Support Team

Feedback:

support@nextpcb.comWhat is the reliability?

Reliability refers to the ability of the product that completes the specified function under the specified condition and requirements. For end products, the higher the reliability is, the higher the guaranteed usage will be.

The reliability for the PCB means the “bare board” can satisfy the production requirements of the subsequent PCB assembly. What’s more, it also refers that within a certain period the “bare board”can be in normal operation under specified working environments and operating conditions.

How does the reliability become the focus of society?

In the 1950s, during the Korean War, 50% of American electronic equipment has failed in the storage stage, and 60% of airborne electronic equipment cannot be used after shipped to the Far East.

In 1949, AIEE established the first professional organization that studies the reliability-Reliability and Technology Group.

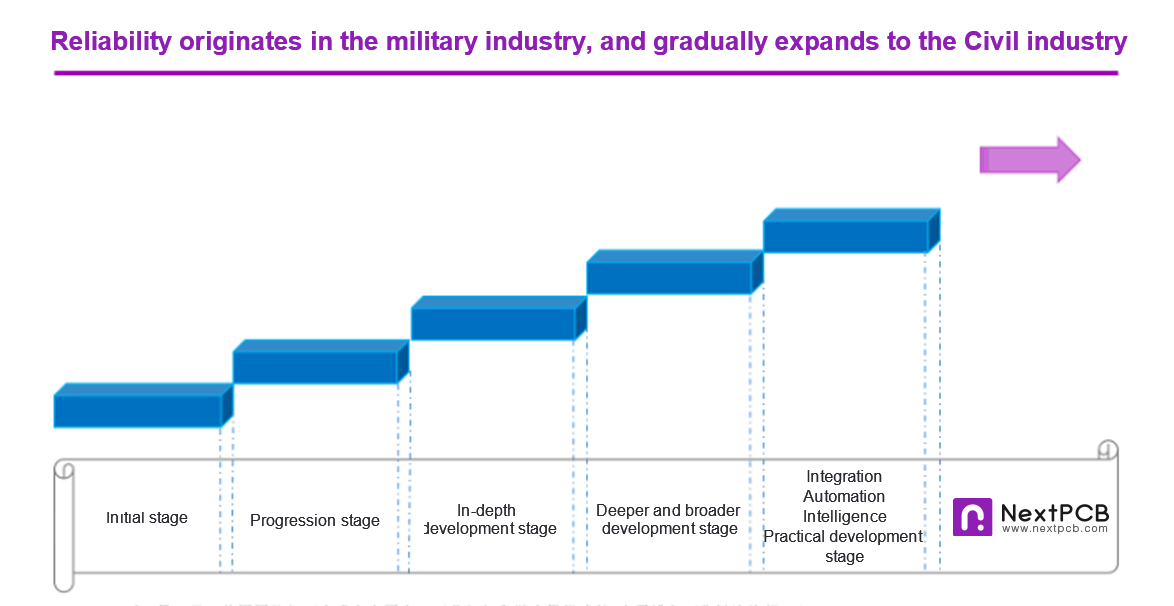

In December 1950, the USA established an exclusive committee that focuses on the reliability of electronic equipment. The military, weapon manufacturing companies, and academia have begun to intervene in reliability research, and by March 1952, they had proposed advice with a profound impact. The research results were first applied to the aerospace, military, electronics and other military industries, and then gradually expanded to civilian industries.

In the 1960s, with the rapid development of the aerospace industry, reliability design and test methods were accepted and applied to avionics systems. Reliability engineering has developed rapidly!

In 1965, the United States issued the "System and Equipment Reliability Outline Requirements". The activities of reliability engineering were combined with traditional design, development, and production and it obtains better benefits.

In the mid-1970s, the life cycle cost of the US defense weapon system was outstanding. People are more deeply aware that reliability engineering is an important tool to reduce the cost of the life cycle. Therefore, the reliability factories have been further developed. People adopted the more effective design and test methods, which had driven the rapid development of failure research and analysis technology.

After the 1990s, reliability engineering has evolved from military-industrial enterprises to the civil electronic information industry, transportation, service, energy, and other industries, from professional industry to the common industry. The ISO9001 quality management system includes reliability management as an important part of the review. Furthermore, professional technical standards related to reliability have been incorporated into the quality management system documents.

Today, reliability management has been widely accepted by all kinds of industries in society.

Why is reliability increasingly valued?

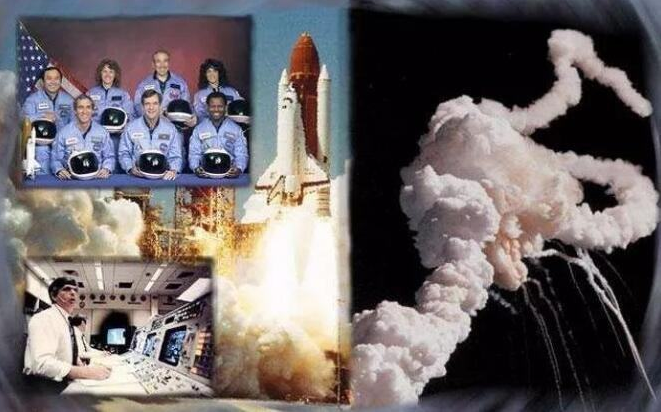

In 1986, Space Shuttle Challenger exploded after 73 seconds into its flight, killing all seven crew members aboard and losing $1.3 billion. Surprisingly, the root of the accident was due to a seal failure.

In the 1990s, the UL issued an article saying that PCBs produced in China caused a number of fires to the equipment. The reason is that China's PCB factories used a non-fire retarded board material, but they were marked with UL.

According to official statistics, the compensation of PCBA due to reliability failure accounts for more than 90% of the external failure cost!

Analysis of GE Company, for the equipment in the continuous operation of energy, transportation, mining, communication, industrial control, medical treatment, etc.

It is worth it to increase reliability by 1% even though it needs to increase the cost by 10%. For the reason that the company can reduce the maintenance fees, breakdown loss, and ensure life safety when PCBA has higher reliability.

Nowadays, in the world, competition between countries has evolved into a competition between enterprises. Reliability engineering is the threshold for enterprises to develop global competition, and it is also a magic weapon for companies to stand out in the increasingly fierce market!

Why the reliability of PCB should attract more attention?

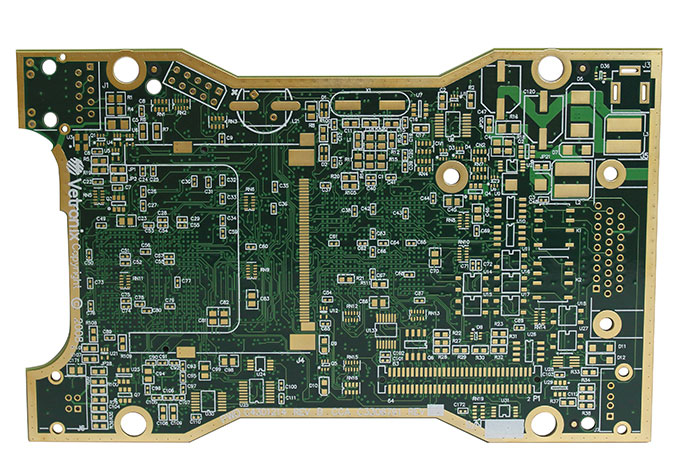

As the carrier of various electronic components and the hub of circuit signal transmission, PCB determines the quality and reliability of electronic packaging.

PCB with high reliability can play a steady function as the carrier to ensure a long-term and stable operation of PCBA. Hence, it can make sure the safety, stability, and service life of the end products. For this reason that the enterprise can enhance its competitiveness and reputation to expand its market share and improve its economic efficiency.

How to evaluate if the PCB has reliability?

High reliability is a practical science that combines "Engineering Technology" and "Management Art" so if enterprises want to produce PCB with high reliability they need to establish a whole set of the management procedure that includes“Standardized, efficient, collaborative and controllable”. Additionally, it needs the factories to control those important factors like engineering design, production material, manufacturing equipment, PCB capabilities, quality control, manufacturing environment, management system, team quality.

Therefore, it needs to make sure if the following control project has been under control before evaluating PCB has high reliability.

1.Prevention mechanism

1)Engineering design: Customers require identification, information management, automated operations, and professional skills. Work specification, process standardization, engineering production automation.

2)Manufacturing process: Systematically manage the control every objective, operation processes, and operation specifications

3)Quality Control Management: Standardize quality control standards, improve the quality assurance system, and assist the process to improve quality.

2.Process management

1) Quality and product safety system: IATF16949、ISO9001、GJB9001、UL、CQC、RoHS.

2) Engineering design: DFM specifications such as laminated structure, impedance, minimum line width, minimum spacing, minimum aperture, copper thickness. Production process design, material selection, manufacturability document design, etc.;

3) Production materials: Supplier review, material evaluation, raw material inspection, raw material storage, etc.

4) Manufacturing capabilities: Process capacity, production parameters, chemical liquid use, first FA, etc.

5) Equipment and facilities: Evaluation, daily check, schedule test, predictive maintenance, preventive maintenance, periodic maintenance, etc.

6) Operating environment: Dust-free, constant temperature, constant humidity,Illumination, etc.

7) Quality control: IQC, IPQC, IPQA, FQC, OQC, Reliability and test condition, etc.

8) Management team: Operation specifications, risk identification, problem analysis, strategy analysis, etc.

3.Quality assurance

1) Quality pass ratio: Real-time monitoring.

2) Quality reliability: Real-time/regular verification.

3) Quality consistency: Real-time/on-demand inspection.

4) The average duration of trouble-free use: Regular/on-demand verification.

4.Test verification

1) Signal performance: Impedance test, signal loss.

2) Heat resistance: Thermal stress, Tg test, TMA test.

3) Connectivity: IST test, Withstand current, Thermal shock.

4) Mechanical properties: Peel strength, Pull-off strength, Solder mask hardness, Adhesion.

5) Insulation performance: Withstand voltage test, damp heat insulation resistance, CAF resistance test.

6) Welding performance: Cleanliness test, solderability test.

7) Corrosion resistance: Chemical reagent for solder resistance, Gold finger porosity.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now