Support Team

Feedback:

support@nextpcb.comMicrosection is one of the most common and important analysis methods in the PCB industry. It can accurately test if the quality is good or not, furthermore, it can also analyze the cause of the problems, provide the evidence for solutions, and evaluate the process of improvement.

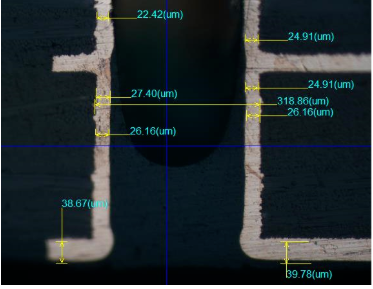

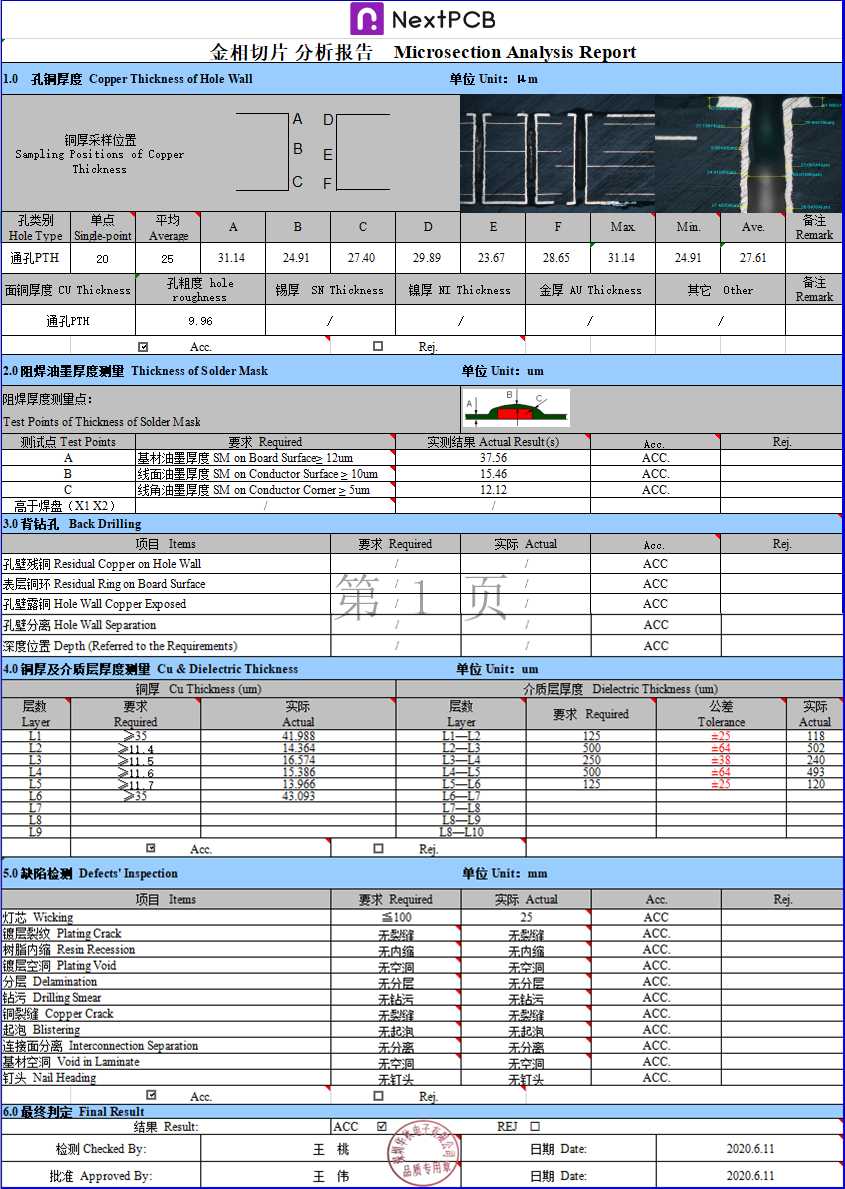

The cross-section is mainly used to check the copper thickness, the number of layers, laminated structure, through-hole size, hole copper thickness, hole wall roughness, etc.

Vertical Micro section: Vertical Micro section: Cut in the perpendicular direction to the PCB surface and observe the condition of the profile. It's usually used to observe the quality of the plated hole, the laminated structure, and the internal interface. Vertical Micro section is commonly used in Microsection.

Horizontal microsection: Grind down the stacking direction of the printed circuit board along with the layers, which is used to observe the condition of every layer. It's usually used to assist the vertical microsection to analyze and judge the quality.

Microsection includes a series of methods and steps such as sampling, mounting, slicing, polishing, corrosion, and observation to obtain a smooth cross-sectional structure of the PCB. Then analyze the details of the slice through Metalloscope, because you can make the correct analysis and offer the right solutions only through making the correct judgment of slices.

Therefore, the quality of the slice is very important, and the slice with poor quality will lead to a misjudgment in the analysis. As the most important equipment of analysis, the magnification of the Metalloscope is from 50 to 1000 times and the measurement accuracy deviation is within 1 μm.

(The hole copper≥20μm, the surface copper≥35μm, hole side roughness≤25um. The hole side straightness, the inner/outer layer, and the hole copper are fully connected)

Nowadays, the price competition in the PCB market is fierce, and the cost of PCB board materials is also on a rising trend. In order to enhance competitiveness, more and more PCB manufacturers are monopolizing the market with low prices. However, the truth behind these low prices is to reduce material costs, simplify the manufacturing process, and delete the process of quality control, so the products are prone to various problems.

When the PCB is magnified 500 times, can your PCB quality stand the test?

Since the establishment of NextPCB, we have always put quality first. NextPCB strictly selects the A-grade PCB of Shengyi/Kingboard. The material is sliced to confirm the quality of the material, and eliminate the wrinkles of raw material, pinholes, pits, and other defects.

After the lamination of the multi-layer, we will check the interlayer binding force to make sure the media thickness of every layer to be done by the requirement of our customers.

Every detail of NextPCB boards can withstand inspection, this is the real quality guarantee. For the first time, NextPCB provides free microsection reports for 6+ layers, which is a promise to customers for the reliability of high multilayer boards!

NextPCB promises PCB quality with higher quality control so that you could complete your project successfully.

Now NextPCB gives away a free microsection report for order ≥$300. Seize the chance to achieve a better project!

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now