Julia Wu - Senior Sales Engineer at NextPCB.com

Support Team

Feedback:

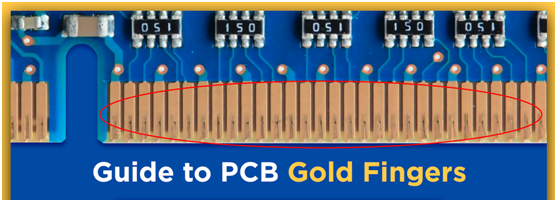

support@nextpcb.comIn the world of printed circuit board (PCB) interconnection, durability and signal integrity are paramount. Gold fingers are the gold-plated columns found along the connecting edges of printed circuit boards (PCBs). They serve as the critical connecting interface between a secondary PCB (like a graphics card or RAM stick) and the computer's motherboard.

For engineers and procurement specialists looking for reliable PCB manufacturing, understanding the specifications of gold fingers is essential to prevent connection failures and signal loss.

A common misconception in low cost PCB sourcing is treating all gold finishes the same. However, for gold fingers, the type of plating makes the difference between a board that lasts 10 cycles and one that lasts 1,000 cycles.

>> Recommend reading: HASL vs ENIG: An Ultimate Guide on Surface Finish

Gold fingers primarily use Electroplated Nickel Gold, commonly known as "Hard Gold."

While ENIG is a popular surface finish for the rest of the PCB assembly (soldering pads), it is generally too soft for edge connectors. Pure soft gold wears away quickly, exposing the underlying copper to oxidation. However, for cost-sensitive prototypes that will not be unplugged frequently, some designers may opt for ENIG, though NextPCB recommends hard gold for reliability.

Gold fingers act as the "nervous system" connectors between different circuit boards. As we move into 2026, with the rise of PCIe 6.0 and high-speed data transmission, the precision of these connectors is more critical than ever.

To ensure your turnkey PCB project goes smoothly, your design must adhere to strict manufacturing rules. At NextPCB, we verify these details during our DFM (Design for Manufacturing) check.

Producing gold fingers requires specific steps in the quick turn PCB fabrication process that differ from standard boards.

Since hard gold is electroplated, electric current must flow to the finger area. Manufacturers add a "plating bar" or "tie-bar" to the edge of the panel to connect all fingers. This bar is routed off (removed) after the plating process. Note: If your gold fingers are not on the edge of the board, electroplating becomes difficult or impossible without special lead lines.

To ensure the PCB fits easily into a female connector (like a PCIe slot) without damaging the contacts, the edge must be beveled.

Whether you are designing a complex server motherboard or a simple consumer electronic device, following these DFM tips will save you time and money on your PCBA orders:

Pro Tip: Looking for a low cost PCB solution? If your board requires gold fingers, avoid placing them on multiple sides of the board unless necessary, as this increases processing steps and cost.

Repairing gold fingers is difficult but possible using specific plating rework kits or gold conductive epoxy. However, the repaired finger will never be as durable as the original electroplated version. For production batches, replacement is usually required.

The cost is driven by two factors: the market price of gold and the extra processing steps (taping, electroplating, and beveling). However, using a turnkey PCB service like NextPCB can optimize panel utilization to keep costs down.

Immersion gold (ENIG) is a chemical reaction depositing a thin layer (1-3μin). Gold fingers use electrolysis to deposit a thick layer (30μin+). ENIG is for soldering; Gold Fingers are for mechanical connection.

Gold fingers are a small part of the PCB, but they determine the reliability of your entire system. Don't leave your connection quality to chance.

At NextPCB, we specialize in high-precision PCB manufacturing and PCB assembly. Our engineers review every gold finger design for IPC compliance before production begins.

Experience industrial-grade quality with quick turn delivery.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now