Support Team

Feedback:

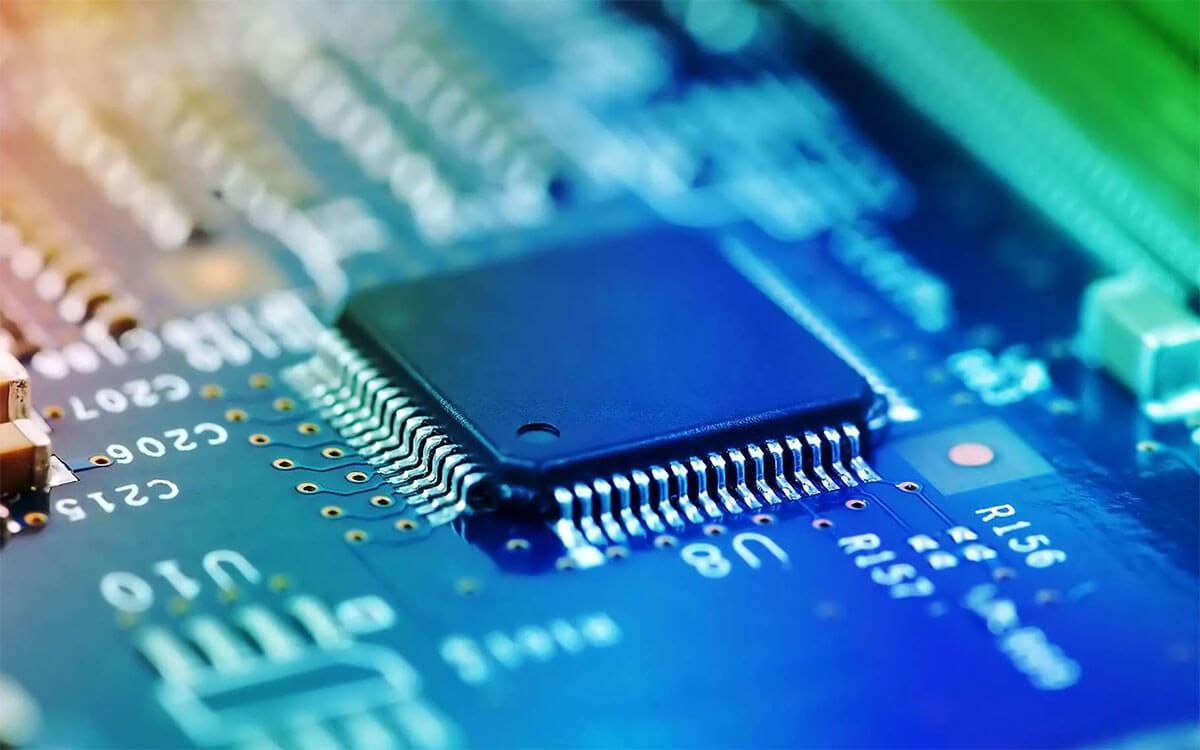

support@nextpcb.comCircuit board components are essential components in a wide range of electronic devices, from smartphones and laptops to cars and airplanes.

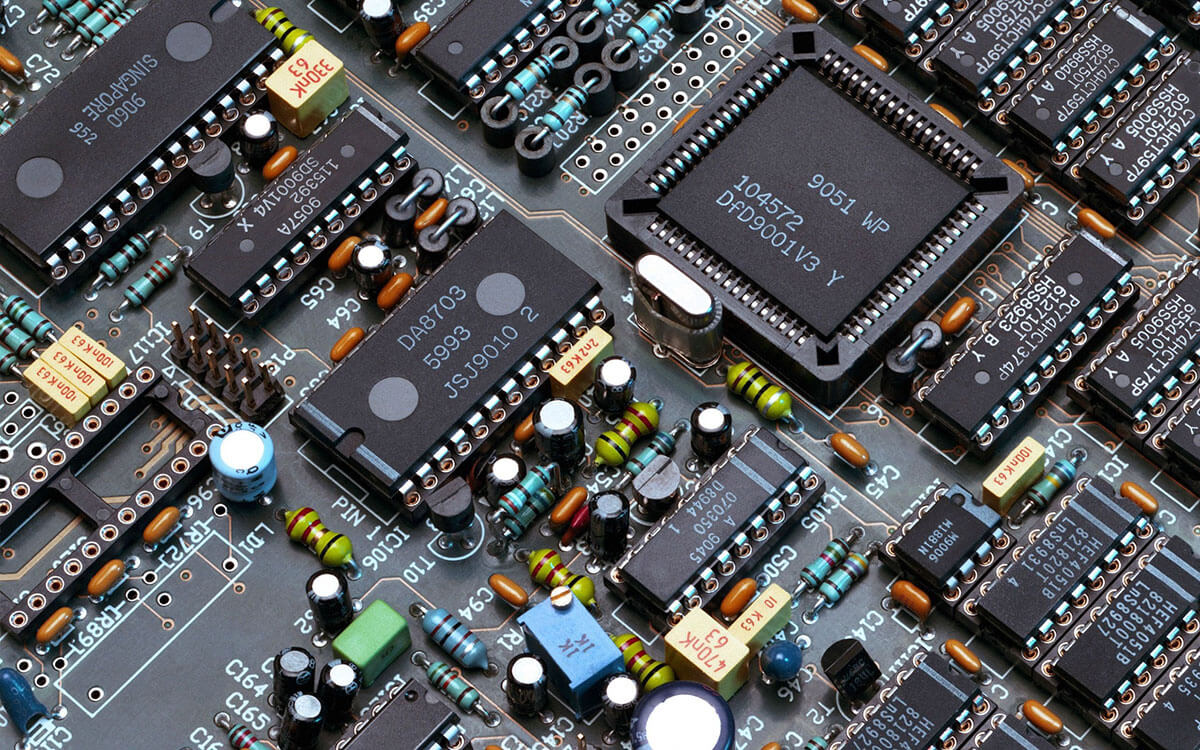

A circuit board is a board with small electronic parts, like resistors, capacitors, diodes, and transistors. It's also called a printed circuit board (PCB). Special paths connect these parts to conduct and control the flow of electricity in a device.

This article aims to give you a complete overview of circuit board parts, what they do, and why they matter in today's electronics. You will learn about the various types of parts used in circuit boards, how to select them, and the process of manufacturing and testing them for quality by the time you finish reading.

Small electronic pieces call circuit board parts to create electronic systems by placing them on a circuit board. There are three types of circuit board parts: basic parts, power parts, and mechanical parts.

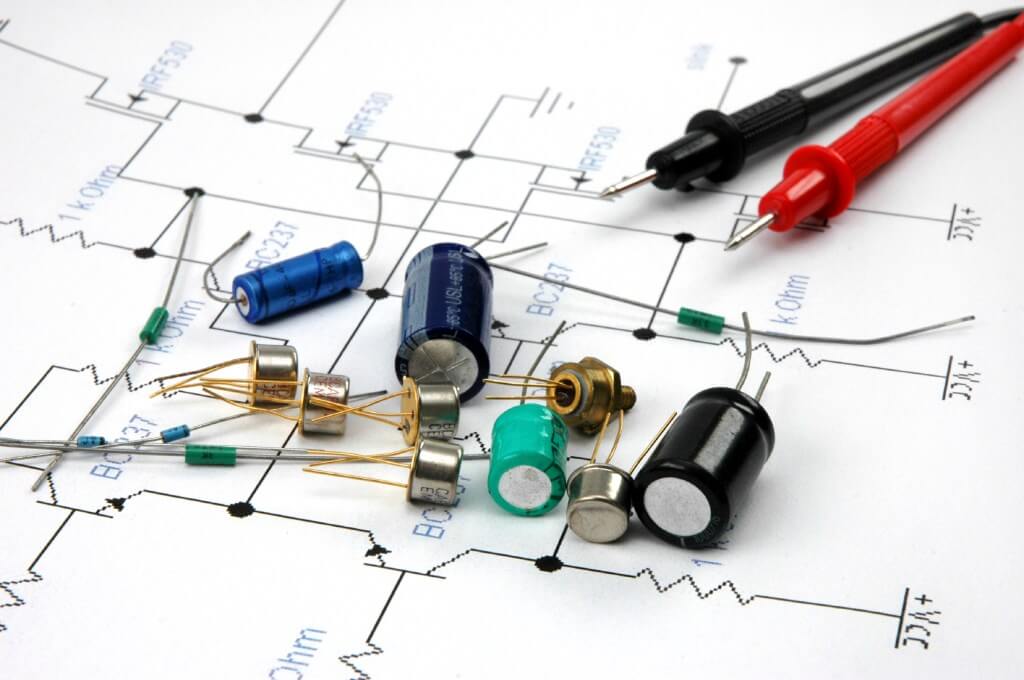

Passive parts don't need power to function, such as resistors, capacitors, and inductors. Resistors control the flow of electricity in a circuit, while capacitors store and release electrical energy. Inductors are used to filter electrical signals.

Active components, on the other hand, require a power source to function, and they include transistors, diodes, and integrate circuits (ICs). People use transistors to amplify or switch electronic signals, and diodes let current flow in only one direction. Integrate circuits or chips consist of millions of transistors and other components. They perform complex functions in electronic devices.

Electromechanical parts are parts that use movement to control electricity. They include switches, relays, and connectors. Switches turn circuits on and off, while relays switch electrical circuits on and off remotely. Connectors are used to connect different parts of an electronic circuit.

Circuit boards are vital parts of electronic devices that help electricity flow between different parts. Passive parts don't make electrical signals stronger or control them, while active parts do. In this article, we'll look at the different kinds of circuit board parts and what they do.

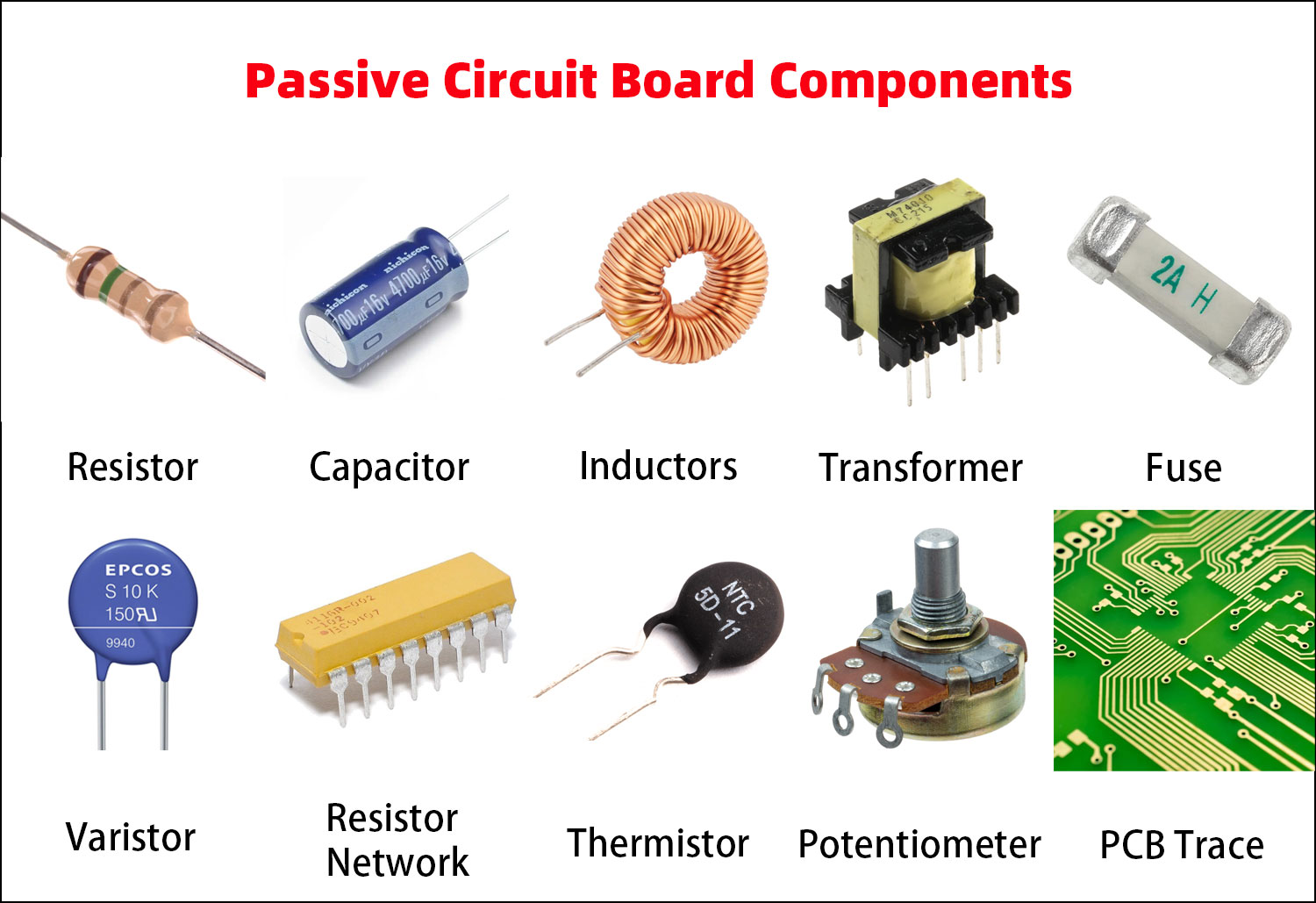

Passive components are electronic components that do not require a power source to function. They are called passive components because they do not have the ability to amplify or switch signals.

Passive parts are important pieces of circuits that don't create energy but hold, weaken, or clean signals.

Resistors - Resistors are simple parts that control the flow of electricity in a circuit. These devices change the brightness of LEDs, split voltage, and measure the amplification of signals.

Capacitors - Capacitors are passive components that store electrical charge and are commonly used to filter out high-frequency noise from power supplies and signals, create resonant circuits, and stabilize the output of voltage regulators.

Inductors - Inductors store energy in a magnetic field and people widely use them in power supplies, filters, and RF circuits.

Transformers - Transformers transfer electrical energy from one circuit to another through magnetic coupling. They are commonly used in power supplies and audio amplifiers.

Fuses - Passive components call fuses to protect electronic circuits from overcurrent conditions by breaking the circuit when the current exceeds a certain threshold.

Varistors - Varistors protect electronic circuits from voltage surges and spikes. They are passive components.

Resistor Networks - Resistor groups are simple components that contain many resistors in one package. They are frequently used in digital circuits and accurate measurement applications.

Thermistors - Passive components call thermistors measure temperature by changing resistance in response to temperature changes.

Potentiometers - Potentiometers are used in audio systems to adjust volume and tone by creating variable resistance.

PCB Traces - Passive components call PCB traces connect other components in a circuit. Manufacturers print them onto the surface of the PCB using copper.

Here are the factors to consider when selecting passive components:

Resistance Value: The resistance value of a resistor is a crucial factor to consider when selecting passive components. The value determines how much current can flow through the circuit and affects the overall performance of the circuit.

Tolerance: Tolerance refers to the range of values that a resistor can have and still be considered functional. A lower tolerance value means that the resistor is more precise, which is important for circuits that require a high degree of accuracy.

Power Rating: The power rating of a resistor tells us how much power it can handle before getting too hot or breaking. To make sure the circuit lasts a long time and the parts don't break, it's important to choose a resistor with a high enough power rating.

Capacitance Value: The capacitance value of a capacitor is a critical factor to consider when selecting passive components. It determines how much charge the capacitor can store and affects the overall performance of the circuit.

Voltage Rating: The voltage rating of a capacitor determines the maximum voltage that it can handle without breaking down. Selecting a capacitor with a high enough voltage rating is crucial to prevent component failure and ensure the long-term reliability of the circuit.

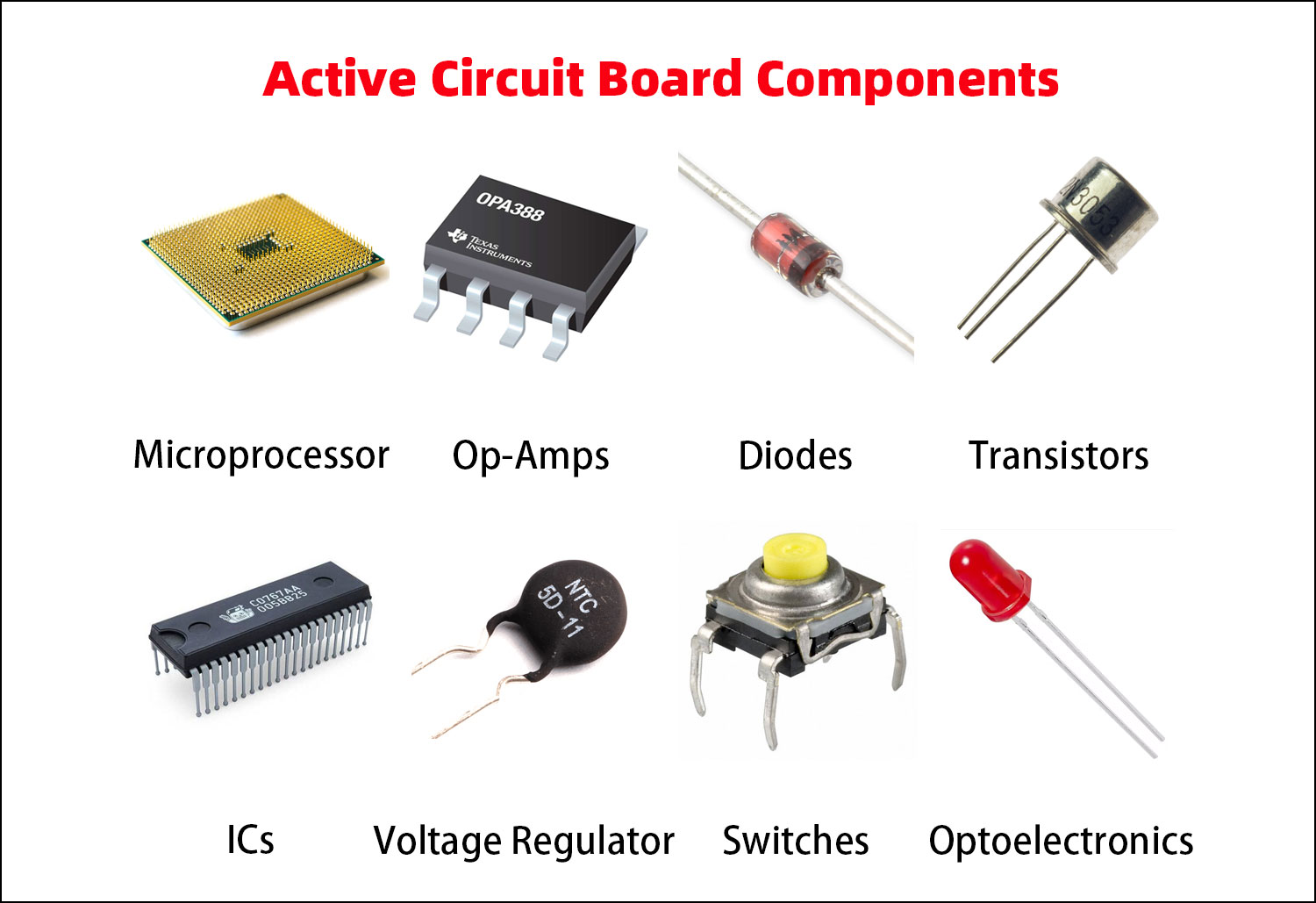

Active components are electronic components that require a power source to function. They are called active components because they have the ability to amplify or switch signals.

Active components are electronic devices that can amplify or control electrical signals. They require an external power source to operate and include diodes, transistors, and integrated circuits.

Microprocessors - Active components call microprocessors control a wide range of electronic systems, from appliances and toys to industrial machinery and medical devices.

Operational Amplifiers (Op-Amps) - Op-Amps amplify voltage with high gain and have a wide range of applications such as analog signal processing, filtering, and control.

Diodes - Diodes, which are electronic components that allow current to flow in one direction only, are considered active components due to their ability to control the flow of electrical signals and regulate voltage levels, and as such, they are employe in a wide range of applications across various industries such as electronics, telecommunications, and power distribution, for tasks that include rectification, signal modulation, and voltage regulation.

Transistors - Transistors are active components that are used to amplify or switch electronic signals. They are commonly used in digital circuits and power supplies.

Integrate Circuits (ICs) - ICs are miniaturizing electronic circuits that can contain thousands or even millions of electronic components on a single chip. They perform various functions including amplification, switching, processing, and control.

Voltage Regulators - Voltage regulators are active components that maintain a constant output voltage, regardless of changes in input voltage or load current.

Switches - Active components called switches to connect or disconnect circuits. They commonly control power to devices or select different functions or modes of operation.

Optoelectronics - Optoelectronics are active components that convert light into electrical signals or vice versa. Examples include light-emitting diodes (LEDs), photodiodes, and photoresistors.

Purpose: The first factor to consider is the purpose of the circuit board and the function that the active component will perform. Different types of active components are suited for different purposes, such as amplification, rectification, and signal processing.

Power requirements: The power requirements of the circuit board will determine the type of active component required. High-power circuits will require active components with a higher power rating, while low-power circuits can use smaller components.

Voltage rating: The voltage rating of the active component must be suitable for the voltage range of the circuit board. If the voltage rating is too low, the part will fail and potentially damage the circuit board.

Temperature range: Active components can generate heat during operation, and it is essential to select components with a temperature rating that is compatible with the operating temperature range of the circuit board.

Speed requirements: The speed requirements of the circuit board will determine the type of active component required. High-speed circuits will require active components with a higher operating frequency and faster response times.

Size and packaging: The physical size and packaging of the active component will determine how it can be mounted on the circuit board. The package type must be compatible with the layout and design of the circuit board.

Circuit board parts are important pieces of electronic devices that help electricity move around. Passive parts hold, weaken, or clean up signals, while active parts make signals stronger or help manage them. The main types of passive parts are resistors, capacitors, and inductors, and active parts include diodes, transistors, and integrated circuits. Knowing how these parts work and what they're good for is crucial for making electronic devices that people want to buy today.

Circuit board components are essential for the functioning of electronic devices. These components are responsible for controlling the flow of electricity and carrying out specific functions within a circuit. Here are some reasons why circuit board components are so important:

Circuit board components ensure that electronic devices operate reliably and accurately. Each component has a specific task to perform. If any component fails, it can disrupt the entire circuit and cause the device to malfunction or fail completely.

The size of electronic devices has decreased significantly over the years, and circuit board components have played a crucial role in making this possible. By using smaller and more efficient components, manufacturers can create devices that are compact, lightweight, and easier to transport.

Using standardized circuit board parts has made electronic gadgets cheaper. Manufacturers can reduce production costs by using commonly available components, which means gadgets are now more affordable for customers.

Manufacturers can create unique devices that meet the needs of their customers by customizing circuit board components to fit specific applications. This flexibility also allows for the development of new technologies and innovations that can improve the performance of electronic devices.

Circuit board components are subject to rigorous quality control standards to ensure that they meet specific performance and safety requirements. These standards help to ensure that electronic devices are safe to use and reliable.

circuit board components are critical to the functioning of electronic devices. These components allow for reliable operation, efficient use of space, cost-effectiveness, flexibility, and quality control. As technology continues to advance, the importance of circuit board components will only continue to grow, and new innovations in this field will enable the development of even more advanced and sophisticated electronic devices.

Circuit board components are designed to be very small in size, which makes them easy to place in a compact manner. Small electronic devices like smartphones, wearables, and other portable devices benefit greatly from this, as it saves space. The small size also allows for more efficient use of available space within the device, which can lead to a more optimal design.

Circuit board parts are made to be easy to change and fix. This saves money because it's cheaper to maintain and repair electronics. Since the parts are all the same, it's easy to find new ones, and repair people can easily figure out and fix problems. This saves time and money in the long run by reducing the need for expensive fixes or replacements.

Circuit board parts are made very accurately so they work correctly. This is super important because even tiny differences can mess up electronic devices. These parts are designed to work really well so electronic devices can work at their best.

Electronic parts on circuit boards are made in big amounts, which makes it cheaper to make electronic devices. This means people and companies can buy them at lower prices. Plus, making lots of these parts helps to save money due to the big amount made.

Designers create circuit board components for optimal function, ensuring peak performance levels in electronic devices. This is especially important for devices that require high precision and accuracy, such as medical equipment, aerospace technology, and military equipment. By using circuit board components, these devices can perform at their best, which can have significant benefits in terms of safety, reliability, and efficiency.

The design of circuit board parts cannot easily be changed to meet specific requirements. This is a problem for industries like aerospace and the military that need unique parts. It's also tough for businesses that want specific features in their electronics.

Making circuit board components is expensive at first. This is hard for small manufacturers. Buying materials and machines, hiring skilled workers, and setting up a production line cost a lot, especially for new or small businesses. This can make it tough for them to compete with bigger businesses.

Making circuit board parts creates a lot of garbage that can harm nature. Using dangerous chemicals like lead, mercury, and cadmium can pollute and harm the environment. It's tough to throw away electronic waste because it often has dangerous stuff in it that can hurt people and the environment.

Fixing broken circuit board parts is hard because they're tiny and complicated. It can be tough for regular folks to figure out what's wrong and fix it. This can make fixing the device take longer, cost more money, and sometimes you have to replace the whole thing.

The inflexibility of circuit board components limits the ability to adjust the design of electronic devices after manufacturing. This can be a problem for industries that require a high degree of flexibility in their products, such as consumer electronics or medical devices. It can also be a challenge for businesses that need to make changes to their products quickly and efficiently in response

When making a circuit board, picking the right parts is crucial for making sure the board works well and doesn't fail. Here are the important things to think about when choosing components for a circuit board:

The size and shape of components can have a significant impact on the size of the final circuit board. Smaller components allow for more compact board designs, which can be particularly important in applications where space is at a premium, such as in wearable technology or small IoT devices. However, smaller components can be more difficult to work with during assembly, and they may also have lower power ratings or be more expensive.

When selecting components for a circuit board, it's crucial to choose parts that can handle the required power and voltage levels. Components that can't handle the necessary power may overheat or fail, causing the circuit to malfunction or even damage the board. Similarly, choosing components with insufficient voltage ratings can lead to electrical breakdown or other failures.

The temperature range of components is another critical factor to consider. Some components can operate only within a narrow range of temperatures, while others can handle a much wider range. Choosing components that can handle the expected temperature extremes of the circuit board's intended application is essential for ensuring the board's reliability.

Choosing circuit board parts that are tough and dependable is crucial, particularly if the board will be subjected to frequent use or harsh conditions. Choosing dependable brands with a track record of producing high-quality parts can guarantee that the board functions properly for its expected lifespan.

When making a circuit board, cost matters. Picking affordable parts that fit the budget is a must. But, remember that less expensive parts may not be the best. They might not last long or work well. It's better to spend more on high-quality parts to guarantee the board works correctly and lasts longer.

To make sure a circuit board works well and lasts a long time, it's important to pick the right parts. Look at things like how big and strong the parts are, how much power they need, how well they work at different temperatures, and how much they cost. Choose parts from good companies that make good quality parts. When you consider all these things, you can make a circuit board that works well for what you want and will last a long time.

When choosing parts, it's important to think about if they're easy to find. If they're hard to find, it can slow down making the product. So, it's smart for the designer to choose parts that many suppliers carry. This way, there won't be problems with getting the parts.

The performance of components should meet the requirements of the final product. The designer should select components that provide the desired functionality, speed, and accuracy required for the application.

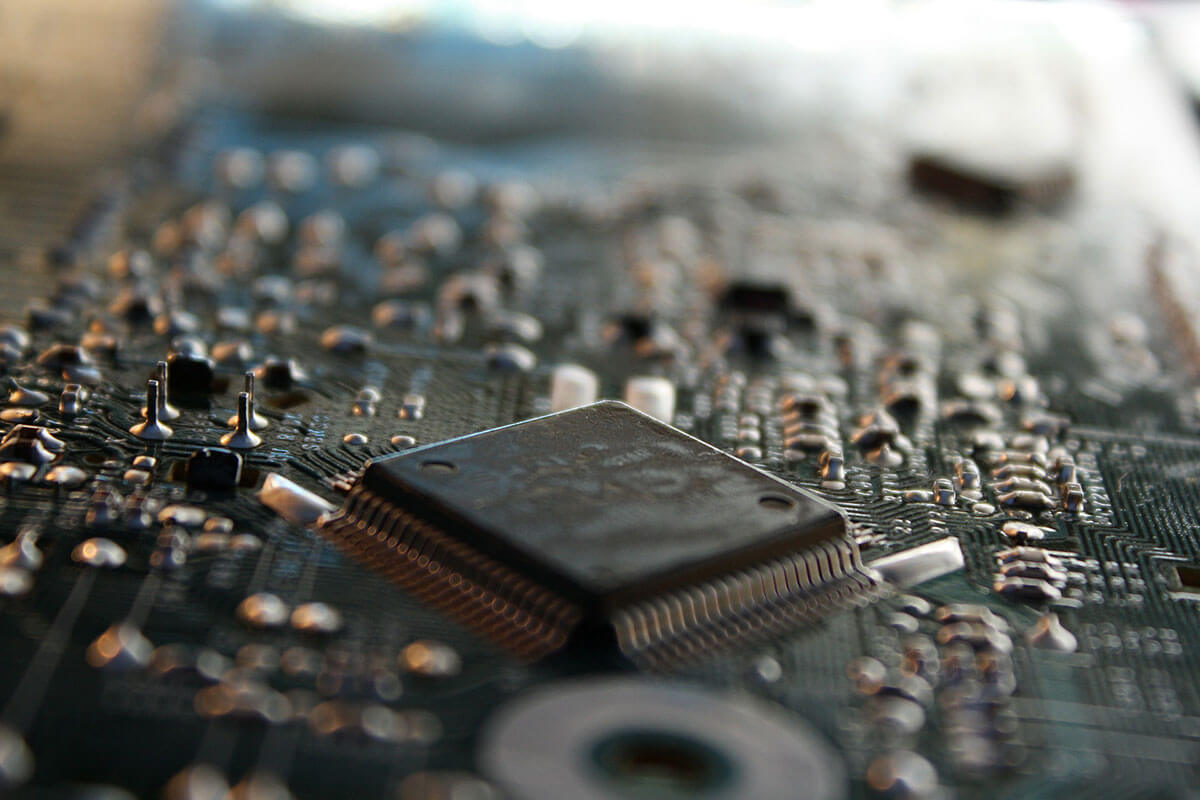

Printed circuit board (PCB) components can age due to various reasons. Age-relate failures can occur during the manufacturing process or after a prolonged period of use.

PCBs (printed circuit boards) can stop working because they're old. This can make them not work right. When PCBs get old, parts like diodes, transistors, and transformers can also break and not work right. These parts usually last around 10 years. So, after 10 years, it might be time to replace them so everything works as it should.

It's hard to stop printed circuit board parts from getting old, but replacing them is expensive. To stop PCB parts from aging, use good quality materials when making them. Also, put the parts in the right place, and don't use burned parts. If you use burned parts, they might get old fast.

To avoid rapid aging, employ the best soldering techniques during the assembly process. Chemical or fluid leakage during soldering can also cause aging. Proper care should be taken to prevent such leaks.

To prevent PCB aging, here are some tips to consider:

Use high-quality materials during PCB manufacturing: High-quality materials are less likely to degrade and malfunction quickly, leading to less aging.

Proper component placement: Correctly placing components is important to prevent stress and extend their lifespan.

Avoid burn components: Burne components will age quickly, leading to premature failure. Therefore, it's crucial to avoid using burned components during assembly.

Employ the best soldering techniques: The use of proper soldering techniques will prevent unnecessary stress on the components, leading to less aging.

Avoid chemical or fluid leakage during soldering: Chemical or fluid leakage during soldering can cause aging, leading to premature failure. Proper care should be taken to prevent such leaks.

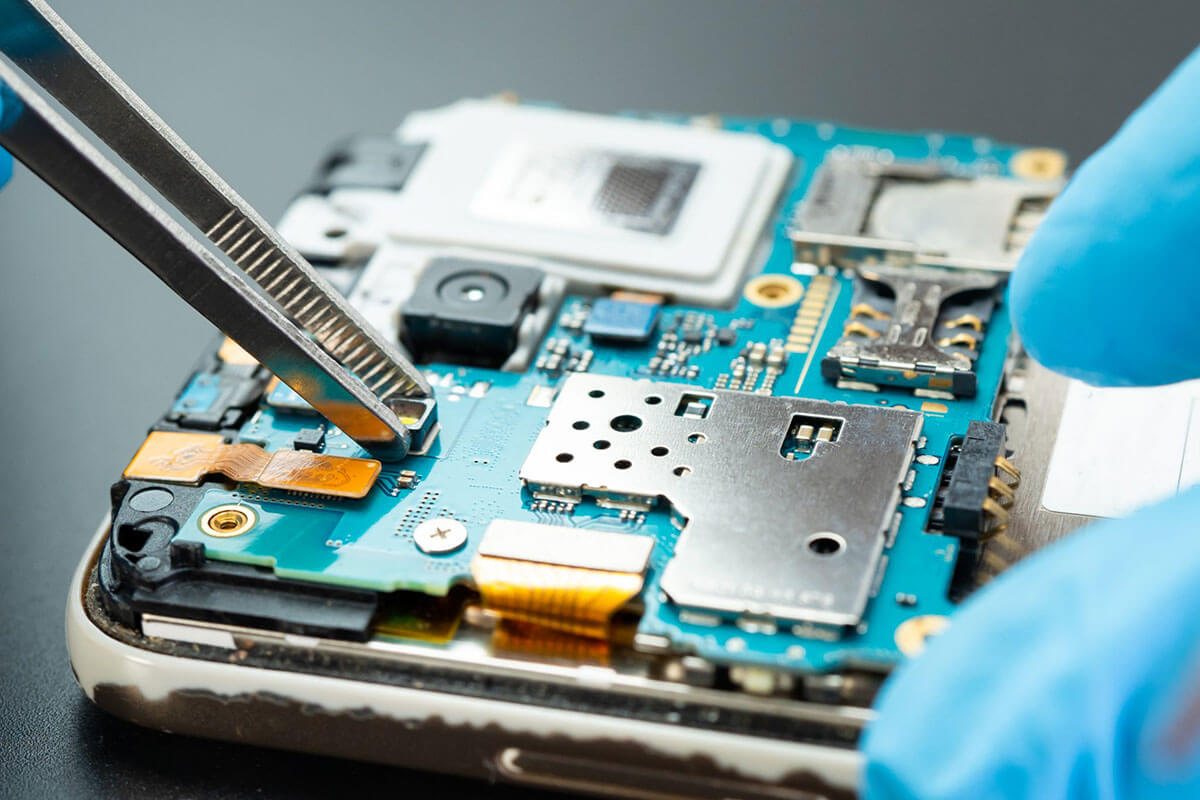

Parts on a Printed Circuit Board (PCB) are linked in different ways depending on the component type, the required electrical connection, and the space on the board. Below are some common ways of connecting components on a PCB:

Surface Mount Technology (SMT) is a method of linking small parts like resistors, capacitors, and integrated circuits to a PCB. We join SMT parts with metal tabs or balls on the bottom straight to copper pads on the PCB. Usually, automated machines are used to quickly and accurately place and solder the parts onto the board.

SMT saves space and lets you make smaller, more compact PCB designs.

"Through Hole Technology (THT): This way is for bigger parts like plugs, buttons, and power suppliers.

The wires are inserted into pre-made holes in THT pieces and then soldered onto copper spots on the opposite side of the board. This method gives a firm and robust connection, but it uses up more room on the PCB and takes more time to put together."

Pin Grid Arrays (PGAs): These are used for high-density components like microprocessors and memory chips. Soldering directly to the copper pads on the PCB, the grid of small pins in PGAs provides a very secure connection and enables a large number of pins to connect to the board in a small space.

Electronics or engineering terminology. "Ball Grid Arrays," "high-density components," "microprocessors," "graphics chips," "copper pads," and "specialized equipment" are all technical terms that may require additional explanation for some readers.

Overall, the method used to connect components on a PCB will depend on the type of component, the desired electrical connection, and the available space on the board. PCB designers must carefully consider these factors when choosing the most appropriate method for connecting components on a given board.

As technology continues to evolve, the demand for smaller, more powerful, and more efficient circuit board components is increasing. Consequently, some of the future trends in circuit board components are:

The use of AI and IoT is growing, resulting in the development of specialized parts for handling and studying big data.

As we need to process things faster, we'll need more powerful parts that work faster. That means we'll have to make new stuff that can handle higher speeds without getting worse.

The trend for saving energy will continue, requiring improved parts that can handle higher voltage but use less power.

The integration of multiple functions into a single component will become more common. We need new ways of making things that can do more than one thing, but still, work well and are dependable.

NextPCB makes good circuit board parts and has many advantages for your component needs.

NextPCB is a company that makes top-notch printed circuit boards (PCBs) for different industries. They use modern methods and tests to make sure their products are up to par with industry standards. This means customers can trust that their parts will work well. The company has a team of skilled engineers who know how to design and create PCBs for various uses.

NextPCB simplifies the PCB ordering process with its quick and easy-to-use PCB quote service. Customers can get instant quotes based on their specific requirements, making it convenient to plan and budget their PCB projects. With transparent pricing and quality assurance, NextPCB ensures a smooth and reliable PCB manufacturing experience.

NextPCB also provides professional PCB assembly services, offering end-to-end solutions for customers' electronics manufacturing needs. Their experienced team ensures the highest level of quality and efficiency throughout the assembly process, providing seamless integration of components into the circuit board.

NextPCB's Gerber Viewer is an essential tool for PCB designers and engineers. It allows users to view and analyze Gerber files, ensuring the accuracy and correctness of their PCB designs before manufacturing. This free online tool offers convenience and confidence in the PCB manufacturing process.

They know that in today's fast business world, time is important, and delays can be bad. So, they work quickly on urgent projects without sacrificing quality.

NextPCB lets you make your own printed circuit board (PCB) by choosing how it looks, picking what parts to use, and even getting help putting it all together. Furthermore, this means that you can tailor your components to meet your specific requirements.

NextPCB provides technical support to their customers, including assistance with design and manufacturing issues. This can be very useful if you have any issues while making the product.

NextPCB cares deeply about sustainability. They make an effort to use materials and methods that are good for the environment whenever they can, to show how much they care about sustainability.

As tech gets better, people want tinier, better parts. So, companies making stuff have to keep up with the newest ways to make circuit boards or they'll fall behind. They also need to put money into exploring and making new materials and methods to keep up with what the industry wants.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|