Support Team

Feedback:

support@nextpcb.comIn the last article entitled "Application of industrial robot in PCB industry", I said: "automatic equipment + industrial robot operation" will replace the traditional production mode of "automatic equipment + manual operation", which will become the transformation and development trend of PCB industry. Robots will replace many working humans in the future, just as innovative agricultural equipment replaced humans and horses during the industrial revolution.

As market research firm tractica released a report in 2016, "it is predicted that the annual revenue of global AI products and services will increase from $643.7 million in 2016 to $36.8 billion in 2025, a 57 fold increase in this period. By using machines, large companies describe computers and computerized devices that can be programmed to learn, build robots, and deploy more and more robots driven by machine learning algorithms in factory workshops, so that they can adapt to the people they work with.So how are industrial robots designed? Let's take a look.

The technologies and processes that roboticists use to bring electrical and mechanical projects into life are as important as the tools they choose. Although the design process seems to be linear, new considerations arise at every turn, which roboticists must then input into the design (perhaps at the beginning).

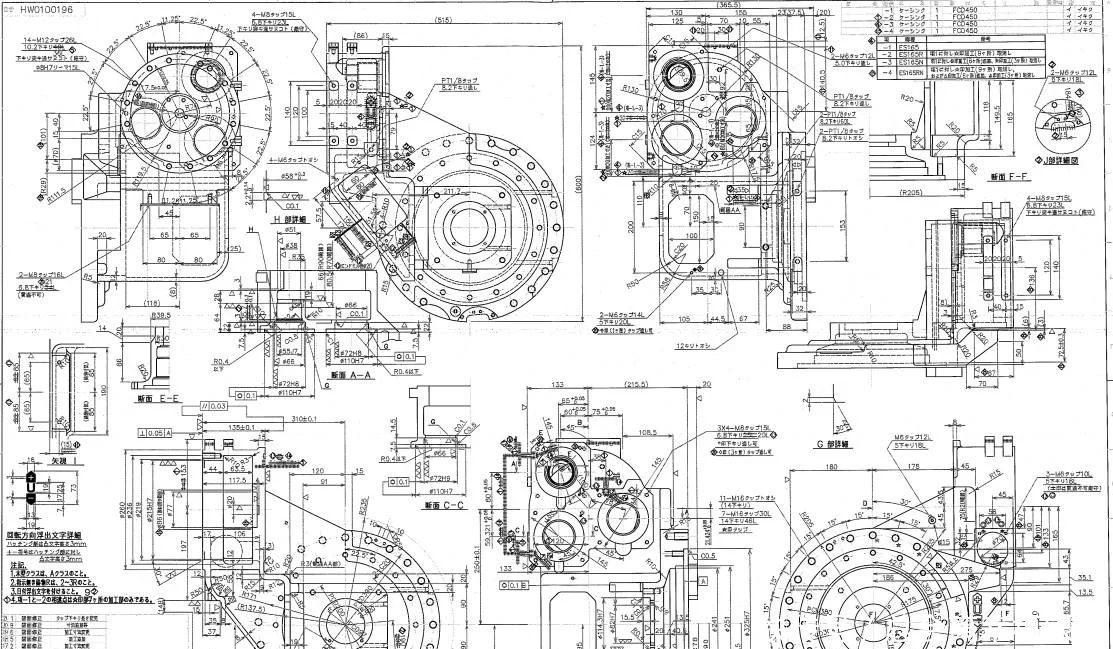

When the sculptor chooses his own tool, the robotic also chooses his own design platform. "I use SolidWorks every day for solid modeling. Such mechanical CAD tools are essential for designing systems as complex as most robots." said Derek Scherer, Robotics and Automation Engineer at Golem Group LLC, who designed the robotics technology for the film: "The Hobbit: An Unexpected Journey", "Human Steel" and "Elysium". SolidWorks brings a deep dimensional and mechanical understanding of surfaces to robotics projects. When a desktop engineer cuts a sphere in half in SolidWorks, the platform has the same understanding of the qualities and characteristics of a human half of a sphere in 3D space. "SolidWorks generates diagrams and tolerances-everything the shop needs is necessary to make the final design," Scherer said.

Blender is a popular physical animation tool, a popular choice for animation presentations, and it's free. "As long as you see an animated robot on YouTube or a company website, it is possible that they are using Blender," said DJ Sures, president of EZ-Robot, a personal and educational robot platform manufacturer. Blender is a 3D CAD design software package that enables engineers to load design files, animate any design, add effects and visualize robot projects. Sures said: "Blender combines real physics with animation to simulate your robot, so you can verify that it is working as expected."

Another tool, Linkage, is a mechanical simulator that enables users to create links and their connections, and move parts in the simulation to see how they work together. "This is useful for finding major design flaws as early as possible," Scherer said. RobotsLAB, the manufacturer of RobotsLAB BOX educational robots, uses Autodesk Inventor to design robotic mechanisms. Although the functions of this design tool are diverse, designers must still consider the limitations of manufacturing technology. “If you want to cut parts with metal, you must remember that the cutter head can only punch holes in one size, or you can punch holes on the bottom surface of the part,” said Ryan Wood, Chief Engineer of RobotsLAB. . Each building material has its own manufacturing restrictions.

RobotsLAB uses Autodesk Inventor to model the unbuilt components. When considering how to use sensors or motors to purchase a robot, designers will introduce the model into CAD software to determine where to place it and consider how to place parts and equipment around it. Some companies provide CAD models of the parts they sell. "But we may have to use the mechanical drawing of the unit to model it in our CAD software. Or, we can buy parts and create models from them," RobotLAB's Wood said. According to Wood, if motors or other components take up too much space on the robot, robotics experts may try to redesign other components or enclosures where all components fit, or they may try to choose a smaller size motor. . But these components and design choices also affect the robot and its functions. Wirz said the design process starts with a paper design using spreadsheets. In fact, Microsoft Excel is one of Wirz's most valuable electronic design tools. "I use it to complete all design equations, calculate resistance and capacitance values, and complete all theoretical calculations. Microsoft Excel enables Wirz to easily record the electronic design process with changes in design choices (such as changes in environmental operating temperature specifications), but If the customer says:'We told you we want to work at 30°C, but we want to work at 20°C', I can change the number in Excel and see how it affects the design. Wirz completed the theoretical design and mathematical design equations of the circuit engineering design, and input the circuit into the schematic capture tool to add transistors, resistors and traps. He makes the circuit in DxDesigner, which connects all the pins together. The Mentor Graphics HyperLynx Analog add-on software used with the DxDesigner schematic capture software facilitates simulation at this time. "Then I exported it to a PCB tool to translate the theory into physics, design the circuit board and determine where the chips and components dropped," Wirz said. After designing the circuit board, the desktop engineer will want to integrate the circuit board with the mechanical design. "For this, I exported the PCB design to Creo, which is PTC's mechanical 3D design software package," Wirz said. Creo enables engineers to integrate physical objects with robot designs. He said: "I can make a 3D model of the housing and print it on a 3D printer to check whether the circuit board is suitable."

PCB Design Analysis Software-NextDFM

The designers of RobotsLAB consider the entire robot system, its electronics, computers, and machinery together, and how they affect each other when designing in any one of them.

"Suppose you need a robotic arm to pick up a 2-pound thing. Weight. The gripper you designed is also heavier. Now, the basic joints of the arm need to lift the weight and weight of the arm and the jig. This makes us more interested in electronics The power capability of the equipment is questioned." Wood said. If the performance of the robot requires more energy than the electrical specifications support, and to avoid power failures, for the safety of other people in the robot environment, more powerful electronic equipment may be required. Similarly, in order for the end effector to have a greater grip, the robot hand may have to consider using a larger and more powerful gripper motor. These motors may require the use of stronger motors on the rest of the arm to lift the extra weight, which in turn may lead to rethinking which electronic devices can support the design.

In an example, Amazon employs more than 100,000 robots in its warehouses to efficiently move goods, while its warehouse labor force has increased by more than 80,000 people. Take Amazon as an example. Humans pick and pack goods (there are more than 480,000,000 items on the "shelf"!), while robots move orders in giant warehouses, radically reducing "the time required for workers to walk so that Amazon has become more efficient and labor-saving for pickers. "In addition, robots" allow Amazon to stack shelves like cars during peak hours because they no longer need human aisle space. Greater shelf space density means one More inventory under the roof means better choices for customers."

A French company, Evidence, worked with Deutsche Post to design and produce PostBot, an "electric robot" that can use artificial intelligence to follow every corner of the city to deliver up to 330 pounds of letters and parcels. The carrier navigates the entire transportation route and can overcome obstacles in any weather conditions. Amazon warehouse robots, but PostBot aims to relieve the pressure on postmen, who usually have to walk several miles in (increasingly) dense urban environments, to carry a lot of heavy mail. In the future, sending mail will seem like being in a park. Wandering, and PostBot does have to carry (move) hundreds of pounds of...Amazon packages.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now