Support Team

Feedback:

support@nextpcb.comVapour reflow refers to an advanced PCB soldering technology that uses an inert liquid with a high boiling point. In recent years, this technology has become popular among large PCB assemblers. To solder electronic components to the PCB, manufacturers usually require high temperatures. This is a complicated process, and as electronic components become smaller and smaller, it becomes more challenging. Vapor reflow soldering ensures that the PCB board and its components will not be exposed to temperatures higher than necessary. Therefore, the parts will not overheat. This welding process provides ideal detail wetting. In addition, the entire welding process is performed in an inert atmosphere. Finally, PCB assemblers obtain the highest possible PCB soldering results.

Convection reflow furnace usually occupies a large area, so it occupies a large area in the factory. Although each heating zone has its own temperature control, engineers often face challenges when refluxing dense circuit boards in a convection reflow furnace, because it is impossible to control the temperature at a single element level.

The production line of the printed circuit board is usually placed in the convection reflux between the line and the SMT assembly equipment furnace, thus allowing relatively high throughput without additional processing. However, each product needs its own backflow curve, which the engineering team must create before starting production.

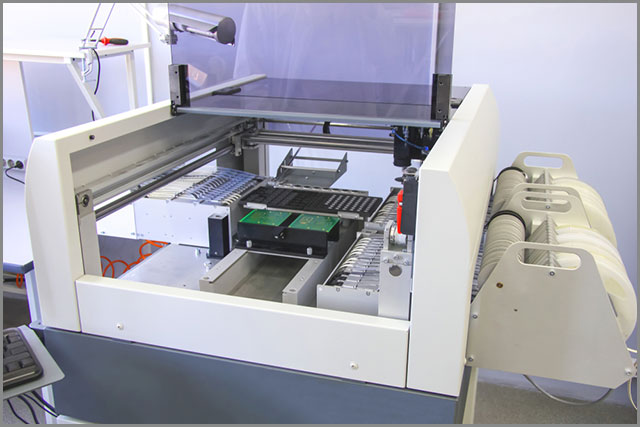

Unlike convection, this type of oven uses condensation or vapor phase welding. The steam comes from boiling perfluoropolyether, an inert heat transfer liquid. Compared with the convection reflow soldering furnace, the gas phase reflow soldering furnace occupies a much smaller area, and the PCB assembly moves vertically up and down rather than laterally.

When the component is located in it, the steam layer transfers heat to the PCB and related components. High heat transfer rate, good wettability, much less power input required. This process produces a small temperature difference between components with different thermal qualities on PCB. This makes the process very suitable for densely populated PCB.

In the gas phase furnace, the limitation of physical temperature can reliably prevent the overheating of any parts in the welding process. Because steam has a higher density, it is heavier than the surrounding air. This allows the welded parts to remain sealed in a neutral atmosphere. For example, an inert fluid boils at 230 ° C and forms a vapor layer above it at 230 ° C. However, the air above the gas phase will not heat more than 50-80 ° C.

The heat transfer fluids used in modern gas-phase reflux furnaces, such as perfluoropolyether, do not contain any CFCs or other harmful components that may restrict the transportation and storage of these fluids. Its main performance is excellent chemical resistance and heat resistance, high electrical insulation performance, non-toxic, low viscosity, no flash point or ignition point.

Vpr process relies on three different layers, which provide ideal conditions for top-level welding. These three layers are basic fluid layer, steam layer, and preheating zone.

In the basic fluid layer are the chemicals you heat to provide the necessary steam for welding. In order to obtain satisfactory results, it is best to choose the liquid with appropriate quality. We have outlined some of these features.

The actual welding process of steam layer treatment. The advantage of the steam layer is that there is no temperature fluctuation. This means you don't have to worry about overheating components.

Preheating layer helps to avoid welding defects. When you hover the PCB directly over the vapor layer, actual preheating occurs. Keep in mind that there are many preheating techniques depending on the machine you are using.

The main disadvantage of the gas phase reflux process is that it requires more manual operation than some other alternatives. Therefore, the VPR process is more suitable for mass production, which will affect the potential throughput. There are gas-phase systems that cater for mass production, but they tend to cost more than most convection ovens. Another disadvantage of gas-phase reflux technology is that it is more time-consuming than other solutions.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now