Support Team

Feedback:

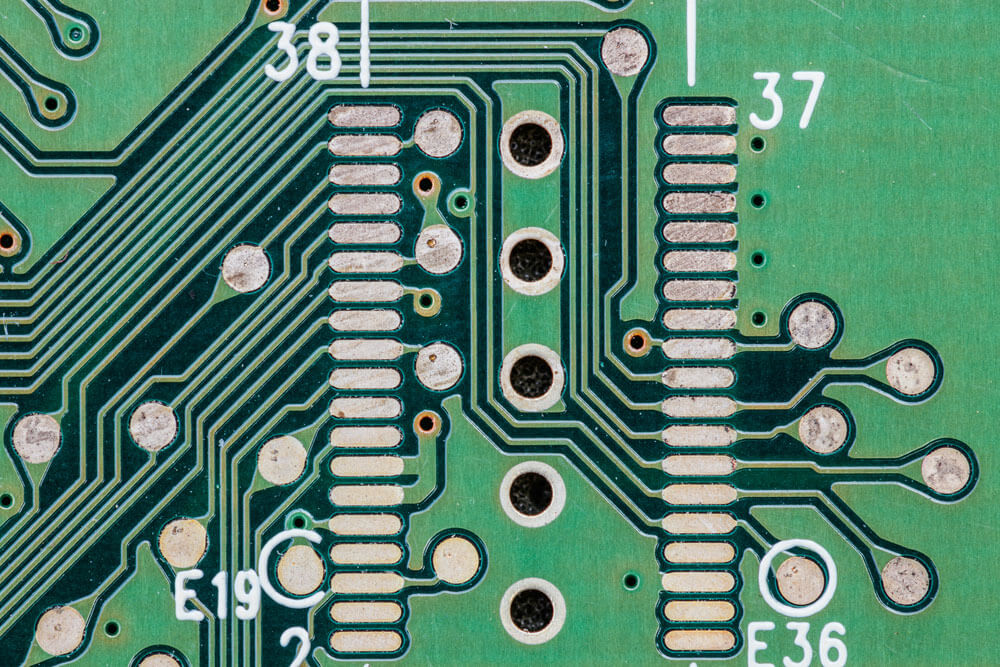

support@nextpcb.comA PCB via is a tiny hole drilled into a circuit board to connect or make an electrical connection between two or more layers or signal tracks. It is a copper-plated hole (usually by electrolysis, riveting, or inserting a tiny tube of conductive material inside the via) that allows the current to flow from one layer to another passing through the non-conductive PCB substrate (laminate).

Depending on the circuit board's application and requirements vias could be of various sizes and types. The circuit board may require a via that crosses all the layers to connect the top and bottom layers or a via that needs to connect two or more hidden internal layers.

The purpose of a PCB via is to connect two or more layers/signal tracks. However, PCB vias also serve heat dissipation in electronic circuit boards. PCBs produce a large amount of heat during their operational period, which can severely damage the board and cause circuit board expansion. In such cases to dissipate excessive heat vias are placed near heat-generating sources to transfer and spread heat over a large area to speed up the cooling process.

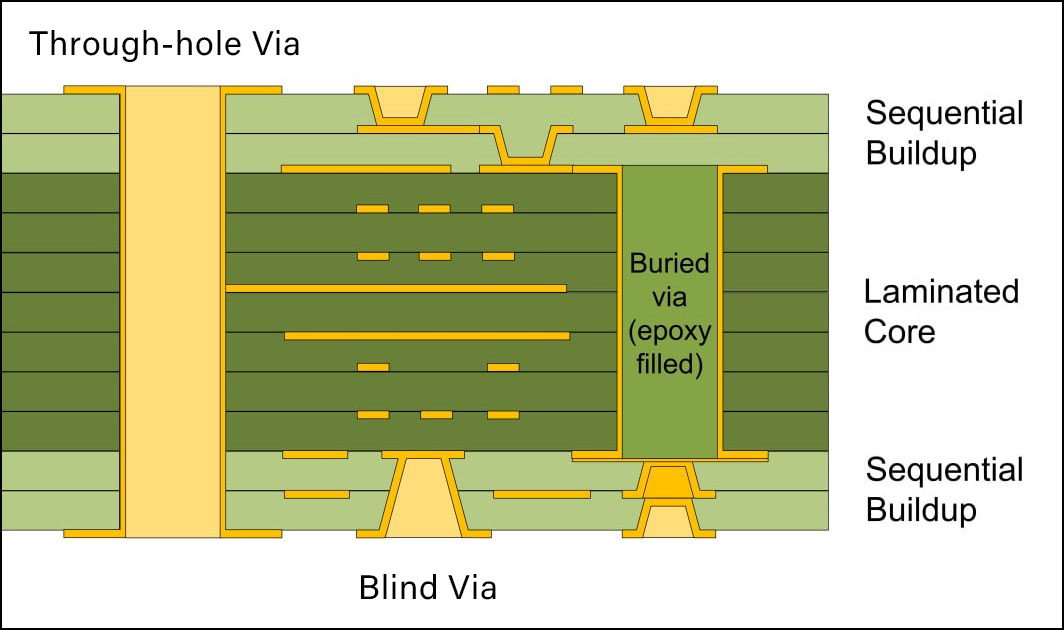

Based on the position and characteristics PCB vias are held in three groups.

This is the most convenient type of PCB via. It passes through all the layers of the PCB and connects the top and bottom layers as well as the internal layers of the circuit board if required. Through-hole vias have a larger radius compared to the other two categories. In addition, they are easy to manufacture as there is no need to accurately measure the depth. The manufacturer drills them the same as plated through holes.

Blind vias start from the top layer of the circuit board and go through the desired number of layers but do not reach the bottom layer and vice versa. They help connect an external layer of the circuit with one or more than one internal layer(s) without leaving a good amount of traces. Looking at it from a production standpoint, however, they create some complications as manufacturers need to measure the depth precisely to stop the drilling process and get the desired depth.

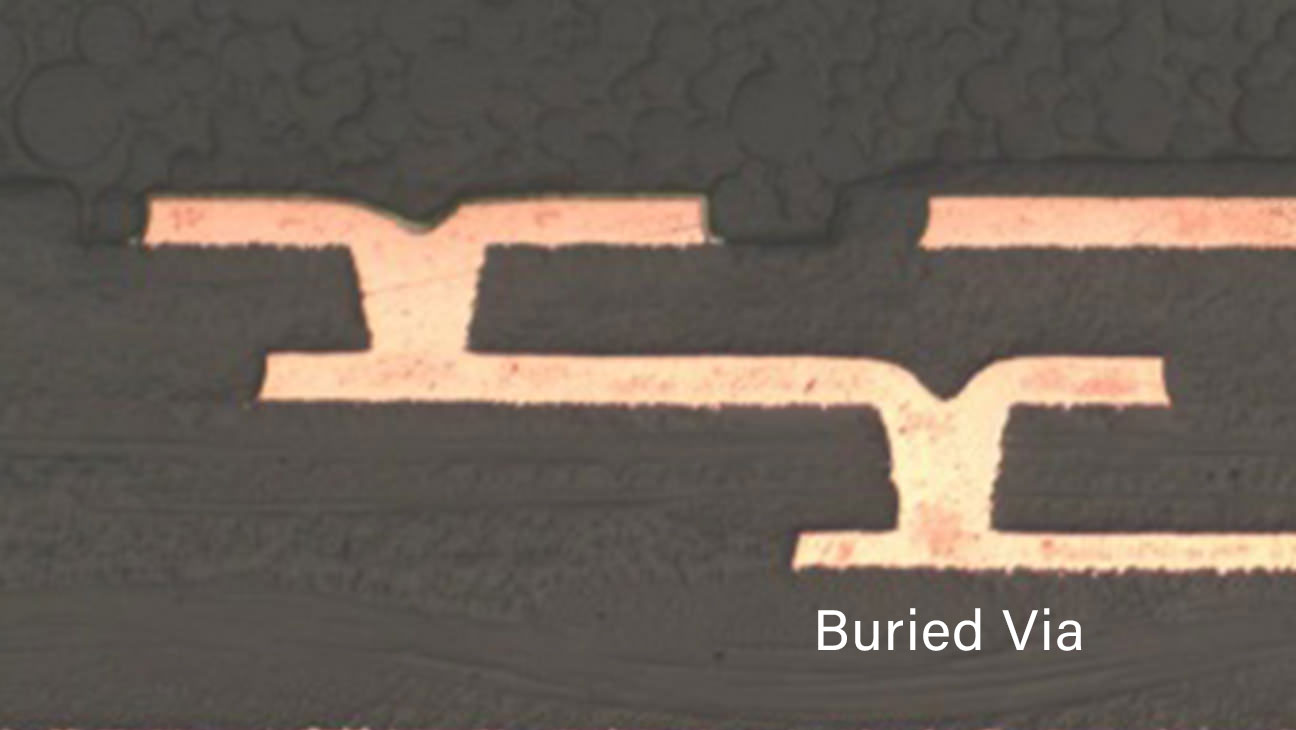

Buried vias are self-explanatory. You can not see from the top or bottom layer of the circuit board. They connect two or more internal layers without leaving traces on the external layers. On the manufacturing level buried, vias take a lot of time as each via required to drill and plated with a conducting material before the lamination process. Buried vias have also proven significant in reducing the PCB aspect ratio.

Microvias are a class of vias used exclusively on printed circuit boards with a high number of interconnections. They are characterized by their small diameter, typically 150 µm or less, and their cone shape, which greatly simplifies the internal wall plating process, and a maximum of 0.25mm depth. Laser micro-perforation is necessary to create holes of such small dimensions. Microvias have the advantage of reducing the size of the PCB and are particularly useful in applications such as BGA breakout and reducing crosstalk in audio circuits. However, micro-vias are not free from issues or defects that can compromise the reliability of the electronic board, such as ICD (InterConnect Defects) near the internal plating of the holes that can cause open circuits and other intermittent problems when operating at high temperatures.

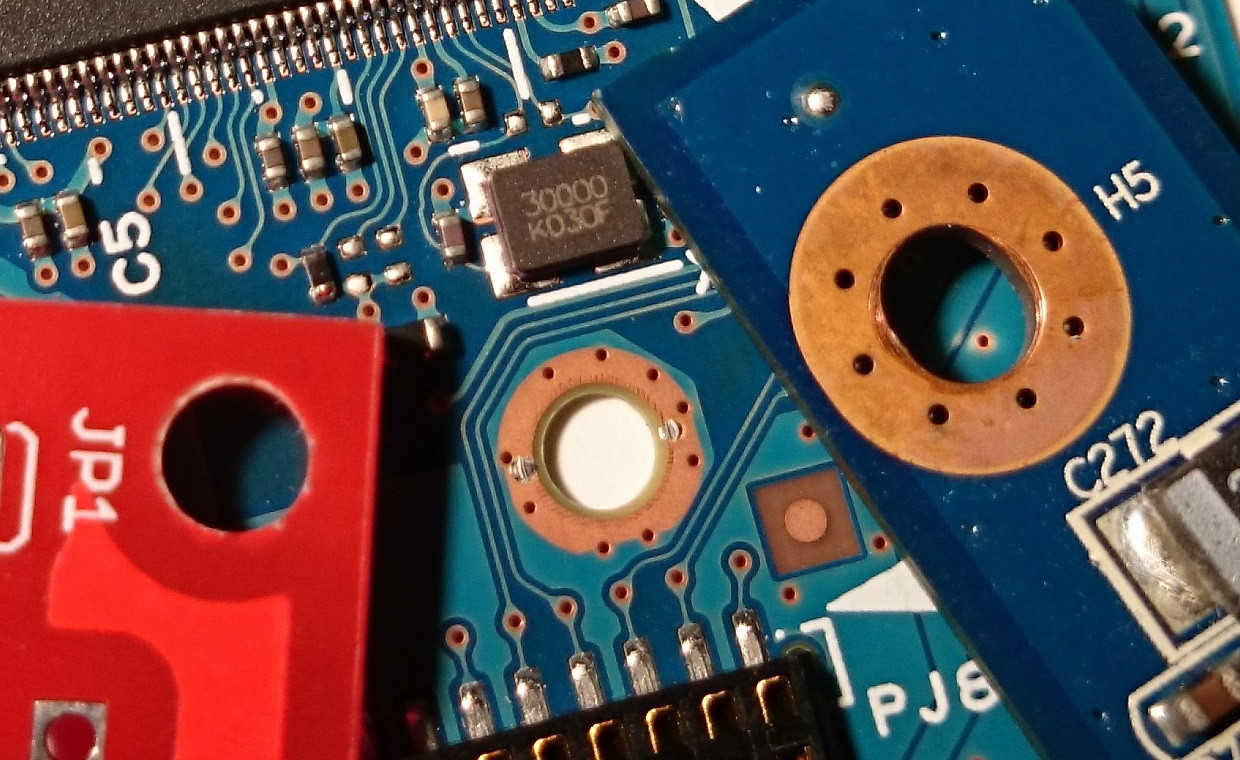

Thermal vias have to do with the heat. In printed circuit boards high power components like MOSFETs, power modules, transformers, diodes, etc produce a considerably great amount of heat that is excessively damaging to the circuit board. In such a case, to dissipate heat generated from such sources vias are placed to travel heat to a larger surface to increase the rate of heat dissipation.

Most of the PCBs in the market use FR-4 substrate due to its low cost and reliable properties. Expect its outstanding properties, it has potential heat resistance. Hence, placing thermal vias near (best if placed below) the active components and microprocessors or high-frequency components allow them to operate at a lower temperature. Along with the property of dissipating heat faster than most of the PCB substrates, there is an issue associated with thermal vias. They have some inductance. But it can be tackled by placing more vias in parallel and providing a defined lower inductance current return path.

For the closing note, thermal vias physically look like plated through holes. Their quantity on a circuit board can be concluded with modern PCB designing software. Running a thermal analysis of the board in different operating conditions can accomplish it.

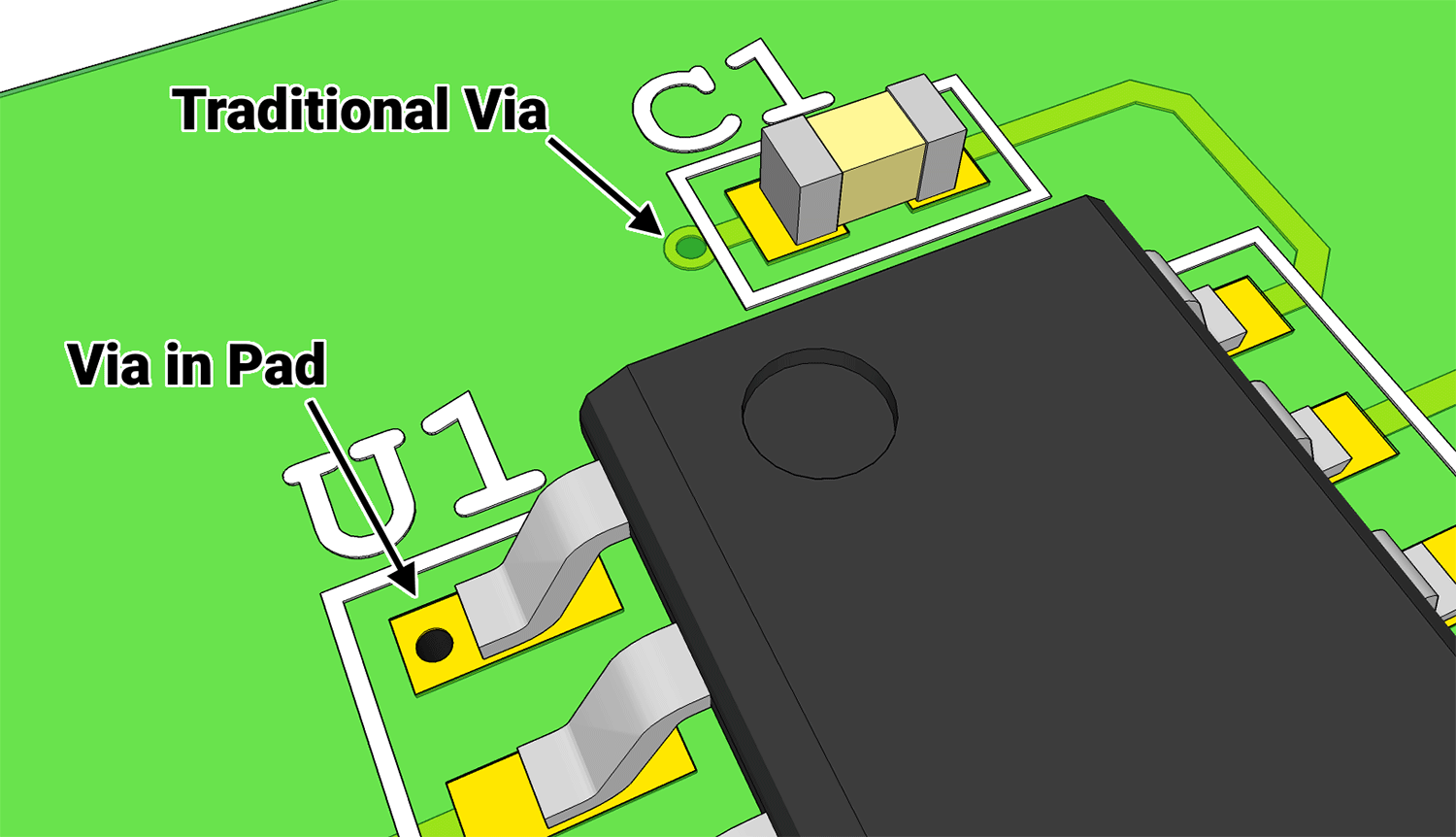

VIP or Via-in-pad technology draws attention toward a common PCB designing practice of incorporating vias in the active signal track. Via in-pad routing enables the utilization of smaller component pitch sizes and facilitates a considerable reduction in the overall size of the circuit board when compared to conventional PCB via routing.

Through Via in-pad technology, by utilizing Capping Process it is easier to produce high-density PCB designs without the enclosure of chemicals. This method also enables the incorporation of additional conductor traces for BGAs, offers better thermal management that aids heat dissipation, and defeats other constraints of the high-speed circuit boards, low inductance, for example, among other advantages.

Capacitance and inductance impact the functionality of the circuit board. They usually cause signal delay and poor signal integrity. These issues may be negligible for low to moderate-frequency circuit boards, but high-frequency circuits may suffer a lot. Hence a precise calculation of the capacitance and inductance generated by the vias is crucial.

To calculate Capacitance and Inductance we have:

Capacitance: $$C=\frac{1.41 \times \varepsilon \times T \times D_1 }{D_2-D_1}$$

Inductance: $$L=5.08 \times h \times [\ln( \frac{4 \times H}{D_1} ) + 1 ]$$

where ε is the relative dielectric constant of PCB,

D1 is the diameter of the via,

D2 is the diameter of the anti‐pad,

T is the thickness of the PCB, and

H is the length of the via.

PCB vias somehow made circuit board manufacturing a little trickier. As in the case of buried vias the manufacturer has to drill the vias of each layer individually before the lamination process. It results in potential delays in manufacturing time. The higher the number of buried vias the longer it will take for the manufacturer to execute the further procedure which will surely add up to the manufacturing cost. However, blind vias are more complex as they require precise measurement of depth to achieve the desired deepness.

Along with the types of vias, their sizes do matter a lot. Thinner vias require modern machinery special labor and the latest laser technology to drill. Hence, the quantity of PCB vias is directly proportional to the cost. Whereas a large quantity of relatively smaller vias than conventional could do wonders for the manufacturing cost.

The selection of PCB via type depends on the electrical and mechanical requirements of the circuit board. We know that the through-hole vias are cheaper than the blind and buried vias but they can not be used for every purpose. In this article, we have described each PCB via type in a comprehensive way which will help you to understand Via types and their functionalities. We would highly recommend you go through the article to develop a rigid understanding of the PCB Vias so that you can select the best Via – One of the basic building blocks of the printed circuit board, for your project.

NextPCB has been offering a one-stop solution for PCB manufacturing, assembling, and testing services for over 15 years. We at NextPCB use the latest technology with every possible approach to carry out complex to high-level Interface Circuit Boards and offer a wide range of PCBs, including metal-core, LED, High-frequency, High-Speed, Waterproof PCBs, and PCB Cameras.

We at NextPCB offer a standard and customized PCB of up to 20 layers with the desired thickness and are willing to incorporate all unique requirements.

Geographically we are located in China. But in a decade and a half, we have built a trustworthy relationship with our worldwide clients.

Get in touch with us to learn about our PCB capabilities and to get an instant PCB quote.

Luckily the NextPCB provides a $0 Free 1-4 layer PCB Prototype service.

A PCB via is a crucial component in circuit board design that helps to connect two or more layers/signal tracks and provides heat dissipation. There are different types of PCB vias. Including through-hole, blind, buried, micro vias, and thermal vias, each with its unique features and applications. The two most important categories of PCB via are Microvias and Thermal Vias. They are important from both electrical and mechanical aspects. PCB vias take almost up to 10% of the manufacturing cost which can surely increase depending on the quantity and type of the vias. Overall, the PCB via plays is a basic building block of the PCB and plays a vital role in the performance, reliability, and durability of electronic devices.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now