Support Team

Feedback:

support@nextpcb.com

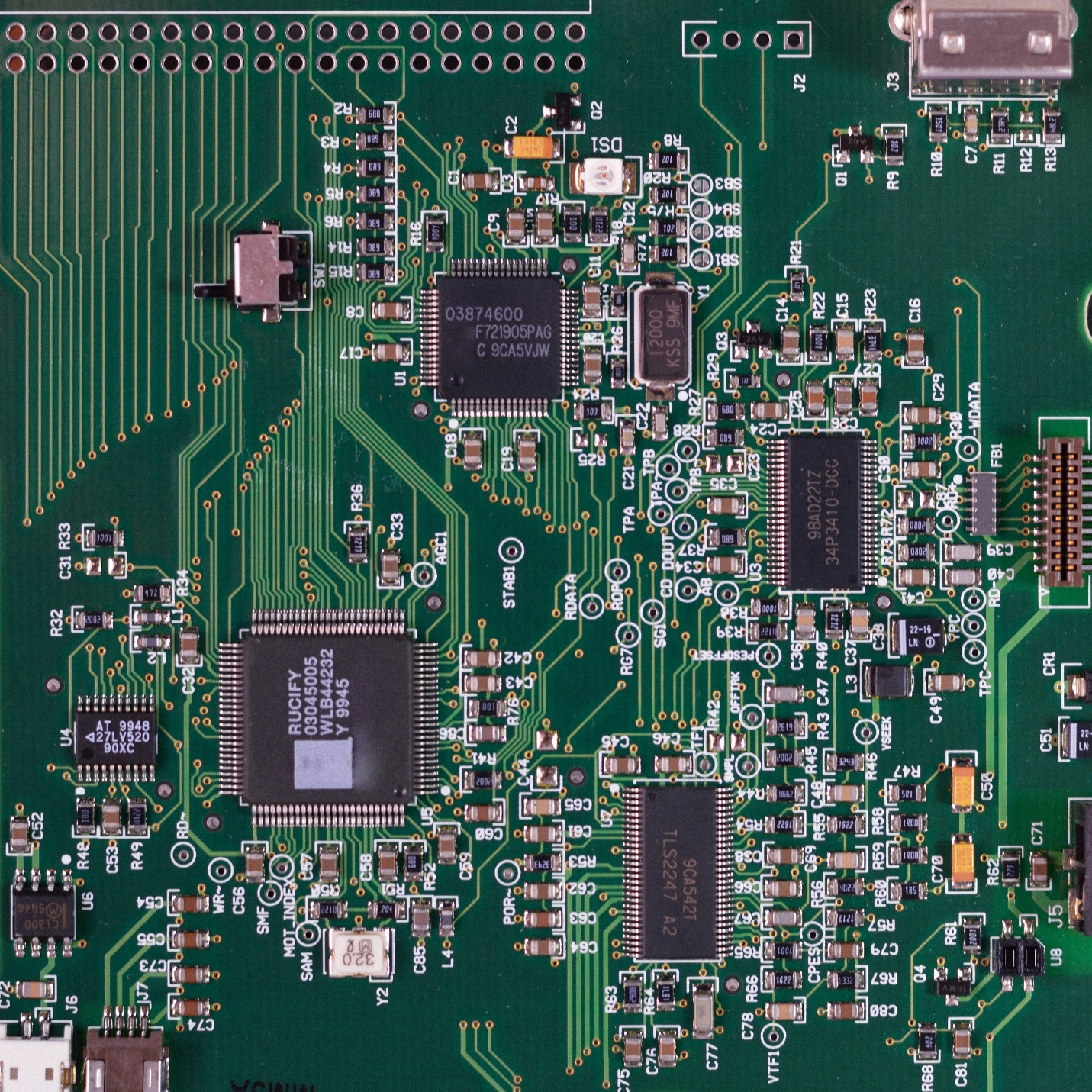

Green PCBs are everywhere. Modern Printed Circuit Boards often come in various colors; red, black, green, purple, pink, and yellow. However, many PCB manufacturers often use a particular color in their circuit board design, and that color is green.

It has become a common trend for PCB manufacturers and designers to use the color green. In fact, many consumers believe that all PCBs are green-colored, and it became a standard color because of the United States Military. Also, if consumers notice any variance in the color of their PCBs, it would mean that the electronic device has some defect.

Everyone needs to understand why most Printed Circuit Boards are green and how selecting the best color for your PCB can provide visual differences for your circuit boards. This guide provides excellent discussions into the world of Green PCBs. To begin, what is a Green Printed Circuit Board?

An important parameter in designing PCBs is the PCB solder mask color choice. This solder mask helps to protect the circuit board’s copper wires. Hence, the role of colored PCBs is to protect and help identify components on the circuit board with ease.

Green PCBs are circuit boards coated with a green solder mask or oil. This green solder mask is made from a glass known as epoxy. the application of epoxy on the circuit boards prevents a short circuit. Also, the material gives Green PCBs a reflective and shiny appearance which is aesthetically pleasing.

Another notable feature about green Printed Circuit Boards is that they are not green all the way through. While the solder mask provides a greenish appearance and protects copper traces from moisture and dust, typical circuit boards come in dull Yellow.

With the revolution of the PCB industry, many colors came into existence based on the needs of consumers and manufacturers. However, many PCBs come with green color for easy inspection of the circuit boards and their respective components.

There have been exciting theories about why green color precedes the choice of PCB colors. Many point to the United States Military’s role in PCB development in the 1950s. Some also believe that the color green made an impact through industrial design and revolution.

Whatever the reasons are, green PCBs will continue to show their purpose well into the future of PCBs. This guide provides several reasons why Most PCBs in electronic devices are usually lacquered green.

During the early development of Printed Circuit Boards, PCB designers and workers checked the circuit boards with their bare eyes. During PCB inspections, they squint their eyes all day to inspect the tiny components for faults which can be exhausting.

Despite the early setbacks, medical experts opined that the green color positively relaxes the body. green also helps reduce physical and visual fatigue. In addition, scientists examining the human eyes found that eye sensors called cones are sensitive to green light than other colors of the visible light spectrum. This expert opinion is visible. When humans take a walk in the park or open fields, they feel relaxed and energized.

In addition, the green color provides greater contrasts between the copper traces, silkscreen printing, pads, and other spaces on the circuit board. As a result, during Automatic Optical Inspection (AOI) on circuit boards, green PCBs effectively identify defects in components of the circuit board.

During the 1950s, the United States military diligently studied Printed Circuit board development and the choice of color in their machines and devices. After strenuous tests, the Army discovered that green was a practical color for PCBs.

As a result of their extensive PCB tests, green PCBs became a norm in the PCB industry and served their purpose in non-military applications. Also, businesses did not need to change the color of PCBs as only manufacturers and designers saw these circuit boards during the manufacturing stages.

An excellent material used in making green solder masks is glass epoxy. This material has a natural green tint and became a widely available material in designing Printed Circuit Boards. This availability of glass epoxy makes it cheaper, as any country or region has no monopoly on the material.

Also, while green PCBs do not make devices work differently, the green solder mask performs better at older mask dam than other colors available in the PCB market. For instance, green solder mask dams at 0.1mm while black and white dams at 0.15. Also, the primary colors (Red, Blue, and Yellow) dams at 0.12mm.

Many manufacturing plants can mass produce green PCBs, commonly used in devices and machines globally. The amount of Research and development made to ensure green solder masks are efficient makes it easy to mass-produce green PCBs. Also, it makes the production process of Printed PCBs less time-consuming and cheaper since they are not solder masks’ custom colors.

The truth is that when making a PCB, the choice of color does not affect the performance of the circuit board or the device it will power. However, the resolution of PCBs is affected. How so?

Green provides a better visual advantage in identifying components on the circuit boards. Many Integrated Circuits and motherboards are usually coded green, which helps designers and engineers to correctly identify components than any other color of the rainbow spectrum.

While many PCB manufacturers try to expand their color offerings, however they possess their strengths and weakness. Red and Blue PCBs offer improved visual inspections of the components. At the same time, Black PCBs often struggle with overheating issues, and white PCBs make it challenging to read and identify components on the circuit board.

To help manufacturers avoid issues with other PCB colors, they use the standard and popular color to manufacture PCBs: Green.

When picking the right PCB color for your needs, consider the following.

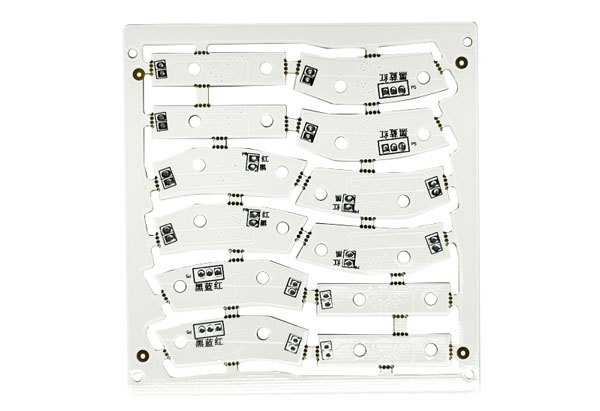

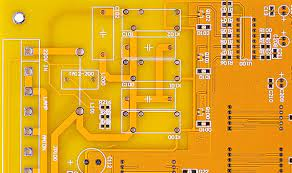

The choice of PCB color depends on your design specifications. While designers go with the “if it’s not broke, do not fix it” standard PCB color (green), many still venture to other PCB colors based on a design or consumers’ needs. Below is a simplified analysis of specific color PCBs you can choose from other than Green PCBs.

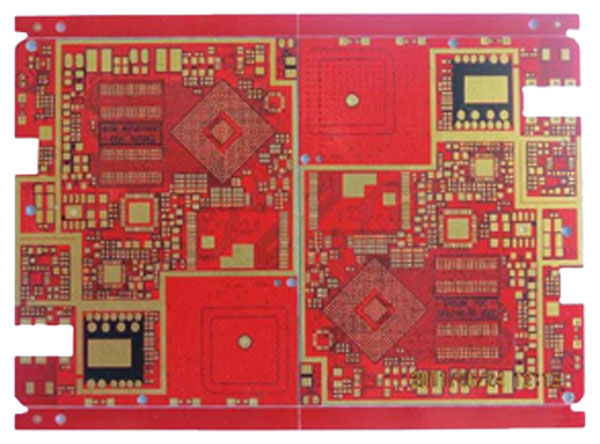

Red solder masks are often bold and offer excellent contrasts between the copper traces and spaces on the Circuit Board. As such, red PCBs are attractive and visually pleasing to the eyes. However, the contrast of red PCB is significantly lower than green PCB, which requires a degree of magnification during inspections.

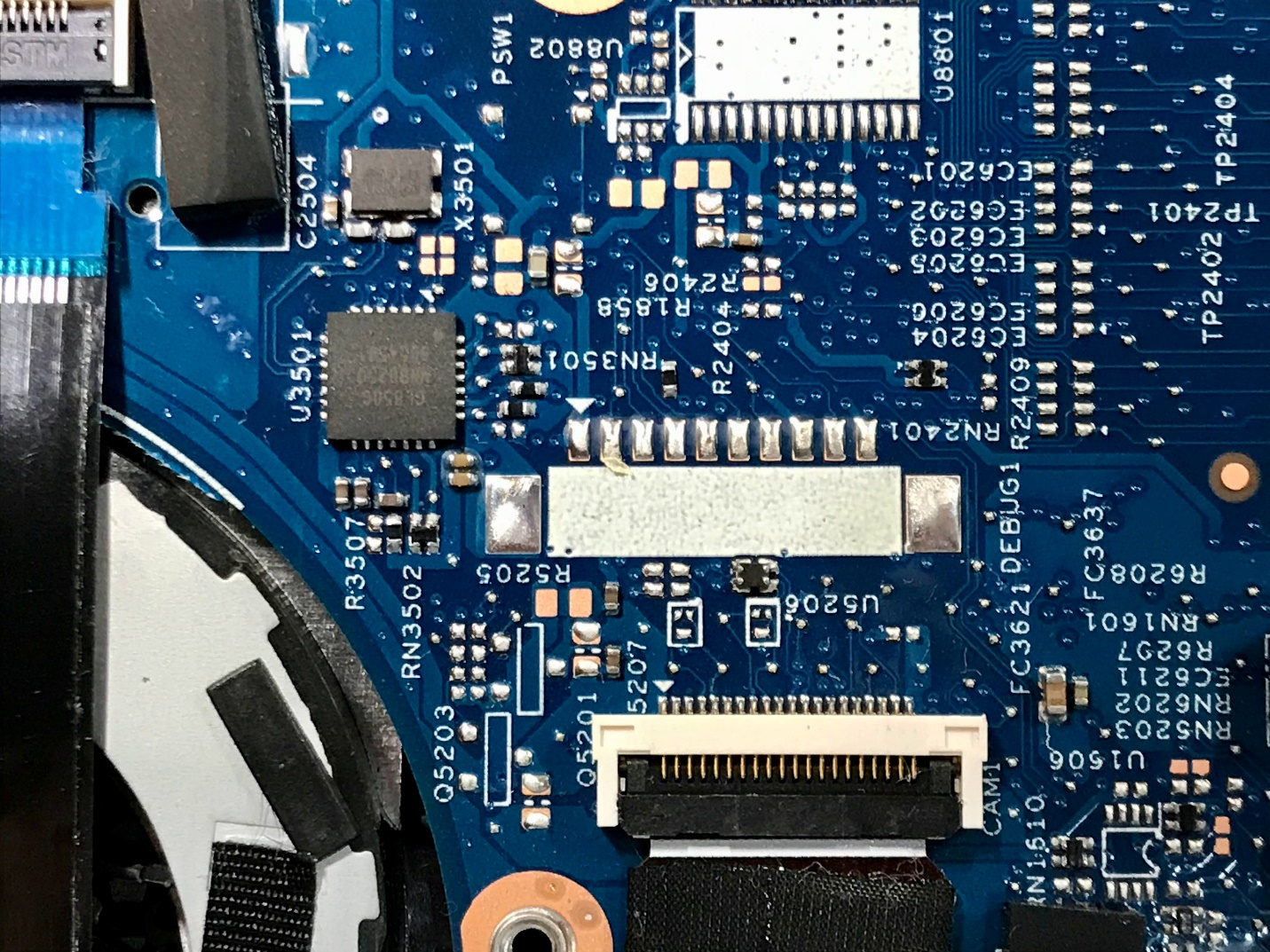

Blue PCBs share a resemblance with Arduino boards. While the contrast between the solder mask and silkscreen is on the high side, the contrast between empty spaces and traces is poor. As a result, magnification is necessary and compulsory for manufacturing defects inspection.

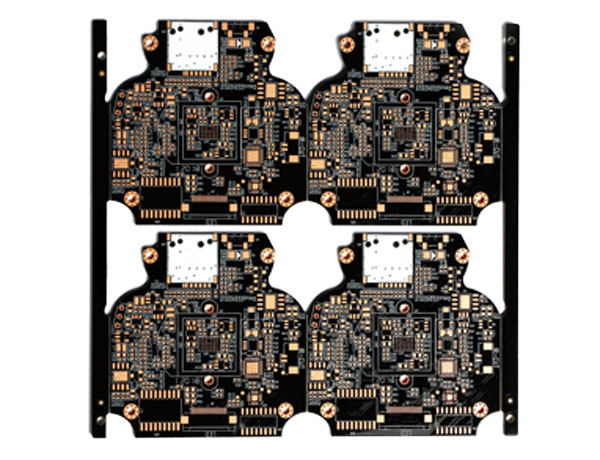

Black PCBs are considered prestigious as Tech Giants utilize the black solder mask on their printed circuit boards’ design. However, black PCBs struggle with heat absorption during the reflow process; it is harder to clean and difficult to inspect.

White PCBs are considered the worst nightmare of all colored PCBs. Research has shown that nothing good comes from a white solder mask. It offers the poorest of contrasts in that bending a white PCB is difficult to see and notice any defects when it comes to inspection. We strongly do not recommend the use of White PCBs.

Yellow solder mask is an excellent alternative to green PCBs. Compared to green, yellow solder masks offer high contrasts between their empty spaces and copper traces. As such, they are excellent to work with and offer improved visual inspection. However, it is surprising to realize that many PCB designers do not consider using Yellow in their PCB designs.

Your choice of PCB color does not improve the performance of the circuit board or the device it powers. However, choosing the right solder mask color for your PCB is essential since solder masks prevent copper traces on the circuit board from oxidizing. Also, the need for your coated copper traces to show up clearly is vital to avoid short-circuiting your PCB.

An excellent choice of solder mask color is green. It offers superior contrasts; it is widely available, has undergone major military and non-military tests, and has stood the test of time. As mentioned in the guide earlier, if the green PCB is not broken, there is no reason to replace it with another PCB color.

However, there are mentions of other colors PCBs can come in, so you must consider their comparative advantages and drawbacks to green PCBs. It will enable you to make the right decisions if you want to venture into the world of custom PCBs.

If you want to know more about PCB colors available or have PCB-related discussions, ensure you contact us on our official homepage, and we will provide you with the necessary information.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now