Julia Wu - Senior Sales Engineer at NextPCB.com

Support Team

Feedback:

support@nextpcb.comBy NextPCB Technical Team | Updated: 2026

In the world of hardware development, the Printed Circuit Board (PCB) is the brain, but the cable assembly is the nervous system. A common oversight in PCB manufacturing projects is treating cabling as an afterthought. This often leads to integration failures, signal integrity issues, or costly delays during final assembly.

Whether you are sourcing a quick turn PCB for a prototype or planning high-volume production, understanding the engineering behind cable assemblies is critical. This guide covers the definitions, manufacturing standards, and design considerations you need to know in 2026.

A cable assembly is a group of wires or cables arranged into a single unit to transmit power or information. Unlike a loose collection of wires, an assembly is covered by an exterior sheath—typically rubber, vinyl, or shrink-wrapped thermoplastic—that protects the interior conductors from the environment.

While often used interchangeably with "wire harness," there is a technical distinction important for procurement:

For engineers focusing on turnkey PCB projects, specifying the correct type ensures your product passes safety certifications (UL, CE) and withstands its operating environment.

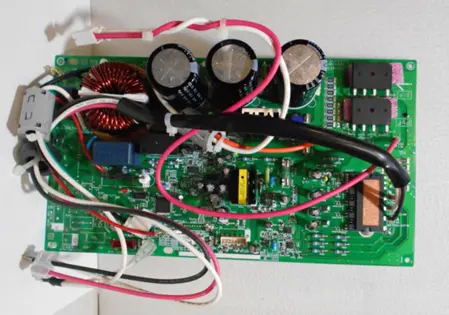

Figure 1: Custom cable assembly designed for secure signal transmission.

To ensure your low cost PCB project doesn't fail due to a cheap cable, you must select the right components. A robust cable assembly consists of three main layers:

The core wire carrying the current. In 2026, pure copper remains standard, but applications requiring high flexibility may use stranded tinned copper. Engineers must calculate the correct American Wire Gauge (AWG) to handle the current load without overheating.

The material choice here dictates the cable's survival:

This is where the cable meets the PCBA. Common types include crimp-style (Molex/JST), soldered cups (DB9), or IDC (Insulation Displacement Connectors). The trend in 2026 is moving towards locking connectors (like JST-GH) to prevent disconnection during vibration.

Design for Manufacturing (DFM) applies to cables just as much as it does to PCB manufacturing. When designing your assembly, consider these four pillars:

Where will the cable live? If it is exposed to sunlight, UV-resistant black jackets are mandatory. If it is used in automotive or medical settings, resistance to oil, chemicals, and sterilization fluids must be specified. Failure to define this can lead to jacket cracking and short circuits.

With modern electronics becoming denser, Electromagnetic Interference (EMI) is a major concern. Unshielded cables act as antennas, picking up noise that can disrupt your sensitive PCB assembly.

Is the cable static (fixed behind a wall) or dynamic (attached to a moving print head)?

For dynamic applications, the "bend radius" is critical. You must ensure the cable assembly includes proper strain relief (overmolding or cable glands) at the connector end. This prevents the wire from snapping off the solder pads due to fatigue.

Beyond voltage and current, consider impedance matching. For high-speed data (USB, Ethernet), the impedance of the cable must match the PCB traces (typically 90 or 100 ohms) to prevent signal reflection.

A common friction point in hardware manufacturing is sourcing PCBs from one vendor and cables from another. This leads to "finger-pointing" when connectors don't fit.

Choosing a provider like NextPCB that handles both board fabrication and cable sourcing offers distinct advantages:

Pro Tip: When submitting your Gerber files for a quick turn PCB order, always upload the datasheets for any wire-to-board connectors. This allows our engineers to validate the footprint immediately.

Reliability is non-negotiable. Professional cable assembly manufacturing should adhere to the IPC/WHMA-A-620 standard (Requirements and Acceptance for Cable and Wire Harness Assemblies).

At NextPCB, our testing protocol includes:

This rigorous approach ensures that the cable assembly functions as safely as the circuit board it connects to.

Yes. We offer full turnkey PCB services. We can source standard cables or manufacture custom wire harnesses to your exact drawing specifications, ensuring perfect fitment with your PCBA.

Off-the-shelf cables have fixed lengths and pinouts. Custom assemblies allow you to specify exact lengths (saving space), specific pin mappings, and specialized jacket materials, often necessary for compact or industrial designs.

Use standard connectors (like generic equivalents to expensive brands) where possible, and avoid over-specifying the length. Consolidating your PCB manufacturing and cable orders with one supplier also reduces shipping and administrative costs.

Don't let poor cabling compromise your high-quality circuit boards. NextPCB provides industrial-grade PCB assembly and custom cable integration services trusted by engineers worldwide.

Whether you need a prototype in 24 hours or mass production support, we are your one-stop solution.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now