Arya Li, Project Manager at NextPCB.com

Support Team

Feedback:

support@nextpcb.comIn the complex world of PCB manufacturing and PCB assembly (PCBA), vias are the vital lifelines connecting different layers of a circuit board. However, if left exposed (uncovered), these small holes can become a source of significant failure during the soldering process.

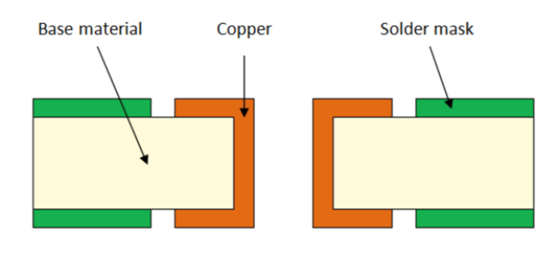

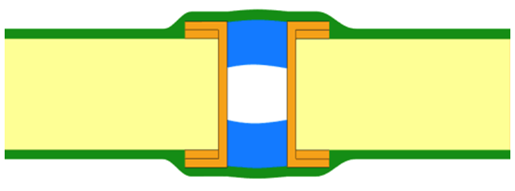

Figure 1: Solder paste may enter uncovered vias, leading to inadequate solder joints.

The most common issue with exposed vias is solder wicking. During reflow soldering, molten solder paste can be drawn down into the via hole through capillary action. This "theft" of solder leaves insufficient paste on the actual component pad, leading to weak solder joints, open circuits, or even tombstoning. Furthermore, exposed vias can cause accidental short circuits if they are too close to component pads.

As we move into 2026, with electronic designs becoming denser and component pitches shrinking (often below 0.5mm), choosing the right via protection method is a critical reliability decision. This guide breaks down the three primary techniques: Tenting, Plugging, and Filling (VIPPO).

The industry standard IPC-4761 (Design Guide for Protection of Printed Board Via Structures) categorizes via protection into seven types. Understanding these helps you specify exactly what you need in your Gerber files, avoiding delays in your turnkey PCB orders.

Via tenting is the most basic and low cost PCB solution. It involves bridging the solder mask material (LPI - Liquid Photoimageable) over the via hole, creating a "skin" over the opening.

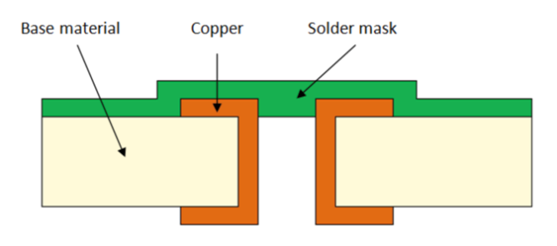

There are two common ways to implement via tenting:

Vias are closed on one side and remain open on the other side of the PCB.

Figure 2: Via closed on one side, open on the other.

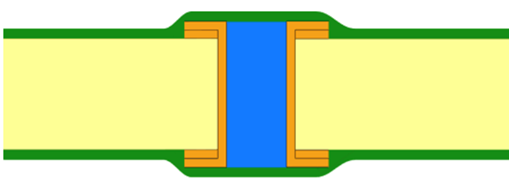

Vias are covered with solder mask on both sides of the PCB.

Figure 3: Via covered on both sides.

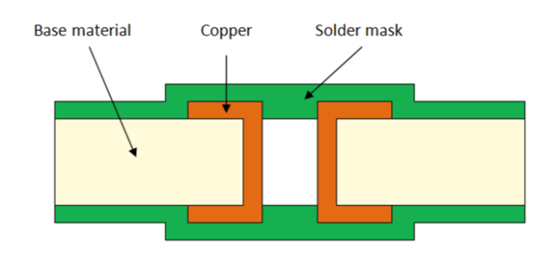

Via plugging means the via is partially filled with non-conductive media such as epoxy/resin or solder mask ink. This is more robust than tenting.

The via is partially filled and overprinted with conventional solder resist from one side, while the other remains open.

Figure 4: Partial filling with one side open.

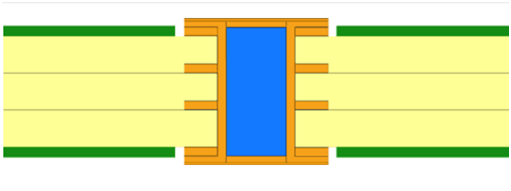

Filling the via with non-conductive media and overprinting it on both sides of the PCB.

Figure 5: Via plugged and overprinted on both sides.

Technical Note: The diameter of plugged vias should typically be smaller than 0.5mm. For multi-layer PCBs, one-sided plugging is often recommended because encapsulated gas in double-sided plugged vias can expand and cause cracks during high-temperature welding.

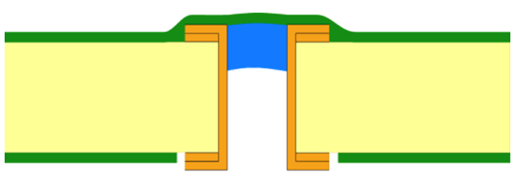

For high-reliability designs, especially for Via-in-Pad solutions, via filling is essential. This prevents solder paste from being sucked away from the pad into the via hole.

The via is filled completely with non-conductive paste and overprinted with normal solder mask/paste.

Figure 6: Full resin filling process.

This is the most advanced method. First, the via is plated and cleaned, then non-conductive paste is pressed in and hardened. Finally, the ends are planarized and plated over with copper to create a flat, solderable surface.

Figure 7: The VIPPO process - ideal for BGA pads.

This technology facilitates additional routing traces among BGA vias and is applicable to stacked micro-vias and blind vias.

| Feature | Via Tenting | Via Plugging (LPI) | Via Filling (Resin/VIPPO) |

|---|---|---|---|

| Cost Impact | Low (Standard) | Medium (+10-15%) | High (+30% or more) |

| Reliability | Standard | High | Ultra-High |

| Solder Wicking Risk | Moderate | Low | Zero |

| Best Application | General Consumer Electronics | ICT Test Points | HDI, BGA Designs, Aerospace |

The primary difference lies in thermal conductivity and the Coefficient of Thermal Expansion (CTE). Non-conductive via filling uses a special epoxy resin that closely matches the CTE of the PCB laminate (FR4), reducing the risk of barrel cracks during thermal cycling. In contrast, conductive via filling uses epoxy loaded with silver or copper particles to improve thermal dissipation. Despite the name, non-conductive fill is preferred for 95% of signal vias because the via barrel is already plated with copper for electrical conductivity, and resin provides better mechanical stability.

VIPPO is essential for High-Density Interconnect (HDI) boards because it allows vias to be placed directly on component pads without causing solder defects. In standard designs, a via near a pad must be connected by a short trace ("dog-bone"). With shrinking BGA pitches (0.5mm or less), there is no room for these traces. VIPPO fills the via and caps it with a flat copper surface, preventing solder from wicking down the hole and ensuring a reliable surface for SMD component mounting.

Via tenting can significantly impact assembly yield if the solder mask "tent" breaks or is inconsistent. If a via is improperly tented, solder paste can migrate from the SMT pad into the via during the reflow process, a phenomenon known as solder wicking. This often leads to "insufficient solder" or "dry joints" on critical components like BGAs and QFNs. For high-reliability PCBA, switching from tenting to via plugging or filling is recommended to guarantee zero solder loss.

Yes, via plugging or filling typically increases manufacturing costs by 15% to 60%, depending on the IPC type. Standard via tenting is usually included in the base price. Via plugging requires additional labor for ink application and curing. The most expensive method, IPC Type VII (VIPPO), involves specialized processes including secondary drilling, resin injection, vacuum sealing, precision planarization (sanding), and additional plating steps to create the copper cap.

No, it is generally not recommended to tent thermal vias located under a component's exposed thermal pad. Tented vias can trap air or gasses during the reflow process, leading to "voiding" in the thermal solder joint. Voids act as thermal insulators, significantly reducing the heat dissipation efficiency. Instead, thermal vias should either be left open (if small enough) or completely filled and capped (VIPPO) to provide a smooth, continuous thermal path.

Every via covering type has its advantages and disadvantages. At NextPCB, we support all IPC-4761 standards to ensure your PCB assembly prototype or mass production meets the highest quality requirements.

Ready to start your next project?

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now