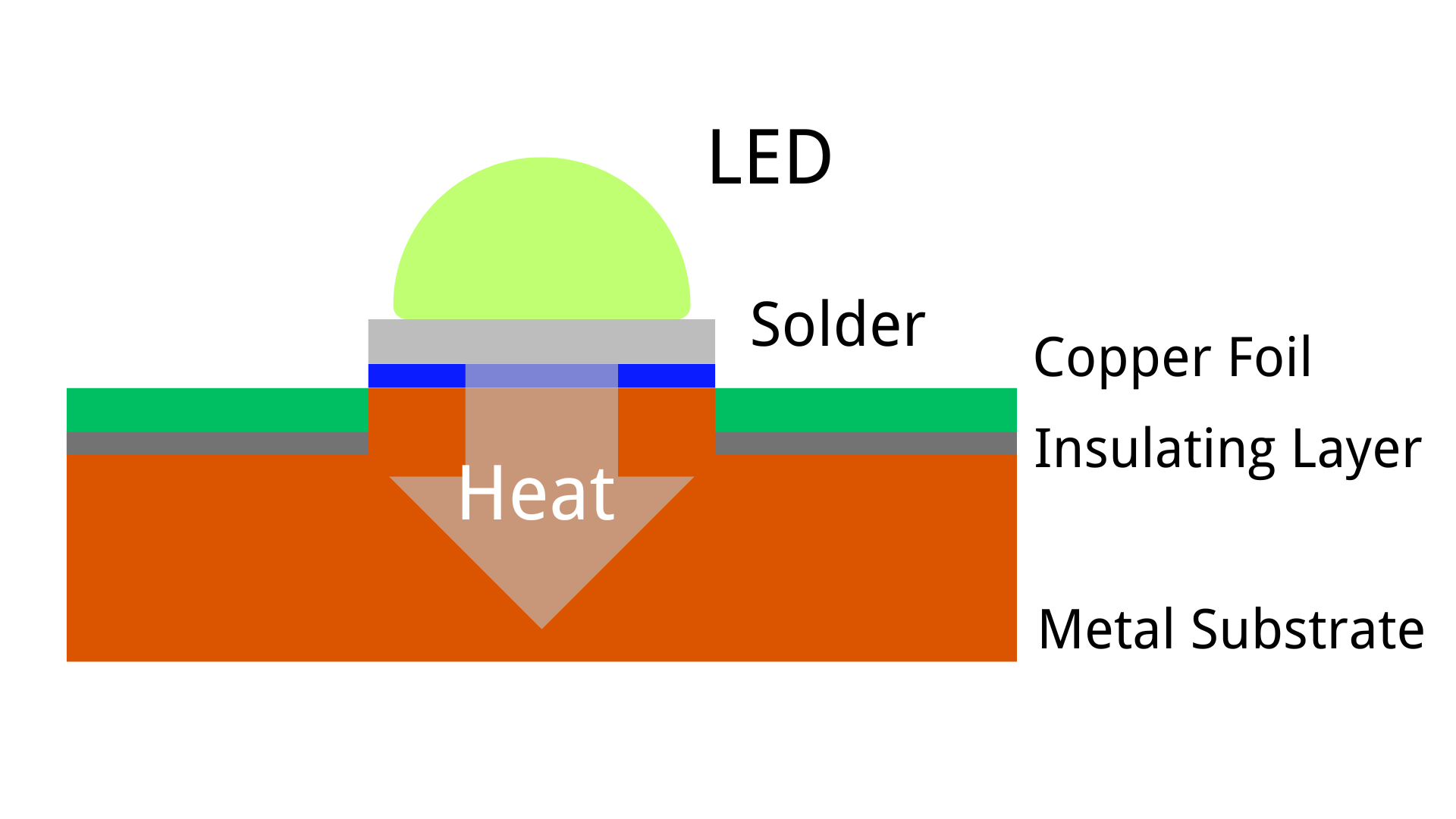

This is a specialized technology primarily used for high-power LEDs (e.g., Automotive Headlights, UV Curing). In this design, the LED thermal pad connects directly to the copper substrate without an insulating layer in between.

Mechanism: The circuit leads are electrically isolated, but the central thermal pad of the component sits directly on the copper base. This minimizes thermal resistance.

Iron-based PCBs (using silicon steel or special steel alloys) replace FR4 or Aluminum in niche applications. The metal thickness usually ranges from 1mm to 6mm.

Iron core PCBs are difficult to manufacture, leading to scarcity in the supply chain:

For procurement managers and engineers, choosing the right substrate is a trade-off between thermal performance, weight, and cost.

| Feature | Aluminum Core | Copper Core | Iron/Steel Core |

|---|---|---|---|

| Thermal Conductivity (Substrate) | Good (~150 - 220 W/m·K) | Excellent (~380 - 400 W/m·K) | Poor (~40 - 60 W/m·K) |

| Cost | Low / Economical | High | Medium (High processing cost) |

| Weight | Light | Heavy | Heavy |

| Shielding | EMI Shielding | EMI Shielding | EMI + Magnetic Shielding |

| Primary Application | General LED Lighting, Audio Equipment | High-Power Automotive LEDs, CPU/GPU | Motors, Dynamos |

When requesting a quote (RFQ) or designing a Metal Core PCB, the following specifications must be clearly defined to ensure manufacturability and performance.

Metal Core PCBs are the backbone of modern high-power electronics, providing the necessary thermal management to ensure device longevity and efficiency. While Aluminum remains the most versatile and cost-effective choice for general lighting and power applications, Copper offers unmatched performance for demanding automotive and industrial use cases. Iron substrates fill a vital niche where mechanical rigidity and magnetic shielding are paramount. By understanding the unique properties of each material and specifying the correct dielectric parameters, designers can optimize their products for both performance and manufacturability.

Get Your Metal Core PCB Quote

Ready to bring your thermal management designs to life with NextPCB? Whether you need a quick-turn Aluminum prototype or a complex Thermoelectric Separation Copper substrate, selecting the right manufacturing partner is crucial. Ensure your files are ready and your specifications are clear to avoid delays.

Contact us today to discuss your project requirements, upload your Gerber files, and receive a competitive quote tailored to your specific thermal needs.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now