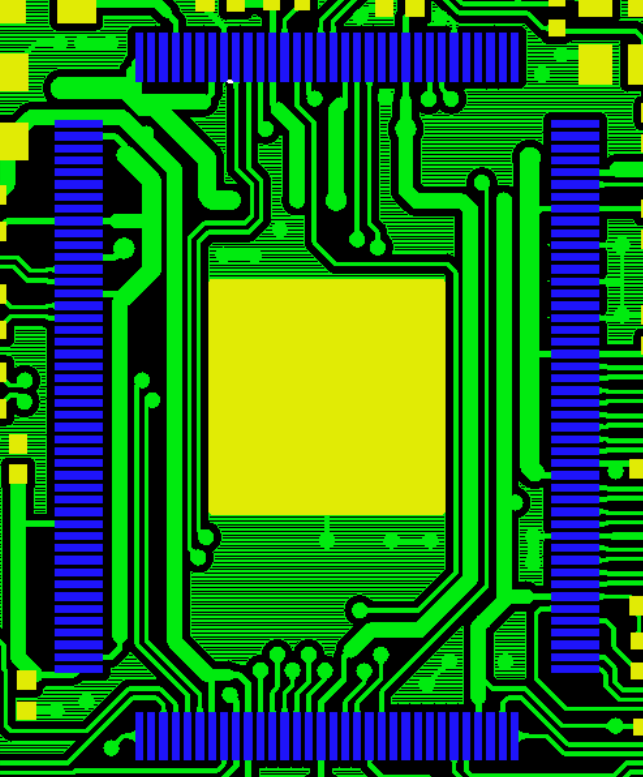

If the distance between the pads is too close, the solder resists bridge between the pads will not be retained, and it is easy to cause a short circuit during soldering. If the pad pitch is less than 8mil, an immersion gold process is required.

The design of the pad is too large, and the solder connection

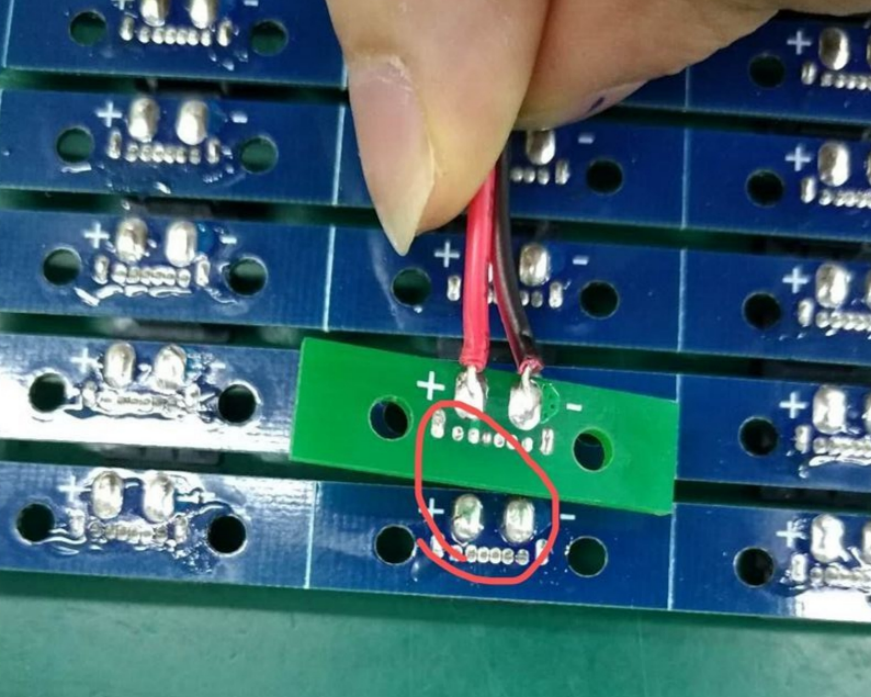

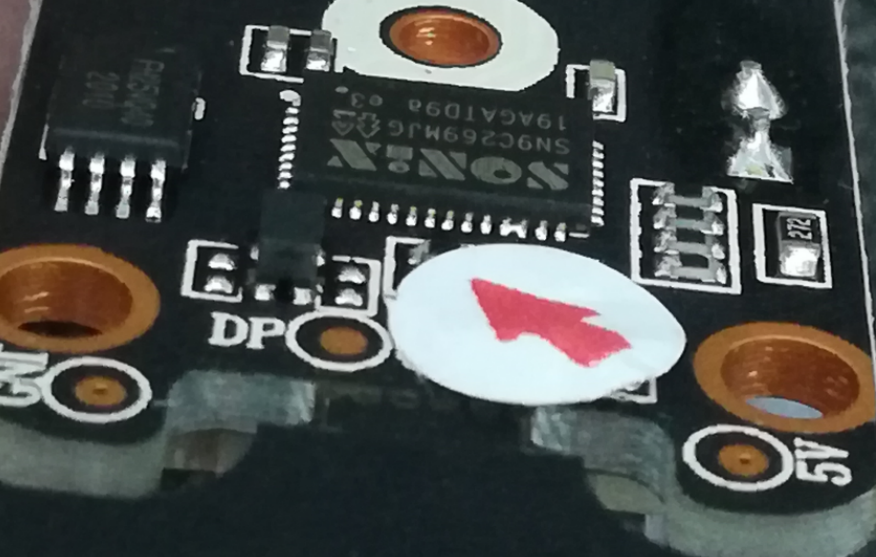

Too small spacing between pads can easily lead to soldering and tinning

Too small spacing between pads can easily lead to soldering and tinning

5.11mil pad pitch cannot retain solder mask bridge

In order to avoid the risk of short-circuit with tin during soldering, the spacing between the pads should be increased as much as possible in the design to preserve the solder mask.

The solder mask parameters of the corresponding colors are as follows:

Green oil: the pad spacing is greater than or equal to 7mil;

Black oil, white oil: the pad spacing is greater than or equal to 9mil;

Blue oil and others: The pad spacing is greater than or equal to 8mil.