PCB is the heart of electronic products, and its quality and reliability are directly related to the quality and reliability of electronic products. Therefore, high-reliability PCBs have become the basic requirements of many electronic products. So the question is, how to judge a high-reliability PCB?

PCB Board Material

As the core raw material of PCB, copper-clad laminate accounts for 30% of PCB production cost. It can be said that if the copper-clad laminate is selected, the PCB is half the success. At present, copper-clad laminates are mainly divided into three levels: A, B, and C. Grade A meets the requirements of military industry-grade and is the best grade sheet; Grade B is used for low-grade civilian use without quality assurance; Grade C is a lower grade, purely for cost and no quality assurance.

How to recognize that it is a grade A sheet material and ensure that your circuit manufacturer does not use low-grade sheet material?

- Method 1: Generally, all panel manufacturers will mark the A grade materials, like the A grade materials in the KB material, and the words KB in the plate, if it is other grades like the B and C grades in the KB If the performance is poor, there is no mark, so the easiest way to distinguish is to see if there is a mark in the plate;

- Method 2: In addition to the mark, the contract should also indicate that it is a grade A material, otherwise all the responsibilities caused by the plate will be borne by the board factory.

Copper Thickness of the Board

Through-hole plating is a very important part of the PCB manufacturing process. To provide electrical connections for different levels of conductive metals, it is necessary to plate the walls of the through-holes with metal copper with good conductivity. The increasingly fierce competition of terminal products will inevitably put forward higher requirements for the reliability of PCB products, and the thickness of the through-hole plating layer has become one of the items to measure the reliability of the PCB. An important reason that affects the thickness of PCB hole copper is the deep plating ability of PCB electroplating.

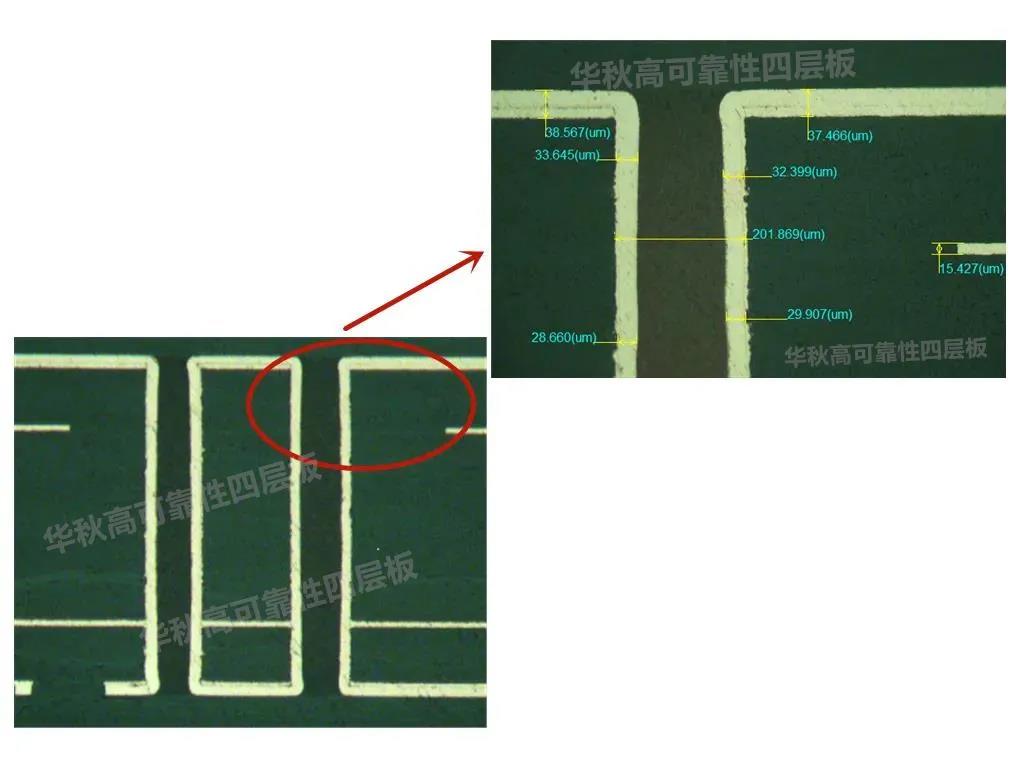

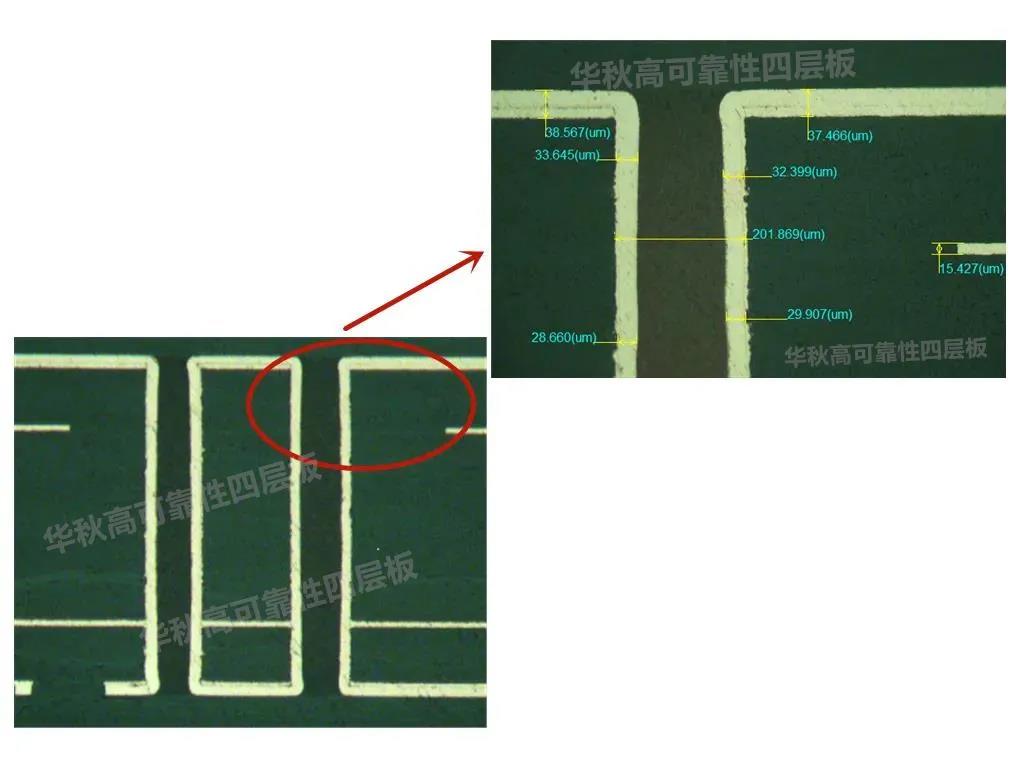

An important indicator for evaluating the effect of PCB plated through holes is the uniformity of the copper plating thickness in the hole. In the PCB industry, the deep plating capacity is defined as the ratio of the thickness of the copper plating at the center of the hole to the thickness of the copper plating at the hole.

According to the IPC Grade II standard, the hole copper needs to be ≥18μm .

The hazards of insufficient copper thickness:

- 1. If the connected line has impedance requirements, it will affect the line impedance;

- 2. It can lead to a slight open circuit, which can be energized immediately, but not from time to time;

- 3. The hole copper is too thin, and the appearance is difficult to find, which makes it difficult to analyze the cause of the abnormality of the product.

The above are the two basic methods for judging high-reliability PCBs.

No, it doesn't matter, there is an easier way, that is to come to Huaqiu Circuit (NEXTPCB) for proofing and experience the high-reliability and short-delivery boarding experience.

High reliability, made in Huaqiu( NEXTPCB )

For a long time, Huaqiu(NEXTPCB) insists on "making high-reliability PCBs, increasing efficiency and reducing costs for the electronics industry" as its mission, and it has been recognized and trusted by more and more customers. High reliability is Huaqiu's commitment, and it is also Huaqiu's unswerving persistence.

It is difficult to make a PCB, and it is even more difficult to make a reliable PCB. In order to improve the high reliability of PCB, Huaqiu(NEXTPCB) strictly selects Shengyi/Kingboard A-grade board. Although the cost is more than tens of yuan per square meter, it is the basic guarantee for Huaqiu's high-reliability PCB.

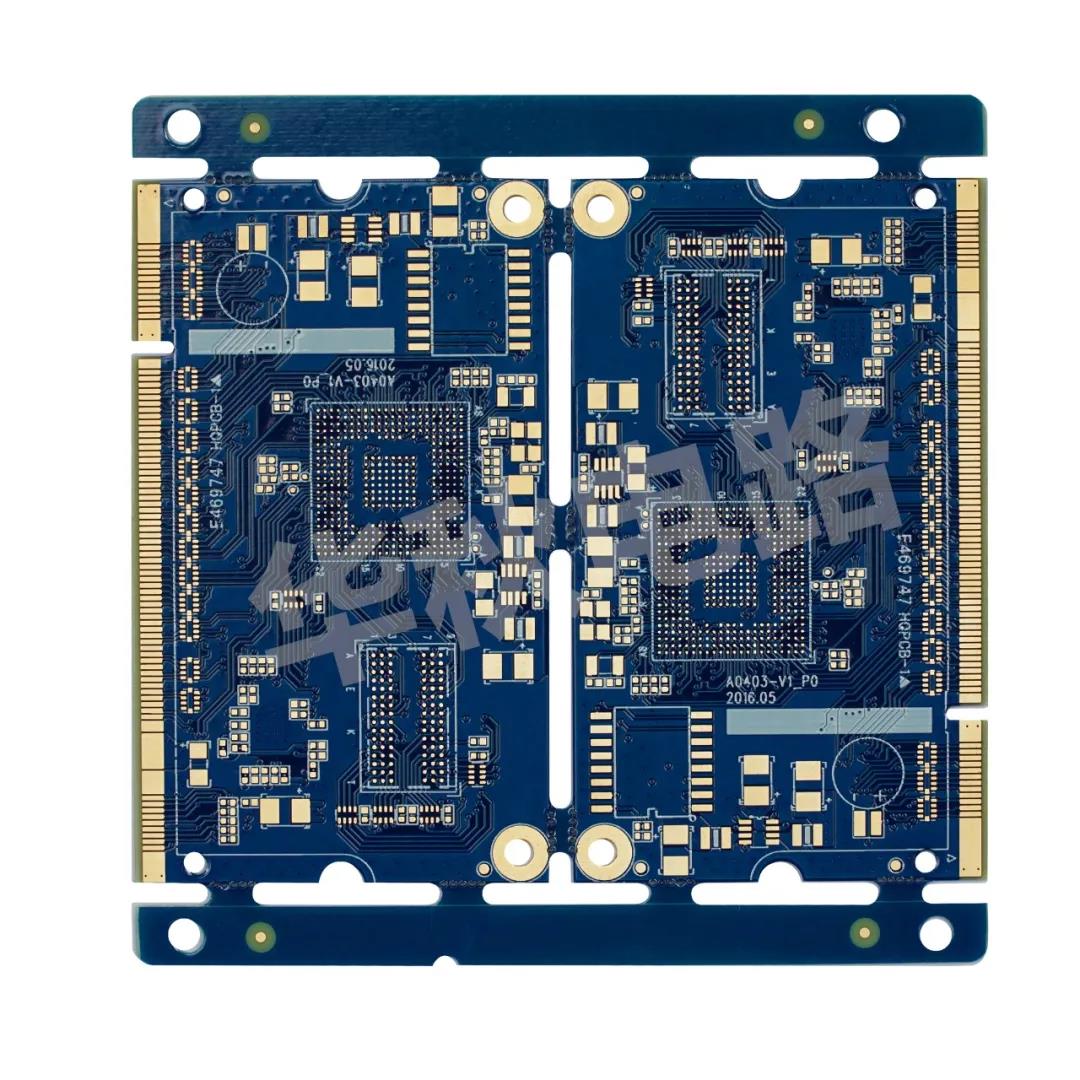

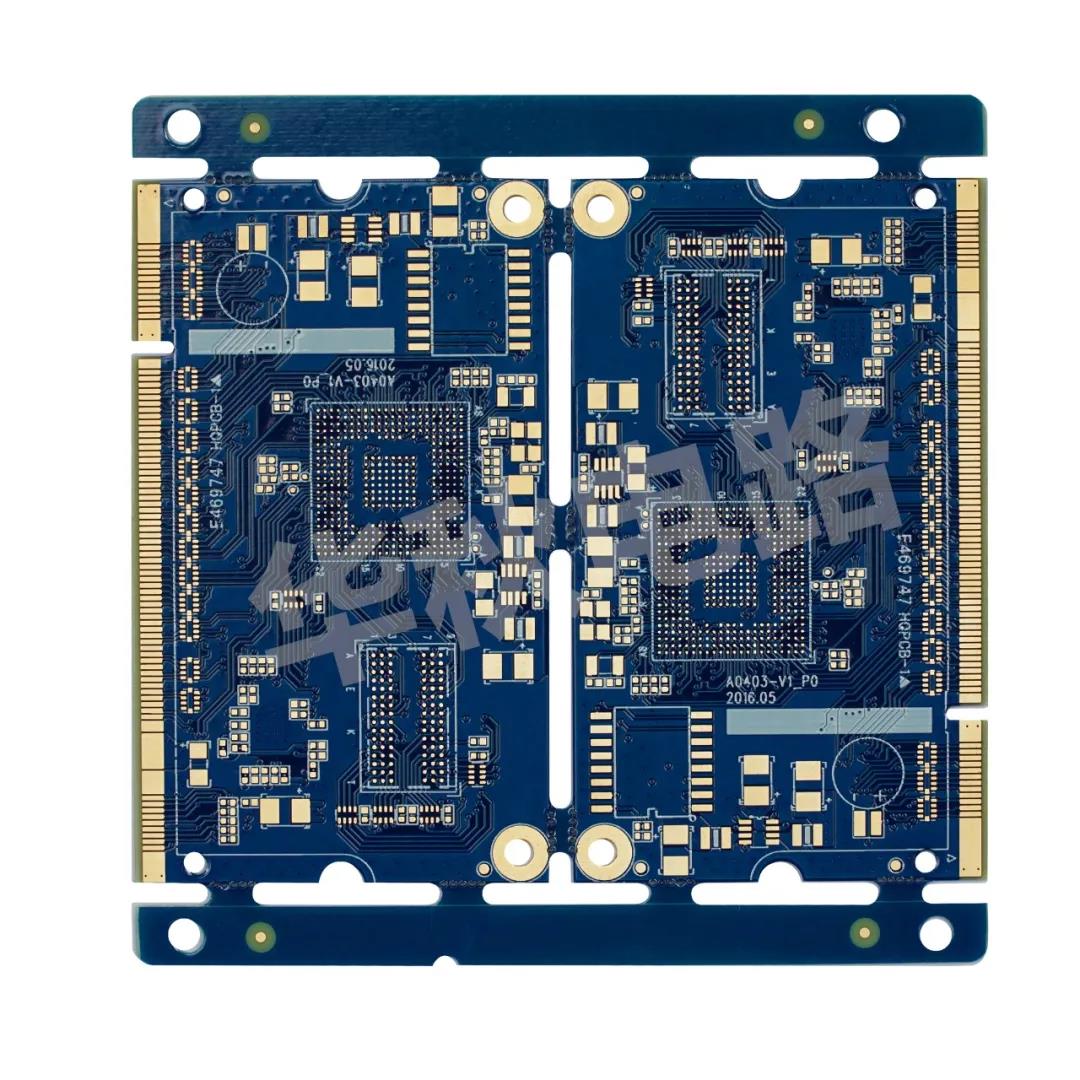

Copper thickness is the core indicator for judging PCB reliability. Within a reasonable range, the thicker the copper thickness, the better the reliability and conductivity of the PCB. Huaqiu(NEXTPCB) strictly inspects its products in accordance with IPC Grade II standards. The following four-layer board slice analysis diagram shows that the copper thickness of Huaqiu's high-reliability four-layer board is greater than 20μm.

Strict quality control has allowed Huaqiu(NEXTPCB) to be recognized by well-known companies such as Huawei, Tencent, Midea, ZTE, Haier, and China South Locomotive. It has maintained a relatively good and lasting cooperative relationship in terms of business breadth and depth.

To "become the most trusted one-stop service platform for the electronics industry supply chain in the world", for this goal, Huaqiu(NEXTPCB) will continue to work hard, continue to consolidate the foundation, cultivate internal skills, improve process capabilities, improve production management levels, and increase efficiency and reduce the efficiency of the electronics industry.

PCB Assembly

PCB Assembly

Layer Buildup

Layer Buildup

Online Tools

Online Tools

PCB Design-Aid & Layout

PCB Design-Aid & Layout

Mechanics

Mechanics

SMD-Stencils

SMD-Stencils

Quality

Quality

Drills & Throughplating

Drills & Throughplating

Factory & Certificate

Factory & Certificate

PCB Assembly Factory Show

Certificate

PCB Assembly Factory Show

Certificate