Support Team

Feedback:

support@nextpcb.com

Turnkey PCB Assembly is the effective assembly process that provides cost-efficient and effective circuit boards with the shortest possible lead times. It uses internet-based software solutions including PCB manufacturers. It helps to develop the PCB quickly and effectively. Not only this, the major advantage of this assembly process is the cost-effective solution to help small businesses.

With a full turnkey solution, you can focus on designing your PCBs and leave the rest to the supplier. Assembling and testing circuit boards for products is made efficient and cost-effective with turnkey solutions. The shortest lead time is also possible when using this method. Turnkey PCB assembly includes beyond PCBA services for the creation of finished products. It includes:

The major benefit of the turnkey PCB assembly is any organization or business doesn't need to spend time on critical innovation processes and solving the assembly side. To assemble them skillfully, you don't need to look for the best component costs, go through a frustrating procurement process, and then spend time and energy finding them.

Before you can get the PCB quotation, you should provide some of the information to your turnkey maker. Below is the list of all the information that you need to provide before asking for the quotation;

Initially, provide the bill of Materials to your turnkey manufacturer. Most of the makers expect the BoM to document in Excel format. Excel provides a faster and relatively easier sheet of your product. Make sure that you provide complete details about the components and the designators.

Besides, the BoM contains the name of the manufacturer, component quantity, and part numbers. The manufacturer used all of this information during the SMT.

Gerber files are one of the most important things in the manufacturing industry. It describes the PCB images like copper, solder mask, drill data, etc. Many of the manufacturers accept Gerber files in various formats. It is required before the maker begins PCB board production. While some manufacturers also ask for the design file for assembling the turnkey PCB assembly.

The Centroid File (also known as the Pick-and-Place File) contains the coordinates, orientation, and pad information for all components on a PCB. This file is especially crucial for automated surface-mount technology (SMT) assembly, as it provides the positional data and rotation angles required for placing and picking components. The file typically includes the following information:

This file is primarily used for automated pick-and-place assembly, where the pick-and-place machine uses the Centroid File to accurately position components on the PCB, enhancing both assembly efficiency and precision. The format is typically CSV, TXT, or POS file.

Finally, the packaging and the shipping information are the final information that you should provide to your manufacturer. Proper packaging is a must since it will save your product from damage during transmission. Thus, if you seek top-notch packing services then you should provide all the details of packaging and shipping during the ordering process.

NextPCB ensures that qualified products are packaged using suitable protective materials to guarantee their safety during transportation. This includes anti-static packaging, shock-absorbing cushioning, wooden frames or crates, and moisture-proof packaging. Each packaging method is selected based on specific product characteristics, transportation environments, and customer requirements. By carefully choosing the appropriate packaging, NextPCB ensures that PCBA products are delivered to customers safely and intact, maintaining high standards of quality and protection throughout the shipping process.

After providing all the required information about the products, you can now ask for a quotation. There are several ways of getting quotes from your turnkey maker. The fastest and the most convenient ways of getting a quote are:

Online is the most convenient and fastest way of getting a quote. With the effective use of the internet, you can get all the information about your product and PCB quote. All most all PCB manufacturers have user-friendly websites that can provide information to their visitors.

Thus, if you want the fastest and more convenient ways of getting quotations, then the internet is the very first choice. You can get all the information regarding the price of your assembled PCB.

Another way of getting the quotation is by the online PCB assembly quotation method. With this method, pick and place machines can easily place the components on the PCB, PCB assembly helps you in finding out how much assembly will cost. The best way to do this is to search the internet for such information to get an accurate quote for ordering the board parts and assembly charges. The best way to do this is to find the information online.

The standard laminates, silkscreen, and solder resist method generates the best quality board. Precise pick and place which is an automated machine make the component placement. Besides, the fine reflow ovens archive the solder joints on each of the tiny pin parts.

During the initial project development stage, the turnkey assembly includes design reviews, which allow for identifying possible errors and correcting them. Faults at later stages take extra cost and time.

Production time decreases significantly in the turnkey assembly since it uses multiple component sources. In this assembly process, time saves as the manufacturer handles the entire process of PCB assembly.

Since, in turnkey assembly, the service provider is the only one who checks all the project updates. It takes on the responsibilities like communicating with the vendors, monitoring the testing line, tracking the assembly progress, and all. This helps in avoiding confusion with different vendors, improves the efficiency of the project, and thus saves time.

Cost calculation and analysis is the major factor in any startup. Besides, cost estimation for the manufacturer can help them develop a strong strategic plan for product development. The online quote provides all the details of the complete production of PCB manufacturing. Since the service provider handles all the inventory, thus the price gets lower when they order the component in bulk order. Thus, the price for turnkey PCB assembly decreases.

The turnkey PCB service provider offers customized assembly service along with various other services like debus, test, packing, and deploying to the customers, etc. They provide the complete package based on the customer's requirements. Thus, you can achieve all the ready-to-use products through this turnkey assembly service provider.

Manufacturers can perform additional services such as box build assembly and mechanical system integration during box build assembly, which is also known as mechanical system integration. Apart from the actual fabrication of PCBs, the process includes all other necessary tasks. Box build distinguishes PCB assembly from the final delivery.

All the inspections and tests leverage results from the box-build PCB assemblies. Designers should make sure that the PCB-making process is fine and is aligning with the desired specifications.

PCB assembly's built-in boxes involve numerous processes, including but not limited to:

PCBs manufactured by a turnkey supplier include all the electronic components required for the manufacture of the PCBs. A turnkey PCB assembly involves the procurement of all electronic components through the final assembly of the product. The manufacturer does not provide value-added services like the box build but does provide value-added services to customers. Therefore, designers who don't have time to assemble PCBs will benefit from this turnkey solution.

Partially turnkey PCB assembly involves the designer supplying the components, and board to the PCB manufacturers. It may be transformers, resistors, capacitors, or another type of circuit board component. Designers with a large inventory of electronic parts will benefit from this type. If not, the PCB assembly manufacturer would face delays in sourcing parts.

Working with one company relieves your engineer of the burden of managing multiple contracts. Keeping in touch with multiple people and organizations (especially those overseas) can be stressful, but this software eliminates some of the stress. Additionally, it minimizes the likelihood of software and manufacturing equipment incompatibilities.

For a single designer, the sourcing process is time-consuming. There is a high chance of compatibility issues and errors. In case you order the wrong components or parts, you won't have any idea about the problem until you face it in prototyping. Turnkey PCB manufacturers thus can help with this problem as it has a direct and stable relationship with the manufacturers and all the team guarantees to make a quality product with no errors.

Usually, time is required for rearranging and managing the product from one facility to another. Thus, services need to gather for a strong turnaround.

Cost saving is one of the major advantages of turnkey PCB assembly. The assemblies provide various ways of reducing the cost of manufacturing. It doesn't take the extra cost of delivering the components to the assembly house. They have a direct relationship with manufacturers. Thus, there is a signification reduction in the cost of components. You can achieve a good quality board without having any trouble. It is possible to reduce manufacturing costs by using turnkey PCB assembly companies that can prepare the PCB with all its components.

The more people the more the problem with communication and compatibility. Using multiple services for PCB assembly results in communication problems because of time and language barriers. This will cause a problem with the product.

Thus, with turnkey PCB assembly, the team can go through various steps and processes in a well-established manner. They know how to work with various departments and what is required to share for this process.

Although the turnkey PCB assembly is good in many factors, it also has some practical problems. Sometimes you choose to use the small turn-time PCB manufacturer, you may end up with low-quality products. This could also result in a lack of financial support for component management services. Sometimes operational problems can also affect the project. Some of them include legal trouble, rogue employees, and natural disaster issues.

Turnkey PCB assemblies have two types: partial and full.

A partial turnkey service involves outsourcing only part of an assembly process, which is a form of consignment manufacturing. Part of the supply chain is under the responsibility of the technology developer in a partial turnkey project. Assemblers receive materials from the tech developer, which are sorted and packaged before delivery.

Partially, turnkey services can save businesses money and speed up the manufacturing process when they already have most of the necessary parts on hand. The partial option is the best choice in case you have the parts and components and want to save money and time. Full turnkey service is more appropriate if you don't have components, aren't sure how to order them, or aren't sure what components suit your circuit board design.

They analyze your assembly service provider and provide you with the complete circuit board. They also source all the circuits and parts. But you need to provide them with the BoM(Bill of Materials), Product dimensions, Gerber files, and information regarding packaging and shipping.

In turnkey PCB manufacturers, sophisticated software platforms allow prototyping and small quantity orders to be integrated into larger ones in a cost-effective and timely manner. Uploaded design BoM and documents can receive an instant quote through an online portal; prototype delivery can happen in less time.

Traditionally, the quantity was a factor when determining cost in the production and manufacturing stage of the design process, but now, companies that accept Gerber files can provide a reasonable quote regardless of order size.

Customers can now calculate the cost per PCB manufactured through online pricing tools offered by electronic assembly providers. It is also possible for designers to track and report on the process of assembling circuit boards.

The turnkey PCB manufacturing approach uses the service provider for both device manufacturing and PCB assembly. All the process takes place in the same place and this reduces the risk of mishaps and shipping delays. The team can manage all of the production processes while on the other hand, the communication issue also gets solved or crossed out.

With the completion of PCB assembly, the PCB manufacturing partner can rent and manage space and inventory before shipping your product.

System integration is the last stage of the PCB assembly process. When a PCB manufacturer knows if an order has been placed, they can satisfy customers' needs. The software of PCB manufacturers integrates ERP systems via APIs, as in banking systems.

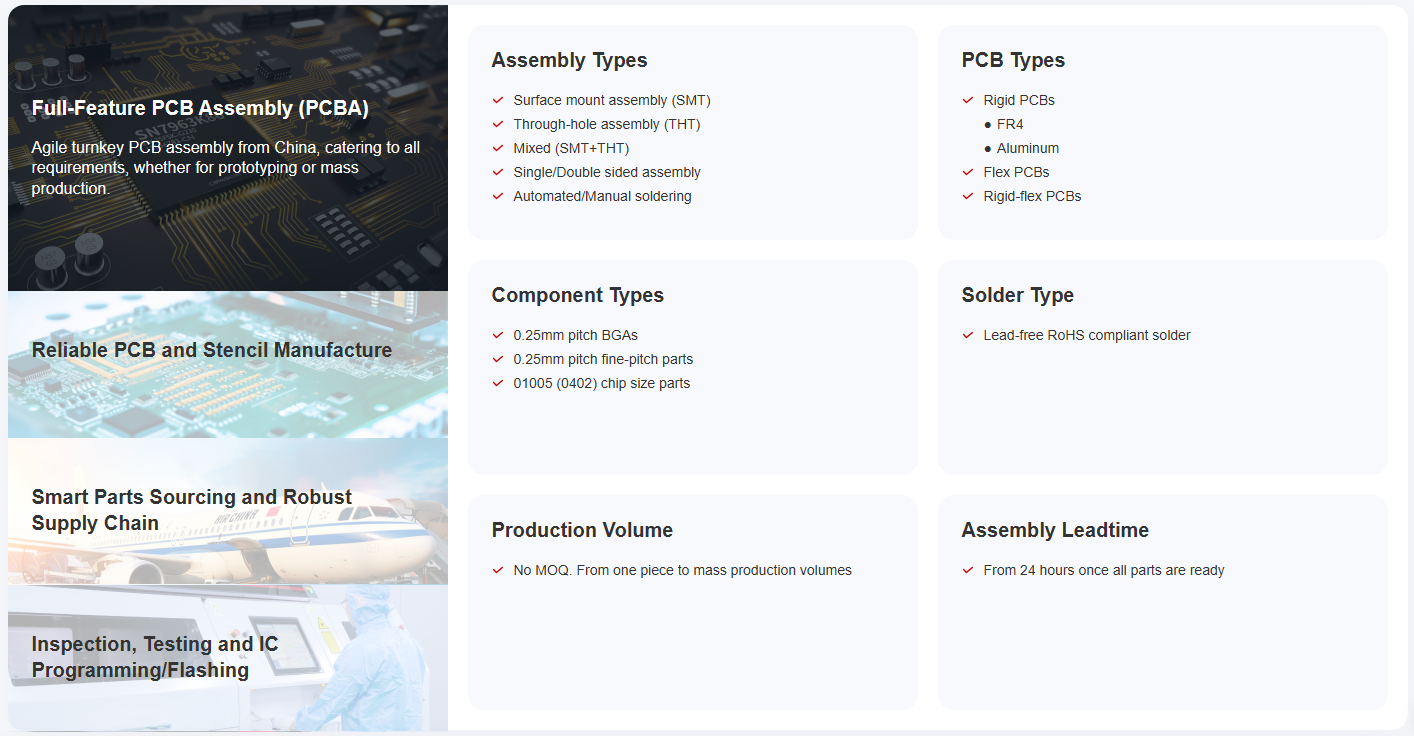

NextPCB's Capabilities of Turnkey PCB Assembly

With this method of turnkey PCB assembly, you can achieve both THT and SMT components in the circuit board. It has a wide range of applications and some of its areas include:

Quality: There is no any way to compromise the quality of the product. Thus, make sure the designer has the proper communication with the manufacturer. Make sure they use the best quality components and the circuit board.

Service: Confirm the types of services that they offer.

Cost: A designer can always reach out to multiple vendors for a better price offer. By doing so, you'd be able to get a sense of the cost per printed circuit board.

Speed: Make sure to confirm the delivery time of the product without compromising the quality of the product.

The selection of using turnkey PCB assembly is a wise choice and it is beneficial for both customers and end users. Below are some of the reasons you should choose this assembly process:

Consumer Electronics: In consumer electronics, such as smartphones, tablets, wearables, and home appliances, the demand for compact, high-performance, and cost-effective PCB assemblies is high. Turnkey PCB assembly services provide a single point of contact for sourcing components, assembling, testing, and delivering the final product. Manufacturers benefit from reduced lead times and lower costs due to streamlined operations.

Industrial Electronics: Turnkey PCB assembly plays a critical role in industrial control systems, automation equipment, and robotics. The process often involves custom designs, specialized components, and rigorous testing to meet the demanding conditions in industrial environments.

Medical Electronics: In the medical device sector, where precision and reliability are paramount, turnkey PCB assembly is essential for ensuring high-quality products. Medical devices such as diagnostic equipment, monitoring systems, and therapeutic devices often require complex circuit boards with stringent regulatory requirements. A turnkey service can help ensure compliance with medical industry standards and certifications such as ISO 13485 and FDA regulations.

Wearable Health Devices: With the rise of wearable health monitors, fitness trackers, and smart medical devices, turnkey PCB assembly offers an efficient solution for integrating sensors, processors, and communication modules into compact, high-performance circuit boards.

Automotive Electronics: Turnkey PCB assembly is increasingly critical in the automotive industry, particularly with the shift towards electric vehicles (EVs), autonomous driving systems, and advanced infotainment. PCBs used in these systems need to be highly reliable, robust, and capable of withstanding harsh environmental conditions (e.g., temperature fluctuations, vibration). Turnkey PCB services help streamline the sourcing and assembly of components like sensors, controllers, power management systems, and communication units.

Telematics & Infotainment: The demand for smart, connected vehicles is growing, making PCBs essential for telematics systems, navigation, and entertainment modules. Turnkey PCB assembly ensures that all necessary components are integrated correctly and tested for optimal performance.

Aerospace Systems: The aerospace industry relies on PCBs for a wide range of applications, from communication systems to flight control systems and avionics. These PCBs require high reliability and precision, as well as adherence to stringent safety standards. Turnkey PCB assembly ensures that all components meet the critical tolerances required for the demanding aerospace environment.

Defense Electronics: In defense applications, such as radar systems, communication devices, and weapon control systems, turnkey PCB assembly helps in meeting the rigorous standards for durability, functionality, and security. The integration of specialized components and components testing is essential to the safety and performance of these systems.

Telecom Equipment: PCB assemblies are essential in a wide range of telecommunications equipment, including routers, servers, base stations, and data processing units. Turnkey PCB assembly services are ideal for this sector because they can integrate complex systems involving high-speed data transmission, power management, and signal processing. The service ensures that all components work together efficiently and meet regulatory and performance standards.

5G and IoT Devices: As 5G technology and the Internet of Things (IoT) continue to grow, the demand for high-frequency, high-performance PCBs also increases. Turnkey PCB assembly supports the development of next-generation wireless communication devices, ensuring that all components are correctly integrated and tested for optimal performance.

Renewable Energy Systems: Turnkey PCB assembly plays a key role in the development of renewable energy products, such as solar inverters, wind turbine controllers, and energy storage systems. The integration of power electronics, sensors, and controllers on high-performance PCBs is critical to the efficiency and reliability of these systems.

Battery Management Systems (BMS): As electric vehicles and renewable energy storage solutions become more widespread, BMS systems are essential for monitoring and managing battery performance. Turnkey PCB assembly helps in the design and assembly of high-quality, reliable PCBs for these critical applications.

Smart Devices: The IoT revolution depends on reliable, compact, and energy-efficient PCBs. Devices like smart thermostats, connected home appliances, and wearable tech rely heavily on advanced PCB designs that can support sensors, wireless communication, and low-power operation. Turnkey PCB assembly services allow quick and efficient production, integrating the necessary components to ensure the device’s functionality.

Smart Cities and Industrial IoT (IIoT): In smart city infrastructure and IIoT applications, PCBs are used in sensors, controllers, and gateways to monitor and optimize urban systems like traffic, waste management, and energy use. Turnkey PCB assembly ensures that complex IoT devices are produced quickly and to specification.

Thus, turnkey PCB assembly is the future of electronic services since it has huge advantages. However, reliable and trustworthy partners are required with a good lead time for making the process seamless and cost-effective. It allows the manufacturer to make the best PCBs in very little time. All of the turnkey PCB assembly provides faster delivery.

NextPCB is one of the best turnkey PCB assembly-providing services. We provide you with the best quality services that follow international standards. You can contact us for all the assembly and manufacturing needs.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now