Introduction: The Invisible Language of Quality: Why IPC Standards are Non-Negotiable?

A printed circuit board, or PCB, serves as the nervous system of any electronic device, from a common smartphone to a cutting-edge medical implant. Just as a single faulty synapse can disrupt the entire human nervous system, a single defective solder joint can cripple an electronic assembly, potentially disabling an entire platform in high-stakes applications like defense systems. In the world of electronics manufacturing, where the tiniest defect can have catastrophic consequences, quality is not a luxury; it is a fundamental requirement.

This is where IPC standards come in, acting as the indispensable blueprint for excellence.

The IPC, or the Association Connecting Electronics Industries, is the global body that provides a common language and a "quality bible" for the electronics industry. These standards ensure the consistency, reliability, and durability of electronic products, serving as a benchmark for excellence across the entire supply chain. Their influence is so profound that compliance is often essential for companies seeking to expand their market presence globally.

At their core, IPC standards are more than just a set of technical rules; they are a communication protocol. This shared, standardized language eliminates confusion between designers, manufacturers, and inspectors, dramatically speeding up verification and preventing costly errors and rework. For a contract manufacturer, being able to communicate with customers and suppliers in this universal language is critical. When a manufacturer certifies a product as "acceptable," that designation is not a relative concept based on internal, proprietary metrics. Instead, it means the product meets standards that are universally recognized and accepted by the industry at large.

Soldering is Not Just Soldering!

A common misconception is that "soldering is just soldering" and that a company's internal workmanship standards are sufficient. This perspective, however, overlooks a critical point. Without a universally accepted standard like IPC, a company's definition of a "good" product is meaningless outside its own walls. This can lead to a breakdown in communication and trust across the supply chain, as what one party deems a "pass" might be a "fail" to another. The IPC framework provides an objective and robust metric, transforming a subjective opinion into a quantifiable and verifiable benchmark.

For readers seeking a practical example of how these standards are applied in real-world manufacturing, NextPCB’s PCB assembly capabilities demonstrate end-to-end solutions that comply with IPC requirements, ensuring consistent quality and reliability.By adhering to these standards, manufacturers can improve production efficiency, minimize defects, and ultimately enhance market competitiveness and trust.

It is important to note that the term "IPC" is an acronym used in other fields, such as medicine, where it stands for "Infection Prevention and Control". This is a completely different domain and has no relevance to the standards for electronics manufacturing. The information presented here in this blog pertains exclusively to the IPC that serves the electronics industry.

Table of Contents

- 1. The Dynamic Duo: IPC-J-STD-001 vs. IPC-A-610 Explained

- 2. Class Act: Understanding the Three Tiers of Electronics

- 3. The 2024 Update: Diving into the 'J' Revisions

- 4. The ROI of Quality: From Compliance to Competitive Advantage

- 5. The Path Forward: Partnering with an IPC-Certified Professional

Get IPC-Compliant PCB Assembly Services

The Dynamic Duo: IPC-J-STD-001 vs. IPC-A-610 Explained

The world of IPC standards can initially seem complex, but two core documents for soldering and assembly form a powerful, symbiotic relationship. These are IPC-J-STD-001 and IPC-A-610. A simple analogy helps to clarify their distinct yet interconnected roles: imagine that IPC-J-STD-001 is the recipe, and IPC-A-610 is the final inspection.

IPC-J-STD-001J: The Process Standard (The Recipe)

This standard, formally titled Requirements for Soldered Electrical and Electronic Assemblies, defines the process and materials used to create a high-quality soldered product. It is the guidebook for the fabrication process itself. It sets stringent requirements for:

- Materials: It specifies which solders, fluxes, and cleaning agents can be used, with specific requirements for their composition. For example, it provides guidelines for materials like tin-silver-copper (SAC) alloys and bismuth-containing alloys for low-temperature applications.

- Methods: It outlines the proper techniques for soldering, including preheating parameters, peak temperature control, and time above liquidus specifications.

- Manufacturing Environment: It details the environmental controls necessary for quality production, such as maintaining temperature and humidity levels within specified ranges (18−30∘C and 30−70%RH) and implementing appropriate ESD protection measures.

Adherence to IPC-J-STD-001 is about ensuring consistency and control during the assembly process. It is the "supply side" of quality, focusing on the procedures that build a robust and reliable assembly.

> Recommend reading: Circuit Board Solder: Types, Temperatures & How to Choose (Reflow & Hand Soldering Tips)

IPC-A-610J: The Acceptability Standard (The Final Inspection)

This document, formally known as Acceptability of Electronic Assemblies, is the industry benchmark for visual inspection of a finished product. It does not define how to solder; instead, it provides detailed visual criteria and images to determine what constitutes an acceptable solder joint and a defect. It is used for final inspection, ensuring that the completed assembly meets the necessary quality benchmarks for its intended application. This is the "demand side" of quality, providing the rigorous inspection criteria to ensure no defects are shipped to customers.

Understanding IPC Standards for Soldered Assemblies

The profound power of this partnership lies in their synergy. IPC-J-STD-001 and IPC-A-610 are designed to be used together. The rigorous process outlined in J-STD-001 is the most effective way to produce an assembly that will meet the visual acceptance criteria of A-610. The A-610 standard serves as the final arbiter, verifying that the J-STD-001 process was successfully executed. Using one without the other is a fundamental error: a perfect process that fails to meet the visual criteria is of no value, just as a product that looks perfect but was made with a flawed process will likely fail in the field.

An important principle found in both standards is that the text takes precedence over illustrations. This is not merely a formatting detail; it is a philosophical statement about quality assurance. It means that the visual examples in the standard are guides, not absolute rules. The true requirement is found in the written text, which necessitates a trained inspector's judgment and deep understanding of the standard's nuances. This highlights the vital importance of certified personnel, who possess the expertise to interpret the standard's core principles rather than relying solely on visual matching.

The latest revisions of both standards, IPC-J-STD-001J and IPC-A-610J, were released in March 2024. While some older sources might still refer to the "H" revision as the latest, the "J" versions are the current, globally accepted documents. The letter "I" was intentionally skipped in the revision sequence to avoid confusion with the number one (1) or the lowercase letter L, a detail that demonstrates the meticulous nature of the standards-setting body.

The following table provides a quick-reference guide to these two foundational documents, simplifying their complex relationship.

|

Standard |

Full Name |

Core Function |

Primary User |

Analogy |

|

IPC-J-STD-001J |

Requirements for Soldered Electrical and Electronic Assemblies |

Defines the soldering processes and materials. |

Engineers & Operators |

The Recipe |

|

IPC-A-610J |

Acceptability of Electronic Assemblies |

Defines the visual acceptance criteria for the final product. |

Inspectors & QA |

The Final Inspection |

Class Act: Understanding the Three Tiers of Electronics

The IPC standards do not apply a single, one-size-fits-all rule to every electronic product. Instead, they classify products into three tiers, or "classes," based on their intended use, reliability needs, and operational environment. This tiered system allows manufacturers and customers to match the product's quality level to its function, balancing performance with cost.

The three classes represent a cascading hierarchy of acceptability. A defect for Class 1 automatically implies a defect for Class 2 and 3, and a defect for Class 2 implies a defect for Class 3. This means that the requirements for Class 3 are the most stringent, encompassing and exceeding the requirements of the lower classes.

Class 1: General Electronic Products

Class 1 is for general-use consumer products where the primary goal is short-term functionality. These products are often disposable or have a relatively short lifespan, and a certain extent of cosmetic imperfection is acceptable as long as it does not affect functionality. The least stringent of the three classes, Class 1 products include everyday items such as toys, flashlights, and remote controls.

Class 2: Dedicated Service Electronic Products

Class 2 is the most common classification for electronic assemblies. It applies to products where extended life and uninterrupted service are desired, but not mission-critical. This class is more rigorous than Class 1 and sets a higher standard for quality and performance. It is the standard for a wide range of consumer electronics, including smartphones, laptops, televisions, and industrial equipment.

Class 3: High-Performance Electronic Products

This is the highest level of performance and quality, reserved for products where failure is simply not an option and could have severe consequences. Assemblies in this class are designed to operate without failure for extended periods, often in harsh or extreme conditions. Class 3 is the standard for mission-critical applications in industries such as aerospace, military equipment, and medical devices where reliability is paramount.

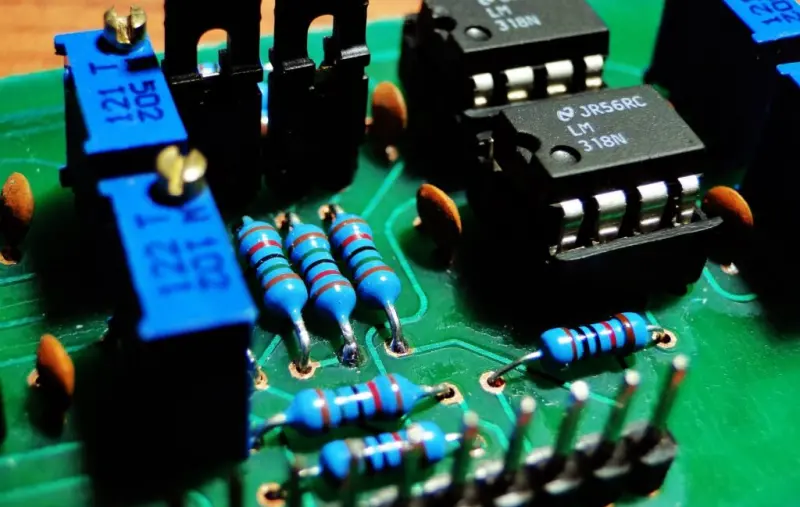

The differences between these classes are not abstract; they are defined by specific, quantifiable criteria. A key distinction lies in the requirements for solder joint quality, which become progressively tighter with each class. The following table illustrates these differences with specific, data-backed examples.

|

Class |

Description |

Reliability Need |

Example Products |

Solder Joint Criteria |

|

Class 1 |

General Electronic Products |

Short life, basic functionality |

Toys, flashlights |

Least stringent requirements, some imperfection allowed. |

|

Class 2 |

Dedicated Service Products |

Extended life, desired functionality |

Smartphones, laptops, microwaves |

End Joint Width: min 50% of lead width. Side Overhang: max 50% of lead width. Through-Hole Barrel Fill: min 50%. |

|

Class 3 |

High-Performance Products |

Uninterrupted service is mission-critical |

Medical devices, aerospace systems, military equipment |

End Joint Width: min 75% of lead width. Side Overhang: max 25% of lead width. Through-Hole Barrel Fill: 100% where possible. |

Choosing the correct IPC class is a strategic business decision that balances a product's intended function with manufacturing cost and market competitiveness. While it may be tempting to default to Class 3, designing for Class 2 often provides an optimal balance of cost and reliability for a wide range of commercial products. Conversely, for life-critical devices, Class 3 is the only acceptable standard.

>Recommend reading: IPC Class 2 vs 3: The Differences in PCB IPC Standards

The 2024 Update: Diving into the 'J' Revisions

IPC standards are not static documents; they are dynamic, living specifications that evolve to keep pace with the rapidly changing landscape of the electronics industry. Updated regularly by a global committee of subject matter experts from dozens of countries, these revisions are a direct response to new technologies, materials, and feedback from the manufacturing community. The latest versions of both standards, IPC-J-STD-001J and IPC-A-610J, released in March 2024, represent a significant evolution in quality requirements.

Key Updates in IPC-J-STD-001J

The "J" revision of IPC-J-STD-001, developed over three and a half years by a global team of experts from 27 countries, incorporates a wide range of input to improve clarity, consistency, and practical application. Notable changes include:

- Centralized Electrical Clearance: Previously scattered electrical clearance requirements have been thoroughly reviewed and consolidated into a single, centralized section. This change streamlines the application of the standard, making it easier for users to locate and interpret critical information and eliminating the inconsistent references that appeared in previous versions.

- New Terminology: The standard introduces new definitions such as "bubble" and "bridging bubble" to provide more precise descriptive language for potential solder defects. This improves communication and reduces confusion when describing anomalies.

- Nickel Contamination: Based on new data and testing results, the allowable level of nickel (Ni) contamination in solder baths has been increased, reflecting a more pragmatic approach to a common manufacturing challenge.

- Centralized Termination Guidance: Guidance for center and lateral terminations has been placed into a new, centralized section. This improves the organization of the standard, making it more intuitive for assembly operators and inspectors.

Key Updates in IPC-A-610J

> Read full guide of IPC-A-610 Standard: Ultimate Guide to Electronic Assembly Acceptability

The latest revision of IPC-A-610, the visual inspection standard, was updated to address the increasing complexity of modern electronic assemblies and emerging manufacturing challenges. Key changes from the previous "H" revision include:

- Improved Visual Guidance: The document has been substantially enhanced with new images to improve visual inspection guidance, making it easier for inspectors to identify acceptable and unacceptable conditions.

- Conformal Coating: New guidelines have been added for conformal coating inspection, with specific clarification on how to assess voids and bubbles.

- Updated Cleanliness & Soldering: The "J" revision includes improved guidelines for solder joint evaluation and updated cleanliness standards to address the challenges of modern flux residues.

- The Removal of "Target Condition": An important philosophical change was made in the previous "H" revision with the removal of the "target condition" throughout the document. This shift reflects a move from a perfection-based, "ideal" standard to a more pragmatic set of criteria focused on achieving a reliable, high-quality, and acceptable outcome.

The evolution of these standards proves that the IPC is a living, responsive organization. The updates are a direct, pragmatic response to real-world problems. The changes to things like nickel contamination and conformal coating bubbles demonstrate the committee's commitment to adapting to new materials and processes that are now common in manufacturing. Staying current with these latest revisions is therefore essential for any manufacturer aiming to stay ahead of the curve.

The ROI of Quality: From Compliance to Competitive Advantage

For many, adhering to IPC standards may seem like a burdensome cost or an exhaustive checklist. However, from an expert's perspective, compliance is not a cost; it is a strategic investment that yields significant, tangible returns. This commitment to standardized quality transforms a manufacturer's operations from reactive to proactive, leading to substantial financial and reputational benefits.

The Financial Case

Adherence to IPC standards directly impacts a manufacturer's bottom line by reducing costs and waste.

- Reduced Rework and Scrap: By following a standardized, controlled process, manufacturers can significantly reduce workmanship errors and defects from the outset. Fewer defects lead to a lower scrap rate and minimize the need for labor-intensive rework cycles, which directly improves a manufacturer's profitability.

- Minimized Warranty Claims: A high-quality product is, by its very nature, more reliable. Ensuring quality from the assembly phase helps to prevent component failures and costly product returns under warranty, saving a manufacturer from financial losses and logistical headaches.

The Reputation and Market Case

In addition to financial benefits, IPC compliance is a powerful tool for building a trusted brand and expanding market reach.

- Building a Trusted Brand: Compliance with globally recognized standards signals a manufacturer's unwavering commitment to quality. This builds confidence in a brand, strengthens customer loyalty, and ultimately contributes to long-term business growth.

- Accessing High-Value Markets: Many high-value industries, such as aerospace, medical devices, and defense, mandate compliance with IPC standards, particularly the rigorous Class 3 requirements. By achieving and maintaining certification, a manufacturer can open doors to these lucrative, specialized markets, gaining a competitive edge.

- Streamlined Communication: In a globalized supply chain, a common industry standard facilitates consistent expectations and smooth collaboration between manufacturers, suppliers, and customers. IPC standards act as a universal quality "passport," which promotes smoother cross-border transactions and makes a manufacturer a more reliable and competitive partner in the global marketplace.

Ready to gain a competitive edge in a crowded market?

> Discover how our commitment to the latest IPC standards can elevate your product’s quality.

The Path Forward: Partnering with an IPC-Certified Professional

The world of electronics manufacturing is a complex landscape where the smallest detail can make a monumental difference. Staying current with the latest IPC standards is not merely a formality; it is a fundamental requirement for ensuring product reliability, reducing costs, and building a competitive advantage.

Summary of Key Takeaways

- IPC standards are the universal language of quality in electronics manufacturing, providing a shared benchmark for excellence.

- IPC-J-STD-001 and IPC-A-610 are the indispensable "dynamic duo," defining the process and the final acceptance criteria, respectively.

- The three IPC classes (1, 2, and 3) allow for a strategic alignment of product quality with its intended use, from consumer electronics to mission-critical devices.

- The latest "J" revisions are not arbitrary; they are a living reflection of the industry's evolution, offering improved clarity, new technical guidance, and enhanced visual support.

- Compliance is an investment, not a cost, offering tangible benefits through reduced rework, minimized warranty claims, and a fortified market reputation.

> Recommend reading: PCB Manufacturing Basics: Design, Fabrication, Testing, and Compliance

For any business, from a new startup to a global enterprise, navigating this intricate landscape can be challenging. At NextPCB, our commitment to the latest IPC standards and certified personnel is your assurance of excellence. The difference between a product that simply works and one that is guaranteed to perform reliably is the difference a truly expert partner makes.

Contact us today to discuss your next high-reliability project.