Support Team

Feedback:

support@nextpcb.comDo you know that almost all the gadgets or electronic devices you use in your daily life have a common basic component? Almost any electronic device, including your PC, laptop, smartphone, game machine, microwave oven, TV, dishwasher, etc., can't work normally without PCB assembly. So, what is PCB assembly?

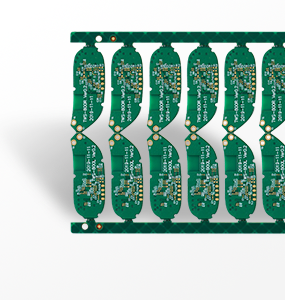

Like the page "PCB Assembly - The Basic Design Rules You Must Know" shows, What does PCB assembly mean? PCB assembly refers to the process of soldering and assembling electronic components on the preform and manufacturing printed circuit board (PCB). Usually using professional production machinery, mass production, t PCB assembly process is usually called PCBA.

PCB refers to the empty circuit board. In this state, the circuit board does not contain any electronic components and looks like a green slate with dividing lines and spaces. Therefore, the PCB itself cannot be used for work unless and until the whole assembly is completed.

PCBA, on the other hand, is also known as the process of soldering and assembling electronic components on circuit boards and finished/assembled circuit boards. The finished PCBA is actually used for electronic devices rather than PCBs.

The board assembly participates in various steps. This is a nonlinear process, which indicates that factors need to be considered, and the process can be changed and adjusted according to these factors. The expected results and the use of PCBA are one of the main factors that determine the assembly process of components and general circuit boards. The following are some PCB components of parts and components that need to be carried out:

When all the necessary components are ready, the assembly process can begin. But before we go into the assembly process (it's a different type), let's learn more about the circuit board itself.

Circuit boards are usually made of epoxy resin or other composite materials. It is used to physically support components and electrically connect them to form real-time circuits.

In the simplest sense, a PCB will consist of a thin layer of insulating material and a layer of copper foil, which are laminated onto the underlying substrate (usually made of epoxy resin, glass fiber or similar composites). The number of layers on a PCB depends on the purpose and application. Lines or circuit tracks on a PCB are created with the help of chemical etching. These circuits facilitate the flow of current and connect various components together.

There are different types of circuit boards or PCBs. According to the application type, the manufacturer will select PCB. Here are some of the most widely used PCB types:

About the detailed information of types of PCB, please see the above article -- What is PCB and Types of PCB

The technology used to assemble the circuit board and its various components is called the installation technology board components in the circuit. Depending on the application, cost, size, and other considerations, manufacturers use different kinds of installation methods. Here are some of the most commonly used techniques:

Surface mount technology (SMT) is a method to connect the electronic components standing on the PCB directly to the surface of the circuit board. The final circuit board is called a surface-mount device (SMD). The technology was originally known as "flat-mount.".

At present, most of the electronic boards are made by SMT. Due to its increased circuit density and ability to produce results on smaller boards, it has replaced the more traditional via technology (more on the next point). Generally, SMTS uses solder to connect components to the circuit board, but in some cases, adhesive points can also be used on the second side to keep the components in the reflow oven.

Surface mount technology (SMT) is a method to connect the electronic components standing on the PCB directly to the surface of the circuit board. The final circuit board is called a surface-mount device (SMD). The technology was originally known as "flat-mount.".

At present, most of the electronic boards are made by SMT. Due to its increased circuit density and ability to produce results on smaller boards, it has replaced the more traditional via technology (more on the next point). Generally, SMTS uses solder to connect components to the circuit board, but in some cases, adhesive points can also be used on the second side to keep the components in the reflow oven.

Electro-mechanical components use electrical and mechanical units to cover a wide range of functions, such as power generation, control switches and other mechanical tasks. Since electromechanical components are often used in applications with complex wiring and components, the components need to be put together manually.

Therefore, it can usually be time-consuming. However, major manufacturers like raypcb like us, use this technology and break the process down into segments, and use experts from each segment. So we can shorten the lead time.

Surface mount technology is most commonly used in personal computers and is still in use. It is one of the most widely used technologies in the field of electronics, widely used in consumer electronic products, including smartphones, computers, TVs, microwave ovens, and so on. But before SMT, it was a via technology that dominated the PC market.

In fact, IBM pioneered this process and pushed it into the mainstream. At present, through-hole technology is more used in larger components, such as electrolytic capacitors and semiconductors, because it can better maintain the components than SMT.

Due to its versatility in power enhancement and mechanical functions, electro-mechanical components are commonly used in AC and DC power distribution, computer interface, and control systems.

PCB is a very close and dear part of our contemporary life, although we still don't notice it. For decades, the technology of effective assembly and installation of components has rapidly developed into a fast-to-point structure from via to SMT. In addition, each of them has its own advantages and disadvantages, making them very suitable for some tasks rather than others.

| PCB type | abstract |

| For a simple system, low cost, common for amateurs | |

| Double-layer PCB | Not as common as multilayer boards. Use both sides of a board |

| Multilayer PCB | Usually mass production, economical, compact, up to 10 or 12 layers |

| Rigid PCB | More robust substrate, high impact applications, military, aerospace |

| Flexible PCB | Application of mobile parts, higher cost, and longer service life |

| Metalcore PCB | Sheet metal, copper, specialist applications, such as conductive or thermal |

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now