Support Team

Feedback:

support@nextpcb.comIn the Spring Festival of 2020, the unexpected outbreak of the COVID-19 (Corona Virus Disease 2019) disrupted the domestic life and economic development in China. The whole country has jointly combated the epidemic and taken a series of measures to avoid large-scale population movement and gathering. The electronics industry was directly affected by this.

From February 4, the Elecfans conducted continuous questionnaire surveys on the resumption of production and epidemic conditions of the upstream and downstream companies in the electronics industry chain. The surveyed companies involved IC design, semiconductor components manufacturers, foundry, and packaging testing, the agency distributions of electronic components, as well as automotive electronics, instrumentation, communication equipment, medical electronics, and other enterprises.

The survey questions related to the progress of resumption of production, recovery of production capacity, upstream supply chain supporting, downstream customers, and market demands. Based on the survey, the views of Elecfans are as follows:

The infrared thermometers are in short supply, driving a surge in demand for infrared sensors and other components.

Since the outbreak of COVID-19, medical equipment related to the detection and treatment of the virus has been very popular. The equipment includes hand-held thermometers, infrared thermometers, infrared imaging monitors, CT imaging equipment, ultrasonic atomization equipment, and vital signs equipment. The strong demand in the medical market has driven a significant increase in demand for electronic components, especially the need for the infrared sensors surged in the first quarter. According to surveys by Elecfans, the demand for infrared sensors is the most significant, accounting for 28%; Followed by processors and power chips, accounting for 19% and 15%, respectively; the PCBs and memory chips accounted for 12%. Passive components accounted for 8.7%.

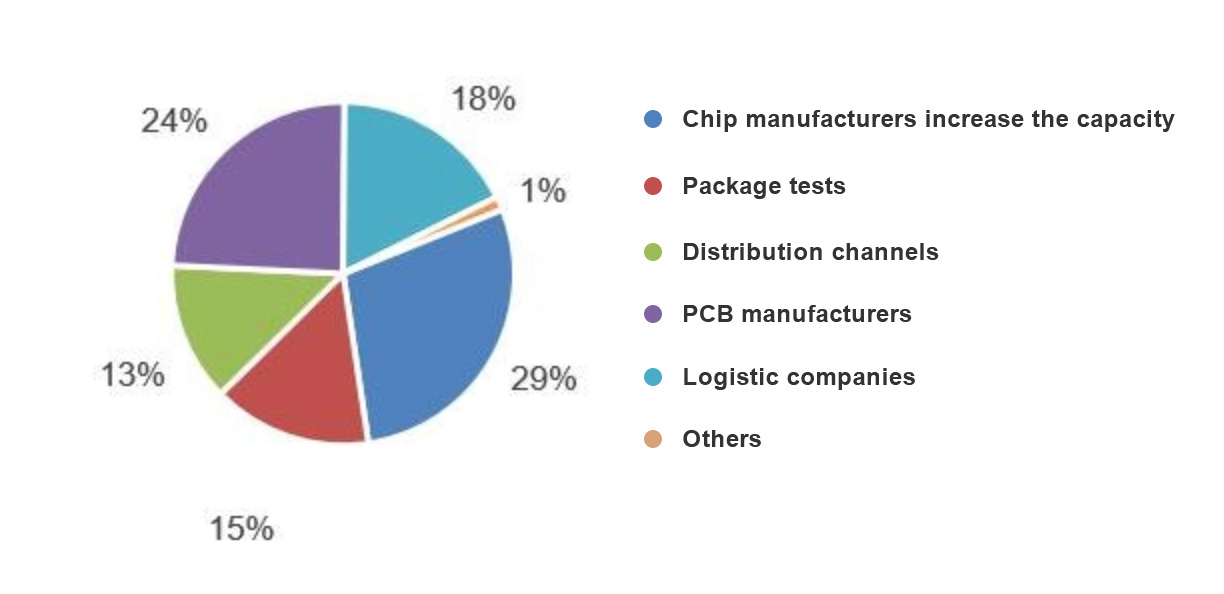

The direct impact of the epidemic on the electronics manufacturing industry was the delayed work resumption after the Spring Festival. According to the survey data from Elecfans, chip factories were the most eager to resume work, accounting for 29%. MCU factory has urgently urged orders of 8-inch wafer foundries due to the recent surge demand for ear thermometers, medical products, and related testing equipment against the virus. The traditional peak season for consumer electronics in the second quarter and the booming of short-term medical products orders, causing the urgent need to increase the capacity of chip manufacturers in the supply chain; Secondly, PCB manufacturer resumption is quite noticeable, accounting for 24%. Logistics companies and package tests rank the third and the fourth, accounting for 18% and 15%.

Since China is a big electronic manufacturing country, although the epidemic has suppressed consumer electronics demand for a short time, the market will have a strong need for consumer electronics, 5G, AI, and chip products in the future. The survey of Elecfans finds that there are four major impacts on the supply chain of enterprises by the recent epidemic:

1. 31% of enterprises reported that logistics and express delivery were not smooth, resulting in material shortage;

2. 25% of enterprises said that there are too much temporary demands, resulting in the lack of inventory materials;

3. 24% of the enterprises indicate that their market has not changed, but the original supplier’s inventory is not enough to cause a shortage of materials;

4. 15% of the enterprises said that the epidemic had affected the industry’s supply chain, resulting in the slowdown in the development of new products for engineers.

More than 60% of enterprises have resumed production, and chip production efficiency will be significantly improved.

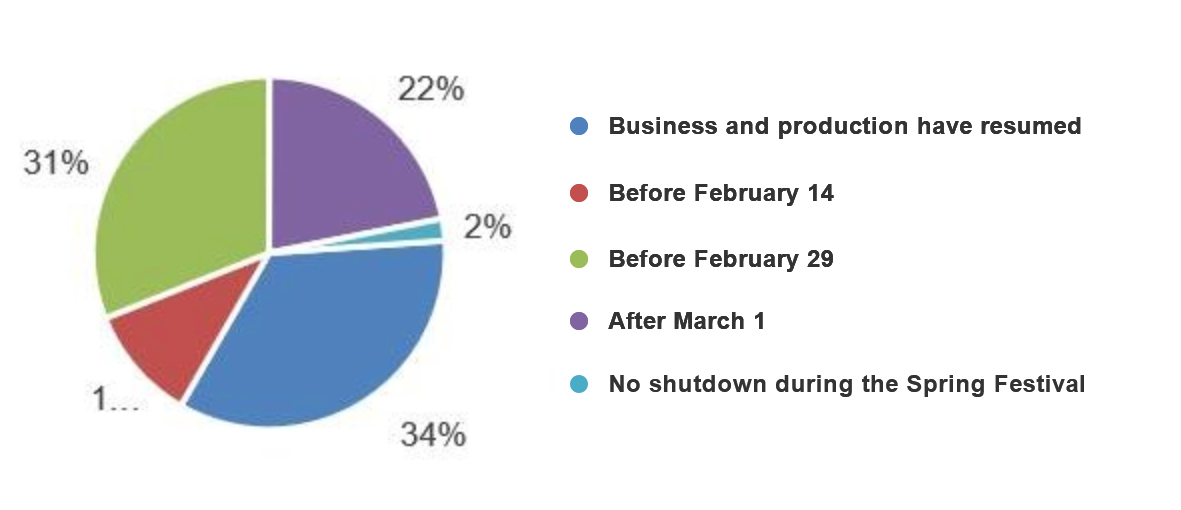

By March 2, the COVID-19 had been effectively controlled in China, except for Hubei Province. The resumption of business is crucial to the development of the local economy. According to the survey of Elecfans, 76% of the enterprises have resumed business and production. Among these, 45% of the enterprises resumed operations before February 14 and 31% before February 29. And another 22% will return to work after March 1.

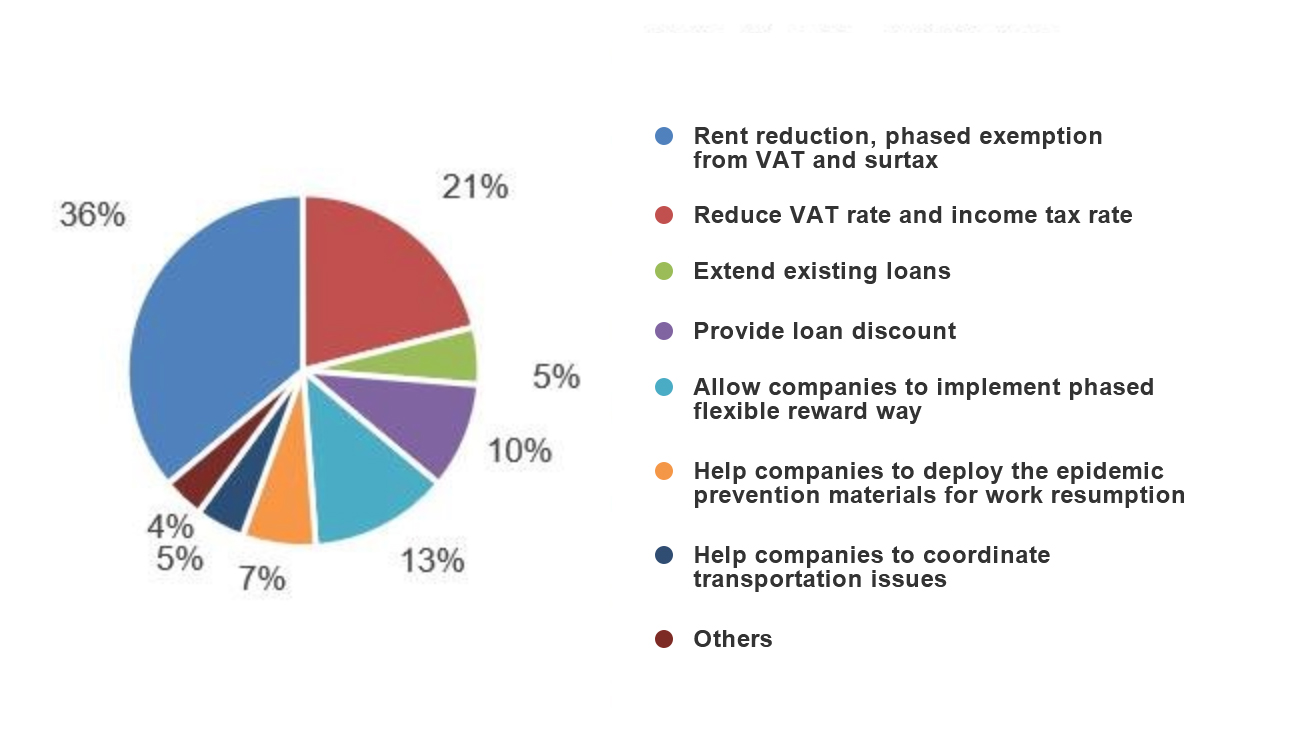

Against the epidemic, electronic manufacturing enterprises need the following help most:

l 36% of enterprises hope to be supported by rent reduction and exemption from VAT and surtax in stages;

l 21% of enterprises hope corporate VAT rate and the income tax rate will reduce;

l 13% of enterprises hope can implement phased flexible reward ways;

l 10% of the enterprises hope discounted interests, and 5% want the existing loans will extend.

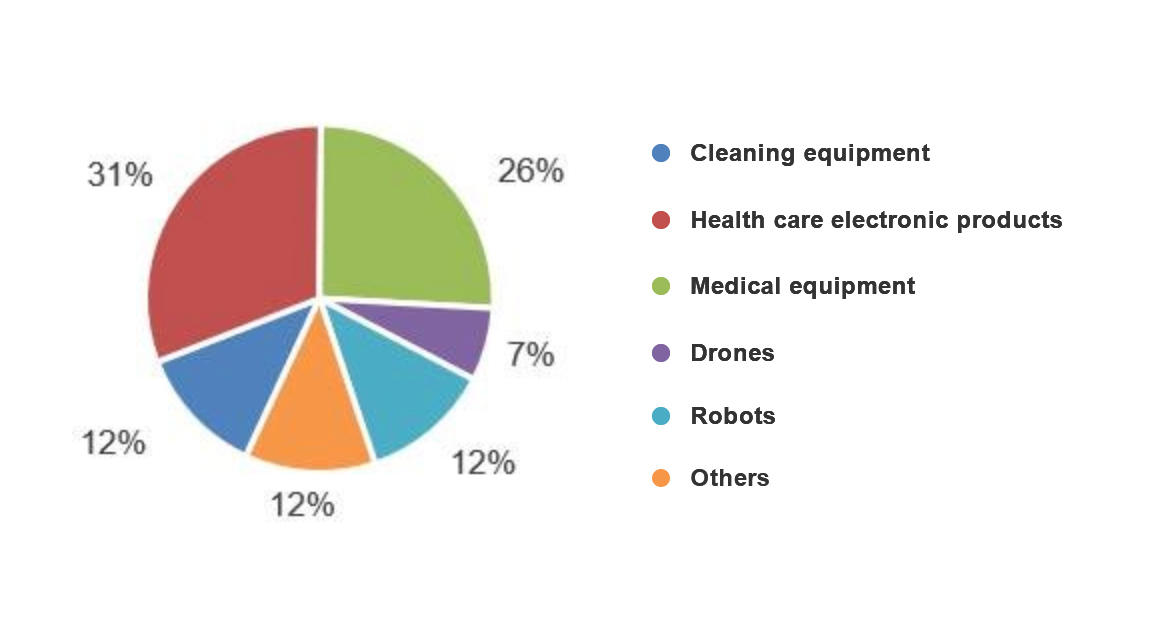

Nearly 70% of electronic enterprises are preparing to develop new products for the medical and health industry.

The epidemic had a considerable impact on retail, tourism, catering, transportation, and manufacturing, but it has also provided opportunities for the development of the medical and health industry. According to the prediction of international analysis agency, the GDP of the pharmaceutical and health industry in 2020 may add about 450 billion yuan. Masks, gloves, medical testing equipment, some proprietary Chinese medicines, and vaccines are favorable industries. Combined with the current epidemic situation, electronic manufacturing enterprises are exploring new product development space in four sub-areas.

l 31% of enterprises have plans to research health care electronic products;

l 26% of enterprises will produce medical equipment; 12% of enterprises plan to get involved in robots and drones;

l The enterprises that develop cleaning equipment and robot-related products account for 12%, respectively.

Conclusions:

The outbreak of the COVID-19 has brought a significant impact on China’s economy. China is a big manufacturing country. Therefore, electronic enterprises in China affected obviously. First, the demand side has changed dramatically. In the first quarter of 2020, the demand for smartphones and PCs decreases, but the need for tablets and network servers significantly increases. However, the smart medical equipment is in short supply, especially infrared thermometers. These lead the component manufacturers to update product plans, such as increasing the productivity of MCU and infrared sensors.

Secondly, the delayed resumption of enterprises affects the release of production capacity. However, due to the positive situation of China's anti-epidemic in early March, the resumption rate of semiconductor enterprises and other component manufacturers reached 70%. The production capacity is increasing continuously. And the resumption rate of packaging enterprises, including Changdian technology, has reached 80%, which can fully support the various market demands in the second quarter. The market shipment volume will increase soon.

Besides, the epidemic has had a huge impact on retail, tourism, catering, transportation, and manufacturing, but also gave birth to opportunities for the development of the medical and health industry. Many electronic enterprises target R & D plans for health care electronics, infrared imaging equipment, and quarantine detection electronics.

Finally, the government and the credit department have also introduced various preferential policies to help enterprises cope with the difficulties of the capital chain. We believe that the capital flow of enterprises will be better with the improvement of market sales.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now