Support Team

Feedback:

support@nextpcb.comThe duty of the substratum for a print circuit board is as crucial as the duty of a motherboard for digital tools. According to the home of PCB substratum, it can be split right into natural substratum as well as not natural substratum.

The natural substratum is made up of several paper layers fertilized with phenolic material or non-woven or glass fabric layers fertilized with epoxy material, polyimide, cyanate ester, BT material, and so on.

Not natural substratum mostly consist of ceramic and also metal products, such as light weight aluminum, soft iron, as well as copper. The function of this substratum generally depends upon warmth dissipation demands.

The inflexible motherboard substratum we typically utilize is natural substrates, such as FR-4 epoxy glass fiber towel substratum, which utilizes epoxy material as the glue, and also digital quality glass fiber towel as the enhancing product.

We see that FR-4 makes use of epoxy material as a binder. The resin product has a crucial particular criterion: the glass change temperature level Tg, which describes the temperature level shift factor at which a product modifications from a reasonably stiff or "glass" state to a versatile or soft state.

The temperature level at which a glazed compound reversibly changes in between the glazed state as well as the high flexible state. That is to claim if the temperature level of the glue epoxy material of the FR-4 substratum is less than Tg, the product remains in a stiff "glass state" currently. When the temperature level is greater than Tg, the product will certainly be soft as well as adaptable like rubber.

The state of the resin product at a temperature level listed below Tg is a tough strong, that is, a glass state. Under the activity of exterior pressure, there is a specific contortion yet the contortion is relatively easy to fix, that is, after the outside pressure goes away, the contortion likewise vanishes, which is the state of a lot of materials.

When the home heating temperature level of the material goes beyond Tg, the molecular chains in the amorphous state start to relocate, as well as the material goes into an extremely flexible state. The material in this state resembles the elastomer in the rubber state, yet it still has relatively easy to fix contortion residential or commercial properties.

It deserves keeping in mind that after the temperature level goes beyond the Tg worth, the product becomes soft progressively, and also as long as the material does not decay, when the temperature level is cooled down listed below the Tg worth, it can still go back to the exact same inflexible state as in the past.

Nitrogen has a Td worth called thermal disintegration temperature level. When material products are heated up to specific heat, the material system starts to disintegrate. When the chemical bonds in the material start to damage and also unpredictable elements overflow, the material in the PCB substratum ends up being much less. The Td factor describes the temperature level factor at which this procedure starts. Td is typically specified as the disintegration temperature level when 5% of the initial mass is shed. However this 5% is extremely high for multilayer PCBs.

We understand that the variables that influence the particular insusceptibility of the transmission line on the PCB consist of the line size, the range in between the trace and also the referral airplane, the dielectric constant of the sheet, and more. The quantity of material in the substratum product has a wonderful impact on the dielectric residential or commercial properties, as well as the volatilization of the material additionally has an impact on regulating the range in between the trace as well as the recommendation aircraft.

This Td worth requires to be thought about for the lead-free soldering procedure.

Researches have revealed that the Td worth of standard FR4 plates is above 300 ℃, while the Td worth of leaded soldering totally fulfills the temperature level of 240 ~ 270 ℃, so why exists a lead-free variation?

The 5% material mass volatilization price is as well huge for multi-layer PCBs that call for insusceptibility control. For tin-lead soldering procedures, products at a temperature level of 210 to 245 ° C will generally not undertake substantial thermal disintegration. Yet normal Tg FR-4 substratum has actually started to shed 1.5 ~ 3% of the material top quality if the temperature level got to the variety of 240 ~ 270 ℃ for lead-free soldering. This degree of disintegration might likewise impact the lasting dependability of the substratum product or create delamination or space flaws throughout the welding procedure, particularly when it comes to several welding procedures or revamp home heating. For that reason, if a lead-free soldering procedure is made use of, along with the Tg worth, the Td worth need to additionally be taken into consideration.

The efficiency of the substratum product differs significantly in between the Tg worth over as well as listed below the Tg worth. Nevertheless, the Tg worth is normally referred to as a very accurate temperature level worth. It does not indicate that the substratum comes to be extremely soft when the temperature level surpasses this worth.

The Tg worth of the material system has 2 primary impacts on the efficiency of the product:

As the board broadens as a result of warmth, you can think of that the spacing of the BGA pads modifications throughout SMT soldering. Furthermore, the mechanical anxiety brought on by thermal growth will certainly create great fractures on the PCB traces and also pad links. These fractures might not be located throughout the last open/short circuit examination after the PCB manufacturing is finished. While the mistakes might show up after SMT as well as various other additional home heating, as well as the most awful situation was that no apparent mistakes showed up when SMT was warmed. After the item was sent, in the alternative usage setting of cool as well as warmth, the thermal development of the board made these tiny fractures take place arbitrarily, triggering the board failing.

Along with the basic Tg as well as Td worths, the thermal efficiency specifications of the substratum product likewise have the thermal development coefficient CTE. There are CTE in the X/Y/Z axis instructions.

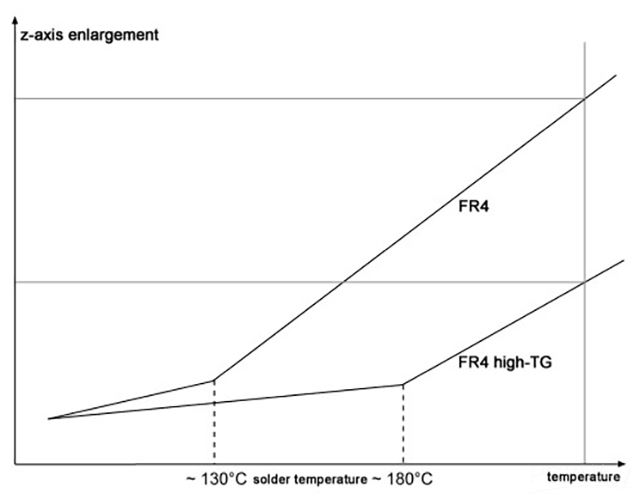

The CTE of the Z-axis has an essential impact on the dependability of the PCB. Given that the plated openings permeate the Z-axis of the PCB, thermal development as well as tightening in the substratum will certainly create distortion and also plastic contortion of the plated openings, as well as additionally flaw the copper pads on the PCB surface area.

The CTE of the X/Y axis comes to be really crucial in SMT, particularly when chip range product packaging (CSP), as well as chip straight installing, are made use of, the significance of CTE is much more noticeable. At the same time, the CTE of the X/Y axis will certainly likewise influence the internal attachment and also the anti- delamination capability of the copper clothed laminate or PCB. Specifically for PCBs making use of lead-free soldering procedure, the X/Y axis CTE worth in each layer is specifically essential.

So, does it imply that the greater the Tg worth of the substratum, the far better the board? In numerous conversations regarding the Tg worth, it is usually thought that a greater Tg worth is constantly beneficial to the substratum, however, this is not constantly the instance. It can be identified that for a provided material system, the high-rate growth of the substratum with high Tg worth will certainly begin reasonably late when heated up, while the general growth has a whole lot to do with the kind of product. A substratum with a reduced Tg worth might reveal a smaller sized total development than a substratum with a high Tg worth, which is mostly pertaining to the CTE worth of the material itself, or the enhancement of not natural fillers in the material formula to lower the CTE of the substratum.

It must likewise be kept in mind that for some low-end FR-4 products, the substratum with a typical Tg worth of 140 ° C has a greater thermal decay temperature level Td worth than the substratum with a conventional Tg worth of 170 ° C.

As we discussed, Td is an essential indication for lead-free soldering. It is typically advised to select a bigger Td worth, and also premium FR-4 usually has both high Tg as well as high Td worths. Additionally, substratum with high Tg worths have a tendency to be much stiffer and also weak than substratum with reduced Tg worths.

As a whole, as the Tg of the substratum raises, the qualities of the circuit card such as warm resistance, dampness resistance, chemical resistance, and also security will certainly be boosted.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

fenjgie

Tg (glass transition temperature) is the basic material parameter of temperature (°C). It defines the temperature at which the substrate becomes mechanically unstable. Tg is the temperature value that guarantees the mechanical stability of the PCB during the life of the PCB.