Support Team

Feedback:

support@nextpcb.com

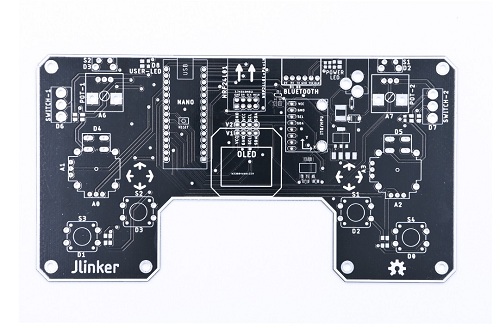

The silkscreen layer is the leading layer of the PCB well as functions as a recommendation sign for positioning elements on the PCB. The graphics and also message on PCB a circuit card is normally published with an irreversible non-conductive epoxy ink. The shade is commonly white, although various other shades are likewise readily available.

Display printing is utilized to define helpful info on the PCB board, which can assist individuals throughout the setting up. It is utilized to note part worths, component numbers, examination factors, polarity, and so on

. The issues connected to the product of silkscreen are seldom taken place, other than possibly some staining after high PCB reflow temperature levels for RoHS certified soldering. Silkscreen issues are constantly triggered by the layout of the PCB. So the adhering to a component will certainly take a while to point out a couple of standards of the silkscreen style.

If silkscreen epoxy is published over lands PCB or pads that will certainly be soldered, it will certainly merge the solder joint throughout reflow as well as deteriorate the add-on. For that reason, silkscreen ought to constantly be published in addition to the mask product and also never ever over-solderable surface areas. Several CAD systems can clip the silkscreen far from subjected steel, yet when producing collection elements make sure to maintain the part details and also polarity marks far from the pins (0.25 mm) by default, as well as listen when relocating or revolving referral designators or when including a message to PCB the last board layout.

The size of silkscreen graphics can likewise be an issue. If as well slim, we will certainly have troubles in the testing or printing process as well as skips can take place. If as well thick, the message might be also blurred to check out. As parts obtain smaller sized in dimension, as well as circuit thickness, remains to raise, it is occasionally really tough to publish silkscreen in all, however, attempt to make use of line sizes not less than 0.15 mm (6 mils), 0.18 mm to 0.20 mm is favored PCB.

Solder pads ought to never ever be overprinted, since this might result in issues throughout soldering, setting up, and also with the E-Test. If we must identify an overprinted solder pad (spacing < 150μm) after that Multi-CB gets the right to get rid of the noting print at this area. Appropriate for the interpretation of the solder pads is the solder pad exception. The noting print is typically instantly clipped with a spacing of 100μm to the solder-stop side.

The spacing in between solder pads as well as noting print needs to go to the very least 150μm. Constantly prevent overprinting solder pads!

It is a printing technique utilizing a plate product with chemical fibers in a mesh kind. By scrubbing ink with a squeegee, ink is pushed out in between the meshes and also published on the board. For silk printing of published motherboards, it is a basic building and construction technique.

This is a printing approach that takes in ink by straight splashing onto a substratum. This is an eco-friendly approach due to the fact that no sheets or movies are utilized. The print resolution is more than "display printing". Inkjet white inks might have a somewhat milklike "milklike" look.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|

Inell

PCB screen printing is used in many double-sided and life-threatening printed boards. Solder resist film is the application of PCB screen printing technology on double-sided and multilayer printed boards.