Support Team

Feedback:

support@nextpcb.comWith the quick advancement of scientific research as well as modern technology, digital items are regularly creating in the direction of miniaturization, agility as well as multi-function. As a result, PCB, as the service provider of digital elements, is bound to create in the direction of miniaturization and also high thickness. Typical PCB board surface area spread out a lot of resistance parts, to ensure that a lot of board area is inhabited. This is a major infraction of the brand-new generation of high-speed transceiver electronic info digital items, mobile little, light and also high-performance, multi-functional advancement of the legislation, as well as from the dependability of PCB setting up, the security of resistors as well as electric efficiency factors to consider, the assimilation of resistors is really needed. Today, it is increasingly more tough to mount a lot of parts on the published motherboard to fulfill these efficiency demands. In order to continually satisfy the demands of these advancement fads, most digital parts are easy parts, and also the proportion of the variety of passive parts to the variety of passive elements is (15-20) ∶ With the rise of IC assimilation as well as I/ O number, the variety of passive parts will certainly remain to raise swiftly. Installed resistance modern technology can well fix the above troubles, which is among the crucial innovations to recognize the assimilation of resistors. For that reason, installing a multitude of ingrained passive parts right into the published circuit card of high-speed products can reduce the line size in between the elements, enhance the electric features, enhance the reliable product packaging location of the published circuit card, minimize the welding factor of the published circuit card surface area, so regarding enhance the integrity of the product packaging as well as minimize the price.

Presence type of buried resistance

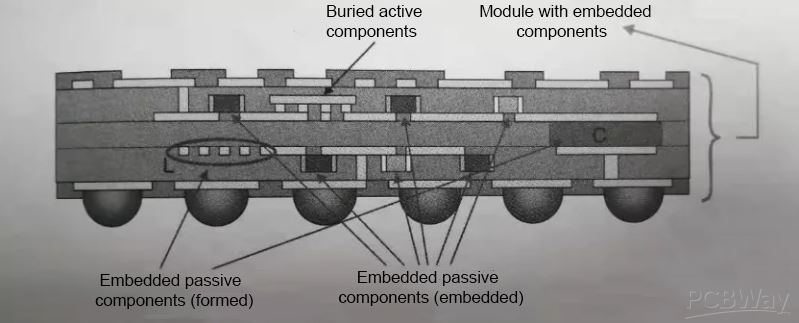

There are different buried resistance parts, however, there are primarily complying with 2 types: an ingrained buried resistance innovation is a modern technology that pastes different needed resistance parts right into the internal layer of the goal with SMT (surface area placing modern technology ), and after that installs the resistance elements pushed right into the internal layer of the parts. One is the unique resistance product via printing, engraving right into graphics, developing the called for resistance worth of the inner (exterior) product, utilizing the traditional multilayer PCB production procedure as well as various other parts of the circuit linked.

The above ingrained buried resistance and also both buried resistance types engraved right into graphics have the complying with typical benefits over the apart resistance:

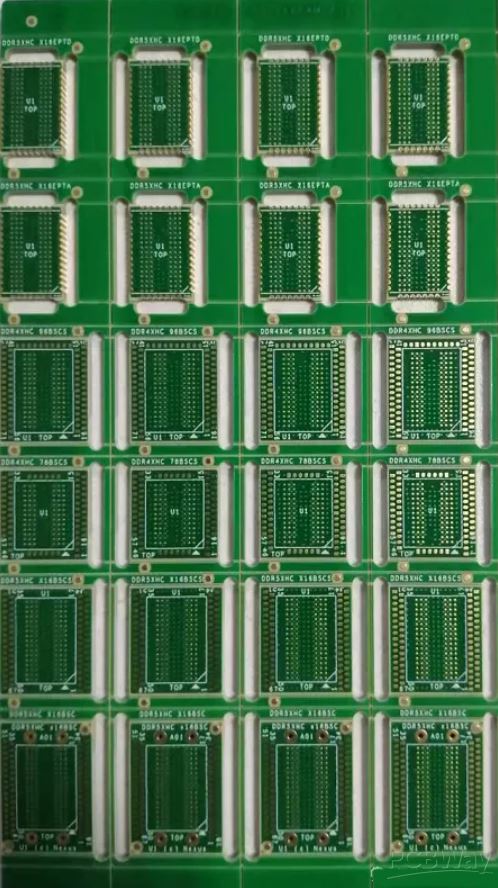

The ingrained resistance plate procedure of the 8-layer high transmission price product is generally based upon the ingrained innovation of resistance parts, as well as is finished by the broadband product of Panasonic Firm in Japan. The major problem of the ingrained innovation of resistance elements is that the resistance elements are very easy to be harmed throughout lamination. In view of this trouble, it is essential to determine the modification coefficient of the resistance core plate prior to pushing. The equivalent placement of the sustaining PP, as well as the light plate, is required to pre-drill the drill nozzle matching journalism filler as well as the elements (Number 2), and also the core plates, as well as PP and also light plates of each layer, are secured throughout pushing to stop layer discrepancy, slide plate as well as disclose resistance (Number 3) to stop the resistance from being harmed throughout pushing.

The primary handling problems are to regulate the positioning of the resistance and also stop the elements from being squashed. There are a collection of complicated procedures in the solitary side and also numerous high-speed PP light plate framework, such as gliding plate layer discrepancy, high-speed PP resistance opening dental filling + material plug opening saturation in the middle of home plate, tiny aperture steel fifty percent port very easy to reveal copper, opening drape, and also deep control backtracking.

With the fast growth of the digital sector, individuals' s need for a little, light, slim, high combination, and also high integrity digital items is boosting. Easy gadget ingrained innovation will certainly turn into one of the core competencies of PCB ventures. With the renovation as well as the technology of the initial innovation, it has actually developed right into a brand-new modern technology, which has superb applicability as well as marketing worth. The growth of the PCB market is the conjunction of possibilities as well as difficulties. Just by building up and also speeding up, can it appear, fulfill the expanding market need as well as win even more market chances.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now