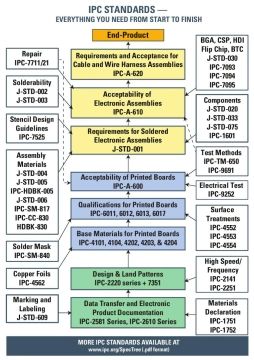

What are IPC 6012 Standards?

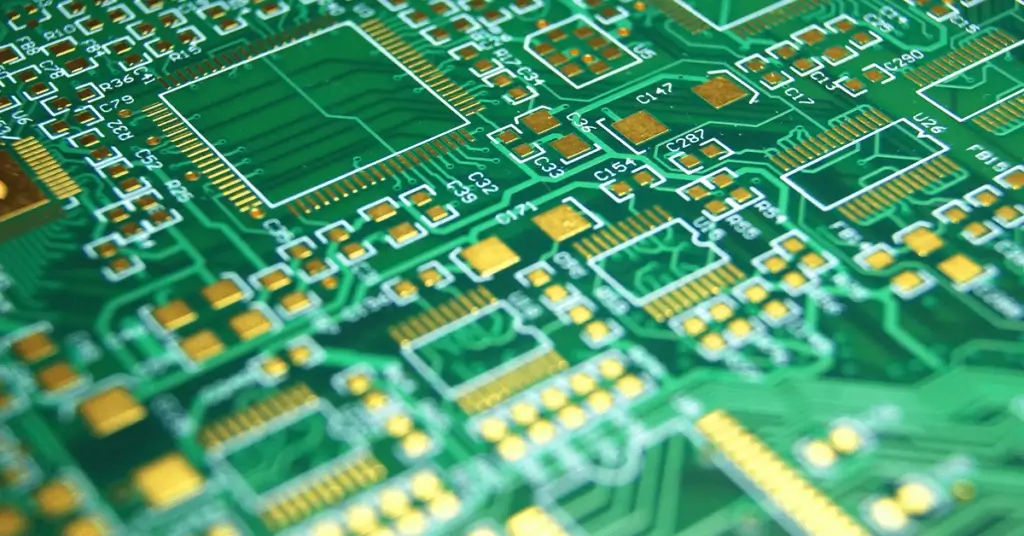

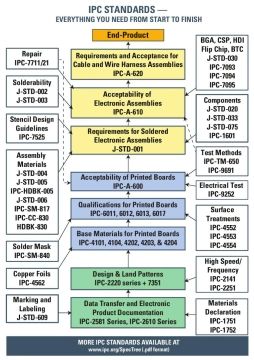

At present, the electronics industry is a fast-developing industry, with the current needs of human beings. Because of that many pieces of equipment are upcoming with time, where the PCBs play an important role play. Considering the signal transmission and interconnection of the electronic components Rigid Printed Boards play an important role. Therefore, increasing and maintaining the quality and reliability of these PCBs is an important task in this field. To ensure these factors the electronic experts in this domain developed the IPC standards. IPC 6012 basically explains the performance specification introduced by the IPC (Association Connecting Electronics Industries). Here, there are descriptions of the fabrication and performance of the PCBs. Mainly these standards are possible to divide into three classes. They are as follows:

- Class 1 - General Electronic Products

- Class 2 - Specialized service electronic products

- Class 3 - High-performance electronic devices

Therefore, the related field experts are always trying to maintain the quality of the work by following the standards mentioned in IPC 6012. With that industries will be able to achieve the durability, reliability, and high quality of the PCB product. The most important factor here is, service providers and electronic industries can meet the demanding of the clients. Following these standards will give positive feedback to the clients since the service providers have to do quality work.

Standard Version Evolution: IPC-6012

IPC-6012's framework originated with its predecessor, IPC-RB-276 (1992), which established the first dedicated performance standards for rigid PCBs. Its evolution continues through key milestones:

- 1996: Introduction of IPC-6012 as the official Qualification & Performance Specification, replacing IPC-RB-276.

- 1999-2010: Revisions A, B, and C (including amendments) progressively refined PCB classifications and material requirements.

- 2023 (Revision F): The current standard, incorporating significant technical expansions and enhancements.

Key Updates in IPC-6012 Revision F (2023)

Revision F introduces critical technical refinements:

- Standardized Back-Drill Depth Measurement (Section 1.4.3): Clarifies procedures by mandating depth measurement exclusive of surface copper plating, ensuring consistency.

- Defined PCB Cavity Types & Requirements: Establishes protocols for three cavity configurations with strict tolerances to boost reliability:

-- Type 1: Unplated cavities

-- Type 2: Cavities plated only on the floor or sidewalls

-- Type 3: Fully plated cavities

-- Uniform Requirements: ±0.005" depth tolerance and defined conductor/via spacing rules.

Classification of PCBs according to IPC 6012

Identifying the correct class according to the standards is an important factor. IPC 6012 basically lies on 3 main classes. As mentioned above, the standards come in 3 classes.

Furthermore, even though these all products are PCBs, there are different requirements that should be achieved by the PCB designers to get the quality of the product.

Class 1

Class 1 is for electronic devices where their functionality of them is not critical. Mainly these products include low-power using and low-signal transmission electronics. Most of the cases the reliability of these products is not a case that takes into account.

Class 2

Class 2 is for the electronic products that develop for special case scenarios. Under this class performance and the reliability of the electronic product are highly taken into account. These electronic products are with moderate power consumption and moderate signal passing. Mainly these electronic products are for continuous working systems.

Class 3

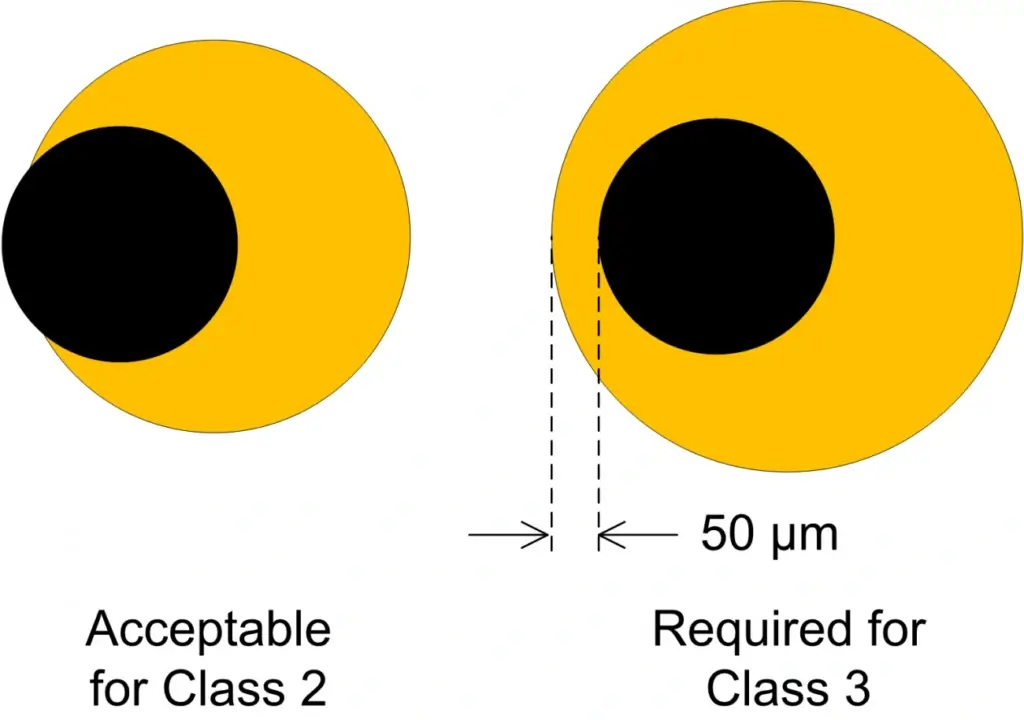

IPC-6012 Class 3 defines the strictest level of performance and reliability requirements for rigid PCBs. Boards meeting this class are essential for high-performance electronics where failure can have severe consequences—such as life-support systems, aerospace technology, critical military hardware, and high-speed/high-power computing applications.

Reliability is paramount in Class 3 PCB design and manufacturing. Following IPC-6012 standards, particularly Class 3 specifications, is crucial for PCB designers targeting mission-critical or high-performance electronics. Adherence ensures designs meet the necessary structural integrity, electrical performance, and long-term reliability demands inherent in the most challenging applications like aerospace, medical devices, and advanced datacenters.

Materials for the Fabrication according to IPC 6012

Selecting the appropriate materials for the fabrication of the PCBS helps to develop highly functioning and more reliable PCB products. IPC 6012 helps the manufacturers. This includes copper foil, laminate, and prepreg materials. Therefore, materials selection plays a critical role in the manufacturing of PCBs. Class wise following the fabrication materials helps to develop the demands of the clients.

Copper foils of the PCBs are for the creation of pathways for the pass signals through the PCB. These come with different thicknesses and different surface finishes. Considering the surface finishing of the PCBs is a very important fact because it has the capability to affect the electrical characteristics of the PCBs.

Laminate materials of a PCB are for the supporting to the structural strength of the PCB. Laminate materials are mainly made of woven glass cloth impregnated with epoxy resin. Mainly the thickness of the PCB depends on the functionality and the application. Moreover, the type of resin helps for the increasing of the electrical strength of the PCB.

In order to bond the layers of the PCBs, Prepeg materials are highly applicable in the industry. Therefore, the thickness of the PCB affects its electrical properties and reliability of the PCB. Using the correct guidelines to select the Prepeg materials helps the manufacturer to increase the reliability of the PCB.

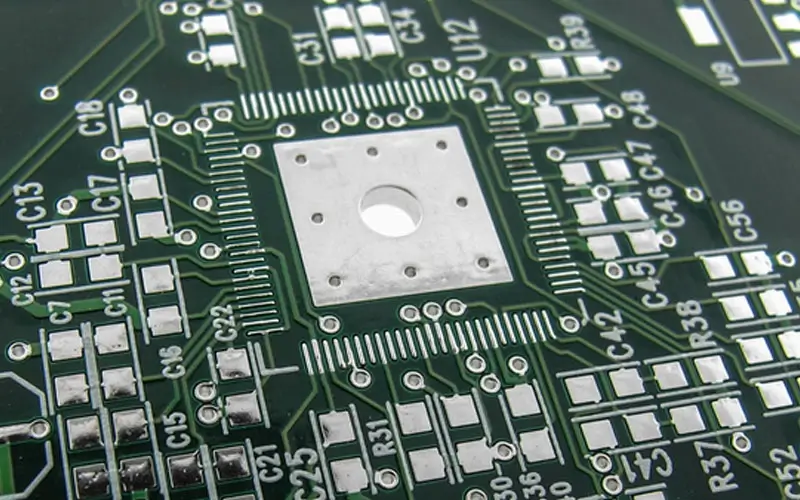

Design and Layout according to IPC 6012

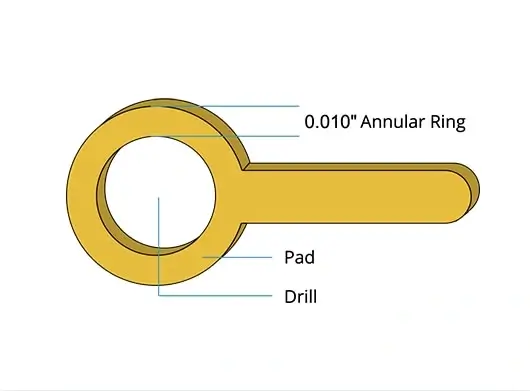

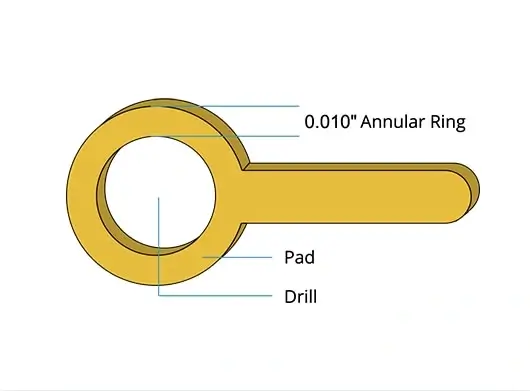

Considering the performance of the PCBs, the layout of the PCB plays a major role since the whole functionality of the PCB lies in the layout of the PCB. IPC 6012 clearly describes the layout of PCBs, minimum annular ring size and the conductor sizes, minimum spacing between the conductors, and the recommended edge clearance. By following these guidelines, the manufacturer can achieve the highest quality and the expected functioning of the PCB. And this will minimize the risk of failure because these guidelines are mainly coming with the proper guidance of the expertise in the field.

IPC 6012 clearly explains these factors in relation to all 3 classes. If we take an example Class 1 printed boards may have smaller conductor widths and spacing, while Class 3 printed boards require larger conductor widths and spacing. The main reason behind this is, these get optimized to meet the higher performance requirements.

IPC 6012 especially describes the minimum conductor width and spacing requirements that are suitable for the requirements and class. As an example, it is possible to understand that Class 1 boards consist of smaller conductor sizes and spacing compared to the class 3 specifications.

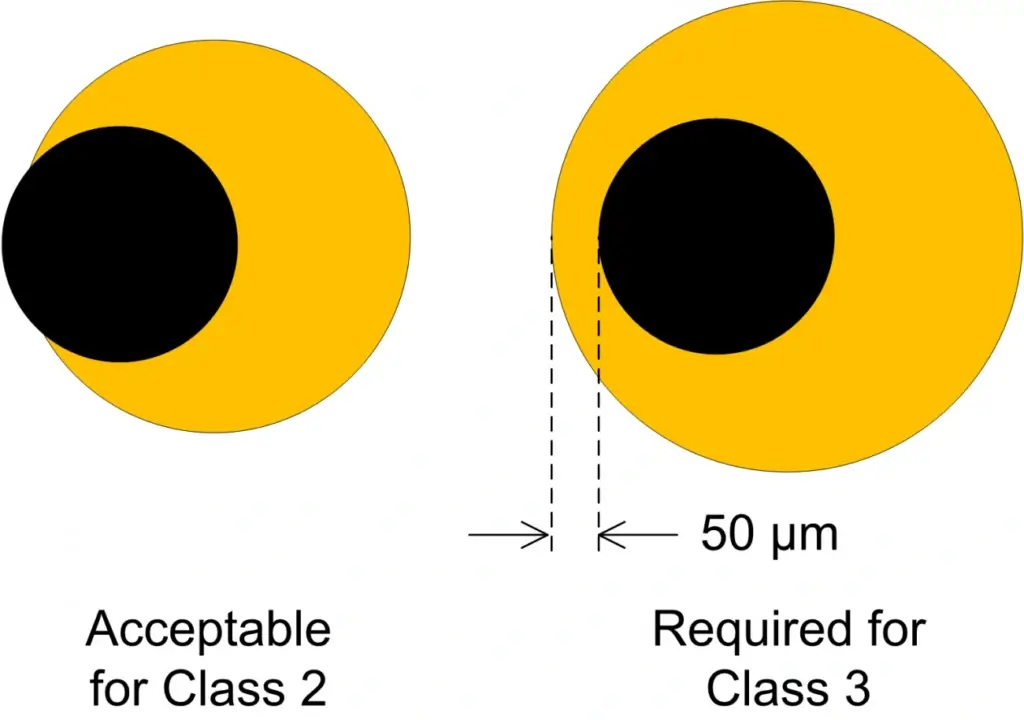

The annular ring size is directly connected with the diameter of the drilled hole and the thickness of the copper plating. Following the IPC 6012 standards helps to get support from the annular ring for the conductive trace. Considering the above image it can understand that following the proper IPC 6012 guidelines help the manufacturer to reduce the risks and defects.

Plating and Surface Finishes of PCBs

Plating and surface finishing are important tasks that PCB manufacturers should focus on to achieve the best products. IPC 6012 clearly explains the guidelines for the plating and surface cleaning of a PCB. These guidelines mainly depend upon the thickness of the board. The main two surface finishings are Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservatives (OSP).

Surface finishing helps to increase the solderability, overall electrical characteristics and protection of the PCB. And it makes a side effect on the mechanical properties of the PCB. Considering the other long-term issues, oxidation effects will be minimized by the proper surface finishing. Since these two actions, surface finishing and plating depend on the thickness of the PCB, the thickness of the PCB will depend upon the class of the PCB.

ENIG is a popular surface finish that provides a thin layer of gold over a layer of nickel. This is possible to apply to applications where high reliability and signal integrity is necessary.

OSP is a method that follows the application of an organic layer on the copper traces of the PCB. This is commonly applicable to cases where fine pitch and good solderability are essential.

Ensuring the high quality of the PCBs following the IPC 6012 standards is essential. Therefore, the manufacturers have to work very well according to the guidelines of these standards.

Testing and Inspection

Testing and inspection are the most important component that comes under the IPC6012 standards. The main reason behind that is testing and inspection of the product will help the manufacturer to determine whether they have reached the demands (specifications for materials, construction, dimensions, hole sizes, surface finish, and electrical properties) of the client by going through the correct approach. Therefore, these standards specifically describe different testing and inspection procedures that are possible to follow by the designer.

IPC 6012 include dimensional measurements, copper adhesion, solderability, and reliability testing. As an example, the Copper Adhesion test will illustrate the copper traces of the PCB, and whether they have connected clearly, Solderability test illustrates whether the PCB is possible to solder properly to other mounting components. Reliability tests illustrate whether the PCB has the proper functioning to work for the expected time period.

Other available tests are thermal cycling, humidity testing, and vibration testing. Therefore, it can be understood that following of these IPC 6012 explained testing will help the designer to ensure the products' quality.

Quality Control

Quality control is an important task that comes under the IPC 6012 standards. The main reason behind that is designers can understand the quality of the final product they made. Under this part, the designers have to ensure that they were able to achieve the correct standards that come for the correct PCB class. passing through the standards of quality testing simply implies that the work is successful.

In the quality control process, these factors are highly considered to ensure the quality of the product, materials, construction, dimensions, hole sizes, surface finish, and electrical properties. The main advantage of this is, designers can reduce the number of errors in the PCB, and future defects, and improve the results, performance and reliability of the PCB.

These standards for quality control clearly explain the conditions where the PCB should be rejected and conditions where the PCB should be accepted. By implementing effective quality control processes in accordance with IPC 6012, electronics manufacturers can ensure that their printed boards meet the required standards.

IPC-6012 vs. IPC-A-600: Clarifying the Roles

- IPC-6012 sets the benchmark: It defines the essential performance and manufacturing requirements for rigid PCBs, encompassing materials, structural integrity, and electrical/mechanical properties.

- IPC-A-600 governs inspection: It provides the visual acceptance criteria, establishing how compliance with IPC-6012 standards should be visually evident on the finished board – making it the critical standard for inspection and quality validation.

Advantageous of the IPC 6012

Following the IPC 6012 standards while manufacturing PCBs will give many advantages to both clients and manufacturers.

- Quality – Since the IPC 6012 clearly explains the quality of the PCBs, all the time throughout the developing process the quality of the PCB will increase continuously.

- Reliability – Since the process will undergo testing and inspection processes, the reliability of the PCB will optimize throughout the process. This will reduce the risk of failure of the electronic components.

- Better performance - IPC 6012 provides guidance on the design and layout of printed boards. This includes a minimum conductor and annular ring sizes, minimum spacing between conductors, and recommended edge clearance. By following these standards, electronics manufacturers can improve the performance of their products.

- Standardization of the industry – most of the industries in the domain of electronic manufacturing follow the IPC 6012 standards to ensure quality. So following the standards for the products allows the designer to ensure their quality in comparison to the others.

- Certification – IPC 6012 provides certification for the following standards. So as industrial people, the manufacturers can show these certificates to make sure that clients get satisfy with their skills and procedures.

Conclusion

IPC-6012 establishes critical standards and guidelines governing the fabrication, performance, testing, and quality control of printed circuit boards (PCBs). Adhering to IPC-6012 enables manufacturers to significantly enhance product quality, reliability, and performance. Crucially, the standard provides distinct requirements—including testing, quality control, and design procedures—tailored to three classes of PCBs (Class 1, 2, and 3). This structured approach directly reduces potential defects, improves production outcomes, boosts customer satisfaction, and enhances product safety. Implementing IPC-6012 delivers clear benefits for both manufacturers and end clients.

IPC-6012 Application at NextPCB:

At NextPCB, we actively uphold the highest IPC-6012 standards to ensure exceptional quality:

- Commitment to the Latest Standards: We strictly follow IPC-6012 Revision F requirements (e.g., back-drill specifications, cavity tolerances, copper wrap plating) to guarantee our rigid PCBs meet cutting-edge performance and reliability demands.

- Rigorous Process Integration: IPC-6012 is rigorously integrated throughout our design, fabrication, and validation processes. Supplemented by IPC-A-600 for acceptance inspection, we ensure both structural integrity and visual compliance at every stage.

- Proactive Design Support: We encourage leveraging our free online DFM tools and Gerber Viewer. These tools align with IPC-6012, enabling users to instantly verify design quality and manufacturability upfront, preventing costly issues.